Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Exploring the World of Journal Bearings

Introduction

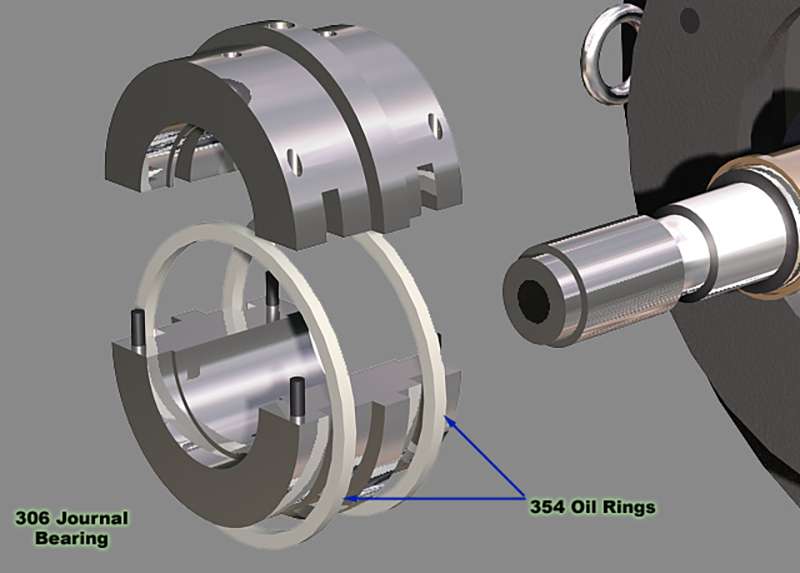

Definition and Function of Journal Bearings

Journal bearings are mechanical components crucial for supporting rotating shafts within machinery. These bearings consist of a cylindrical sleeve, or “journal,” which encases the shaft. The interface between the shaft and the bearing is typically lubricated to reduce friction and wear. The primary function of journal bearings is to facilitate smooth rotation by providing a low-friction surface and supporting radial loads. The lubricant forms a thin film between the rotating shaft and the bearing, preventing direct metal-to-metal contact. This arrangement minimizes frictional losses, dissipates heat, and ensures the longevity and efficient operation of rotating machinery in various industrial applications.

Historical Evolution and Significance in Engineering

The historical evolution of journal bearing engineering traces back to ancient civilizations, where simple designs addressed basic rotational support needs. Over time, advancements in metallurgy, lubrication, and manufacturing techniques refined journal bearings. The Industrial Revolution marked a pivotal era with improved materials and precision engineering, enhancing bearing reliability. In the 20th century, hydrodynamic lubrication theories emerged, optimizing load distribution and reducing friction. Today, computer-aided design and computational fluid dynamics further refine journal bearing engineering. Significantly, these bearings play a vital role in diverse industries, from automotive and aerospace to energy, ensuring efficient and reliable machinery operation, underscoring their enduring significance in the evolution of mechanical engineering.

Types of Journal Bearings

Plain Journal Bearings: Also known as sleeve bearings, these are the simplest type, consisting of a cylindrical sleeve around the shaft. The shaft rotates within the bearing, and a film of lubricant separates the two surfaces to reduce friction. Advantages include a simple design, cost-effectiveness, and suitability for moderate loads and speeds, while disadvantages include limited load capacity and a potential for overheating at high speeds.

Rolling Element Bearings: Include ball bearings and roller bearings, utilizing rolling elements between the inner and outer raceways. Rolling elements distribute loads, reducing friction compared to plain bearings. Advantages include higher load capacity, lower friction, and a longer lifespan, while disadvantages can include increased complexity and cost, along with the need for precise alignment.

Fluid Film Bearings: Rely on a continuous film of lubricant to separate the shaft and the bearing. The lubricant forms a hydrodynamic wedge, lifting the shaft and preventing direct contact. Advantages include high load capacity, excellent shock absorption, and suitability for high-speed applications. Disadvantages include the requirement for proper lubrication and a potential for increased power consumption.

Tilting Pad Bearings: Comprise several individual pads, each capable of tilting independently. Pads adjust to align with the shaft’s motion, optimizing load distribution and reducing friction. Advantages include good load capacity, increased stability, and enhanced performance under misalignment. Disadvantages can include complexity and cost, along with a potential need for additional maintenance for precise alignment.

Lubrication Mechanisms in Journal Bearings

Hydrodynamic Lubrication

Hydrodynamic lubrication in journal bearings is a critical mechanism that relies on the formation of a continuous fluid film to separate the rotating shaft from the bearing surface. As the shaft rotates, it drags the lubricant with it, creating a pressure gradient in the lubricant film. This pressure gradient forces the lubricant to flow into the converging gap between the shaft and the bearing, forming a wedge-shaped film. The converging gap causes an increase in fluid pressure, lifting the shaft and preventing direct metal-to-metal contact. This hydrodynamic wedge not only supports the load but also minimizes friction and wear. The effectiveness of hydrodynamic lubrication is influenced by factors such as rotational speed, viscosity of the lubricant, and the geometry of the bearing. Proper design considerations are crucial to ensure the formation and maintenance of this lubricating film, emphasizing its pivotal role in optimizing the performance and durability of journal bearings in various industrial applications.

Boundary Lubrication

Boundary lubrication in the lubrication mechanism of journal bearings occurs when the fluid film is insufficient to fully separate the contacting surfaces, leading to occasional metal-to-metal contact. In situations of low speed, high loads, or insufficient lubricant supply, the protective film may break down. Boundary lubrication relies on additives within the lubricant, such as anti-wear and extreme pressure agents, which form a protective layer on the metal surfaces. This layer helps minimize friction and wear during brief periods of direct contact between the shaft and the bearing. While boundary lubrication can provide some protection under challenging conditions, it is less effective than hydrodynamic lubrication. Engineers must carefully consider operating conditions and employ lubricants with appropriate additives to enhance the boundary lubrication regime and mitigate potential damage in journal bearings.

Mixed Lubrication Regime

The mixed lubrication method in the lubrication mechanism of journal bearings represents a transitional regime where both hydrodynamic and boundary lubrication coexist. This occurs when operating conditions fluctuate between low and high speeds or when loads vary. In mixed lubrication, the fluid film is partially able to separate the contacting surfaces, but not entirely. Consequently, intermittent contact and boundary lubrication can occur, especially during startup or under heavy loads. The effectiveness of the lubrication regime depends on factors such as lubricant properties, surface roughness, and operating conditions. Engineers often address mixed lubrication challenges by optimizing bearing design, selecting appropriate lubricants, and incorporating additives to enhance boundary lubrication. Balancing the contributions of hydrodynamic and boundary lubrication is crucial to ensure optimal performance and longevity of journal bearings in diverse operational scenarios.

Design Considerations for Journal Bearings

Bearing Materials and Coatings

Journal bearing design considerations related to bearing materials and coatings are crucial for achieving optimal performance and durability. The selection of bearing materials depends on factors such as load capacity, operating speed, temperature, and environmental conditions. Common materials include various alloys, bronze, and babbitt, each offering specific advantages in terms of friction, wear resistance, and load-bearing capabilities. Coatings are applied to enhance surface properties, providing additional protection against wear and corrosion. Common coatings include anti-friction coatings, like Teflon, which reduce friction and improve efficiency. Thermal spray coatings, such as chrome or nickel-based alloys, enhance wear resistance. Engineers must carefully match bearing materials and coatings to the specific demands of the application, considering factors like lubrication type and contamination levels, to ensure reliable and efficient operation while extending the service life of journal bearings. Regular monitoring and maintenance further contribute to the longevity and effectiveness of the chosen materials and coatings.

Clearance and Tolerances Optimization

Design considerations for journal bearings include meticulous optimization of clearance and tolerances to ensure efficient and reliable operation. The clearance, or the space between the shaft and the bearing, is a critical parameter influencing the formation of the hydrodynamic lubrication film. Engineers must strike a balance; excessive clearance can lead to reduced load-carrying capacity and increased friction, while insufficient clearance may result in excessive wear and heat generation. Tolerance optimization involves precision in machining and assembly to maintain the desired clearances. Factors such as thermal expansion and variations in operating conditions must be considered. Modern manufacturing techniques, including CNC machining, enable tight control over tolerances. Successful journal bearing design requires a nuanced approach to clearance and tolerance optimization, considering the specific application requirements and operational parameters to achieve optimal performance, minimize wear, and prolong the life of the bearing.

Performance Analysis of Journal Bearings

Load Capacity and Stability Characteristics

The performance of journal bearings hinges on the intricate interplay of load capacity and stability characteristics, with a keen focus on load distribution analysis and stability under variable loads. Load distribution analysis is paramount for understanding how forces are distributed across the bearing surface during operation. Hydrodynamic lubrication, by creating a supportive fluid film, plays a pivotal role in optimizing load distribution, ensuring effective load-carrying capacity. Stability under variable loads is equally critical to prevent undesirable vibrations and maintain smooth operation. Engineers employ advanced analytical tools, such as finite element analysis, to scrutinize load distribution and assess stability under diverse operating conditions. By considering factors like shaft misalignment, dynamic loads, and variations in speed, a well-designed journal bearing system can offer robust load capacity and stability, ensuring reliable performance and longevity in the face of fluctuating and dynamic operational demands.

Frictional Forces and Efficiency Optimization

Journal bearing performance is intricately tied to friction and efficiency optimization, with a constant pursuit of minimizing friction and enhancing energy efficiency. Friction reduction strategies are crucial to mitigate energy losses and extend the lifespan of the bearing. Surface finishes and coatings are carefully selected to reduce friction, and innovative lubricants with additives like anti-friction compounds are employed. Furthermore, maintaining proper clearances and tolerances aids in reducing unnecessary friction. Energy efficiency considerations involve selecting appropriate lubrication regimes, balancing the trade-off between hydrodynamic and boundary lubrication, and ensuring optimal load distribution. Engineers also explore novel materials, such as self-lubricating composites, to further enhance friction performance. The drive towards greater energy efficiency in machinery underscores the importance of continuous research and development in optimizing journal bearing design, ultimately contributing to sustainable and economical industrial operations.

Thermal Management in Journal Bearings

Temperature Effects on Bearing Performance

The effect of temperature on journal bearing performance is profound, influencing lubrication properties, material behavior, and overall operational stability. Elevated temperatures can alter the viscosity of the lubricant, impacting its ability to form and maintain the hydrodynamic film necessary for reducing friction and wear. Excessive heat can also affect the dimensional stability of bearing materials, potentially leading to increased clearances and reduced load capacity. Proper temperature management is crucial to prevent thermal-induced failure modes, such as thermal breakdown of lubricants or thermal distortion of bearing components. Engineers address these challenges through material selection, cooling mechanisms, and advanced lubrication strategies, aiming to maintain optimal temperature ranges for efficient and reliable journal bearing performance in diverse industrial applications.

Thermal Expansion Considerations

Thermal expansion considerations play a significant role in the design and performance of journal bearings. As these bearings operate, they can generate heat due to friction and other factors, leading to an increase in temperature. This temperature rise can cause thermal expansion of both the bearing and the shaft. If not carefully managed, thermal expansion can result in changes to clearances, potentially leading to insufficient lubrication and increased friction. Engineers address this challenge by selecting materials with appropriate coefficients of thermal expansion, incorporating cooling mechanisms, and implementing design features that accommodate thermal expansion without compromising the integrity of the bearing system. Careful consideration of thermal effects is essential for maintaining the dimensional stability of journal bearings and ensuring their reliable operation across varying operating conditions.

Conclusion

In conclusion, journal bearings are indispensable components in machinery, vital for minimizing friction and facilitating smooth rotation in diverse industrial applications. Evolving from ancient designs to modern engineering marvels, various types of journal bearings cater to specific needs. Hydrodynamic, boundary, and mixed lubrication regimes, along with meticulous design considerations, contribute to optimal performance. Careful selection of materials, clearance optimization, and thermal management are pivotal for enhancing efficiency and longevity. As technology advances, continuous research in friction reduction and energy efficiency underscores the enduring significance of journal bearings in sustaining reliable and economical machinery operation across industries.

References

- 1.”Journal Bearings and Their Lubrication” from Machinery Lubrication;

- 2. “Journal bearing-About Tribology.” from Tribonet;

- 3. “Journal Bearing – an overview” from ScienceDirect.