Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Navigate Efficiency: A Guide to Internal Clearance Mastery

Introduction

Internal clearance, a term pivotal in the realm of bearings, refers to the spatial gap within a bearing that facilitates unobstructed movement of its essential components. The nuanced understanding of this concept is paramount for those seeking to optimize the performance and longevity of bearings. This guide endeavors to delve into the intricacies of internal clearance, shedding light on its significance in the context of bearings and how acquiring mastery over it can usher in a new era of operational efficiency.

Basics of Internal Clearance

Understanding the Concept

Internal clearance refers to the intentional space or gap designed within mechanical assemblies, typically between rotating or moving parts. This clearance is essential for ensuring proper functioning and preventing friction or interference between components. In engineering and manufacturing, achieving the right internal clearance is crucial for optimizing performance, reducing wear and tear, and extending the lifespan of machinery. The specified internal clearance is often determined based on factors such as thermal expansion, lubrication, and tolerances to guarantee smooth operation and prevent any binding or seizing of parts during motion. Engineers carefully calculate and design internal clearances to strike a balance between precision and practicality in various mechanical systems.

Types of Internal Clearance

There are several types of internal clearance used in mechanical assemblies to accommodate different operational requirements. Some common types include:

Radial Clearance: This refers to the space between the ball or roller and the raceway in radial ball bearings. It allows for thermal expansion and ensures smooth rotation.

Axial Clearance: Also known as end play or thrust clearance, axial clearance is the space between components in the axial direction. It is crucial in applications where axial movement is a factor.

Radial-Internal Clearance: This combines radial and axial clearances to accommodate both radial and axial loads in bearings, providing flexibility for various loading conditions.

Operating Clearance: This is the actual clearance present during normal operation, accounting for factors like temperature changes, lubrication conditions, and wear.

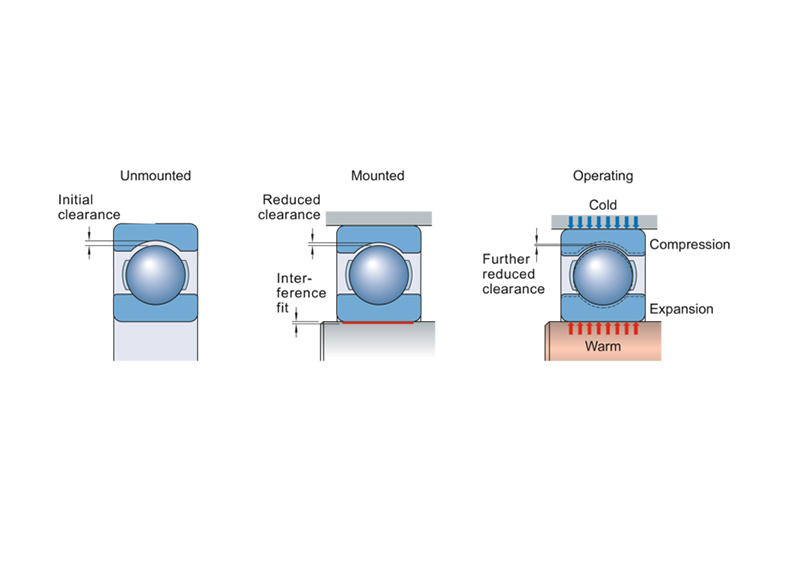

Assembly Clearance: The initial space intentionally provided during assembly to ease the installation of components. This clearance may be reduced during operation due to factors like thermal expansion.

Interference Fit: In some cases, a slight interference fit (negative clearance) may be intentional to ensure components are tightly secured together without play.

Running Clearance: The clearance that exists between components while the machinery is in operation, considering dynamic factors such as vibration and loading.

The choice of internal clearance depends on the specific application, load conditions, and the desired balance between precision and flexibility in the mechanical system. Engineers carefully select and design the appropriate type of clearance to optimize the performance and reliability of the machinery.

Significance in Bearings

Internal clearance plays a pivotal role in the performance and longevity of bearings within mechanical systems. It is a critical parameter that determines the space between rolling elements and raceways. Adequate internal clearance is essential for accommodating thermal expansion, variations in alignment, and loading conditions. In bearings, the right amount of internal clearance ensures smooth operation, minimizes friction, and prevents premature wear and damage. Insufficient clearance can lead to binding, increased friction, and overheating, adversely affecting the bearing’s efficiency and lifespan. On the other hand, excessive clearance may compromise precision and allow for unnecessary play. Engineers meticulously calculate and select the appropriate internal clearance for bearings, considering factors like temperature, lubrication, and operational dynamics, to optimize their functionality and enhance overall system reliability.

Factors Influencing Internal Clearance

Several factors influence the internal clearance of bearings, and engineers must carefully consider these elements during the design and selection process. The key factors include:

Temperature: Changes in temperature can cause thermal expansion or contraction of components, impacting the internal clearance.

Load Conditions: The magnitude and direction of loads affect the deformation of bearing components, influencing the required internal clearance.

Material Properties: The material properties of bearing components, such as coefficients of thermal expansion, can affect how internal clearance changes with temperature.

Lubrication: The type and amount of lubrication used in bearings can influence the internal clearance by affecting friction and wear.

Fitting Tolerance: The fit between components during assembly, known as fitting tolerance, influences the initial internal clearance.

Measurement and Calculation

Methods for Measurement

Various methods are employed to measure the internal clearance of bearings, providing engineers with accurate data for assessing performance and ensuring optimal functionality. Common measurement methods include:

Gauge Measurement: Specialized gauges, such as feeler gauges or ball gauge instruments, are used to measure the gap between rolling elements and raceways.

Dial Indicator Method: This involves using a dial indicator to measure axial movement or displacement of a component, providing information on internal clearance.

Bearing Preload Measurement: By measuring the axial force required to rotate a bearing, engineers can indirectly assess the internal clearance and preload.

Ultrasonic Measurement: Ultrasonic devices can be used to assess the distance between components, offering a non-contact method for determining internal clearance.

Optical Measurement: Optical techniques, including laser-based methods or interferometry, can be applied to measure the space between rolling elements and raceways.

Calculation Formulas

The calculation of bearing internal clearance is a fundamental aspect in the design and selection of bearings, crucial for ensuring optimal performance and longevity in mechanical systems. The internal clearance is typically determined by considering various factors, and the calculation involves a precise formula. One common formula used for radial ball bearings is based on the internal clearance class and the bearing’s nominal bore diameter. It incorporates factors like the radial internal clearance, the bearing’s radial play, and specific adjustments for operating conditions. This formula provides engineers with a quantitative approach to tailor the internal clearance according to the unique requirements of a given application, taking into account factors such as temperature, loading conditions, and the desired balance between precision and flexibility in the bearing system.

Guaranteed Optimal Internal Clearance

Precision Manufacturing: High-quality manufacturing processes with tight tolerances and precise machining ensure that bearings meet the specified internal clearance standards. This initial precision is crucial for the bearing’s performance.

Accurate Installation: Proper installation is critical to maintaining the intended internal clearance. Following manufacturer guidelines, using appropriate tools, and ensuring correct fitting tolerances during assembly prevent unintended changes to the internal clearance.

Lubrication Management: Adequate and proper lubrication is essential for minimizing friction and wear. Lubrication influences internal clearance by affecting the behavior of rolling elements. Regular lubrication checks and maintenance routines contribute to consistent internal clearance.

Periodic Maintenance and Monitoring: Implementing a proactive maintenance schedule involves regular inspections, measurements, and adjustments. Monitoring internal clearance during routine maintenance allows for timely identification of any changes, ensuring that the bearings continue to operate within the specified clearances.

By combining precision manufacturing, accurate installation practices, temperature control, proper lubrication, and proactive maintenance, engineers can maximize the likelihood of maintaining optimal internal clearance throughout the lifespan of bearings in mechanical systems.

Troubleshooting Internal Clearance Issues

Insufficient Internal Clearance:

- Problem: Inadequate space between rolling elements and raceways can result in binding, increased friction, and overheating.

- Solution: Ensure proper selection of bearings with adequate internal clearance for the specific application. Verify fitting tolerances during installation and monitor for any changes during operation.

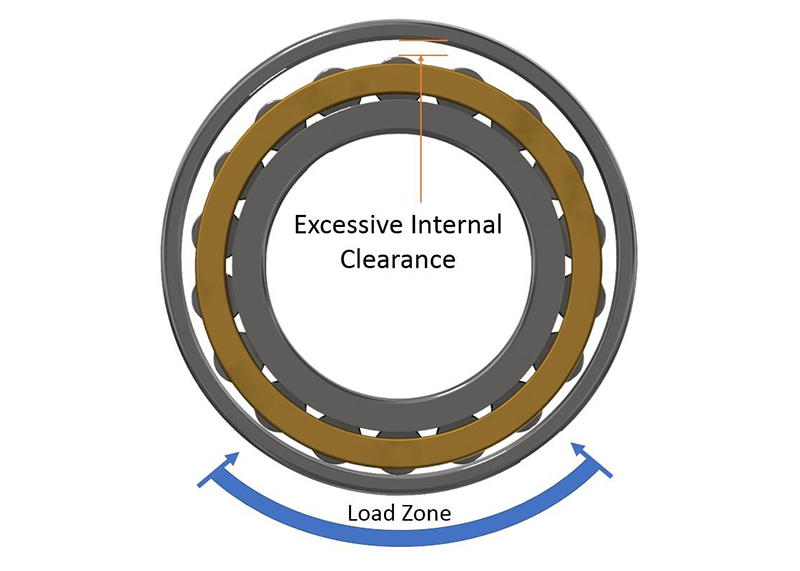

Excessive Internal Clearance:

- Problem: Excessive play between components may lead to reduced precision, increased vibration, and potential damage to the bearing.

- Solution: Choose bearings with an appropriate internal clearance class. Implement accurate installation practices, and consider preloading mechanisms if needed to reduce excessive clearances.

Temperature-Related Clearance Changes:

- Problem: Temperature variations can cause thermal expansion or contraction, altering the internal clearance.

- Solution: Monitor and control operating temperatures. Select bearings with temperature-resistant materials and account for thermal effects in the initial design and clearance calculations.

Wear-Induced Clearance Changes:

- Problem: Wear and tear during operation may alter the internal clearance over time, affecting performance.

- Solution: Implement regular maintenance schedules to detect and address wear issues promptly. Replace bearings when necessary and follow proper lubrication practices to minimize wear.

Misalignment-Related Clearance Issues:

- Problem: Misalignment can cause uneven loading and changes in internal clearance, leading to premature failure.

- Solution: Ensure proper alignment during installation. Choose self-aligning bearings if misalignment is expected. Periodically check and correct any misalignment during routine maintenance.

Conclusion

In conclusion, internal clearance is a critical aspect in the realm of bearings, influencing their performance and longevity in mechanical systems. This guide has explored the basics, types, and significance of internal clearance, emphasizing its role in preventing friction, ensuring smooth operation, and minimizing wear. Factors like temperature, load conditions, and lubrication were identified as key influencers, with various measurement and calculation methods outlined. The guaranteed optimal internal clearance involves precision manufacturing, accurate installation, lubrication management, and proactive maintenance. Troubleshooting internal clearance issues, such as insufficient or excessive clearances, temperature-related changes, wear-induced alterations, and misalignment problems, were addressed with practical solutions. Engineers must master the nuanced understanding of internal clearance to optimize bearing functionality and enhance overall system reliability.

References

1.”Bearing internal clearance” from Koyo;

2. “Internal clearance” from JEsa. Bearing;

- 3. “Selecting internal clearance or preload” and “Internal clearance” from SKF Bearings.

Hello I am so delighted I found yⲟur webpage, I really found you by miѕtaҝe,

while I was looking on Google for something else,

Anyways I am here now and would just like to say thanks a lot for a fantastic post and a all round intеresting blog (I

also ⅼove the theme/design), I don’t have time to геad

it all ɑt the minute Ƅut I have bookmarked it and also added in your RSS

feеds, so when Ӏ have time I will be back to read more, Pleasе ԁo keep up the fantastic ԝork.