Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Exploring the Crucial Role of Kingpin Bearings in Automotive Suspension

Introduction

When it comes to the intricate systems that make up a vehicle, the kingpin bearing might not be the first component that comes to mind. However, this small but crucial part plays a significant role in the functioning of the automotive suspension system. In this blog post, we’ll delve into the world of kingpin bearings, exploring their functionality, history, and maintenance in automotive technology.

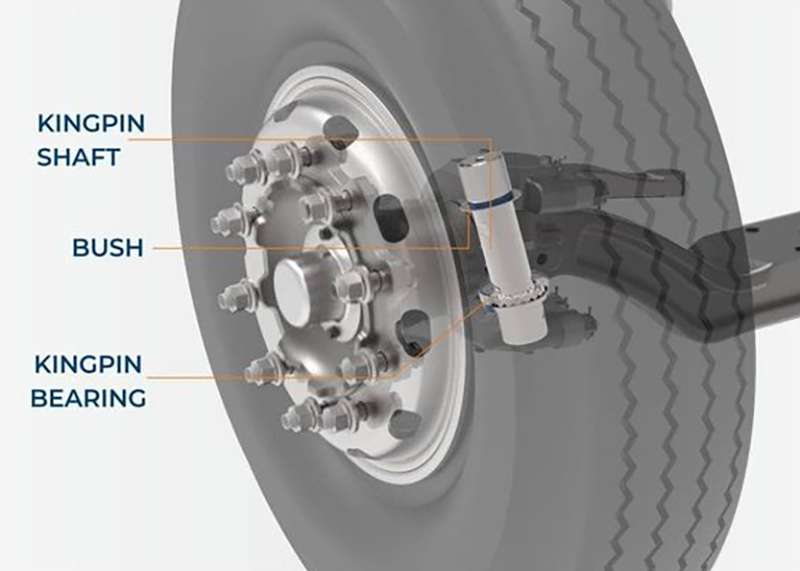

Definition of Kingpin Bearing

A kingpin bearing is a crucial component in the steering system of vehicles, especially in older designs like trucks and buses. This bearing supports the kingpin, which is the main pivot in the steering mechanism, allowing the front wheels to turn smoothly. The kingpin bearing is responsible for reducing friction and ensuring proper alignment of the steering components, contributing to stable and controlled steering. It plays a vital role in maintaining the integrity and functionality of the steering system, impacting the overall handling and maneuverability of the vehicle. Proper maintenance and lubrication of the kingpin bearing are essential to ensure safe and efficient operation of the vehicle on the road.

Importance in Automotive Suspension

Kingpin bearings are integral to the suspension system of automobiles, serving as a critical link between the steering and suspension components. These bearings facilitate the smooth rotation of the kingpin, which is essential for proper steering control and stability. By reducing friction and allowing the kingpin to pivot effectively, these bearings ensure that the wheels can turn smoothly, enhancing maneuverability and overall driving performance. Additionally, kingpin bearings help distribute the weight of the vehicle evenly across the suspension, contributing to a comfortable ride quality and minimizing wear on other suspension parts. Maintaining these bearings is crucial for ensuring safe handling, optimal suspension function, and overall vehicle safety on the road.

Basics of Kingpin Bearings

Functionality

Kingpin bearings play a crucial role in the functioning of a vehicle’s suspension system, particularly in the context of trucks and other heavy-duty vehicles. These bearings are integral components within the kingpin assembly, connecting the steering knuckle to the axle’s spindle. Serving as a pivot point for the front wheels, kingpin bearings facilitate smooth and controlled steering movements. Their primary function is to allow the wheel to pivot left and right, enabling the vehicle to change direction effectively. The design and quality of kingpin bearings directly impact the stability and maneuverability of the vehicle. Properly functioning kingpin bearings ensure precise and responsive steering, contributing to overall road safety and vehicle performance. Regular inspection and maintenance of these bearings are essential to prevent wear and tear, ensuring optimal functionality and extending the lifespan of the suspension system.

Types of Kingpin Bearings

The two primary types of kingpin bearings are tapered roller bearings and ball bearings, each contributing to the functionality of a vehicle’s suspension system in distinct ways. Tapered roller bearings consist of cone and cup assemblies, where the conical shape enables them to handle both radial and axial loads efficiently. This design provides increased stability and durability, making tapered roller bearings well-suited for heavy-duty applications such as trucks and commercial vehicles. On the other hand, ball bearings utilize spherical elements to facilitate smooth rotation between the kingpin and the steering knuckle. Known for their reduced friction and precise movement, ball bearings are commonly found in modern passenger cars, offering responsive steering and improved handling. The choice between tapered roller bearings and ball bearings depends on factors like vehicle type, load requirements, and desired performance characteristics, showcasing the importance of selecting the appropriate kingpin bearing type to optimize the overall suspension system performance.

History of Kingpin Bearings

The history of kingpin bearings can be traced back to the early 20th century when automotive engineering was in its nascent stages. Early designs primarily featured simple bushings, often made of brass or bronze, providing a basic but effective pivot point for the steering mechanism. As vehicle technology advanced, the introduction of tapered roller bearings in the mid-20th century marked a significant leap forward. This design innovation allowed for enhanced load-bearing capabilities and improved durability, particularly in heavy-duty applications like trucks. Subsequent technological advances brought about the integration of ball bearings, offering reduced friction and increased precision in steering components. Over the years, the evolution of materials and manufacturing processes has continually refined kingpin bearing designs, contributing to the efficiency, durability, and overall performance of suspension systems in a wide range of vehicles.

Significance in Vehicle Steering

Steering Mechanism

The kingpin bearing stands as a pivotal component in the steering mechanism of vehicles, playing a crucial role in determining the efficiency and control of the entire system. Serving as the linchpin between the steering knuckle and the axle’s spindle, the kingpin bearing enables the controlled rotation of the front wheels, influencing the vehicle’s overall maneuverability. Its significance lies in providing a stable pivot point that allows for precise steering movements, essential for navigating turns, corners, and maintaining a straight trajectory. The choice of kingpin bearing type, be it tapered roller bearings or ball bearings, directly impacts the responsiveness, durability, and load-bearing capacity of the steering system. As a cornerstone of automotive suspension, the kingpin bearing’s proper functioning ensures not only the driver’s comfort but also contributes significantly to road safety and the overall performance of vehicles across various applications.

Role in Handling and Control

The kingpin bearing plays a pivotal role in determining the handling and control characteristics of a vehicle, influencing its ability to navigate smoothly and respond to driver inputs effectively. Situated at the core of the steering mechanism, the kingpin bearing facilitates controlled movement of the front wheels, directly impacting the vehicle’s overall handling dynamics. The precise rotation enabled by the kingpin bearing is crucial for executing turns, maintaining stability during maneuvers, and ensuring a responsive steering system. Whether it’s the robustness of tapered roller bearings or the reduced friction of ball bearings, the type of kingpin bearing employed significantly influences the vehicle’s ability to handle varying road conditions and maintain optimal control. The proper functioning of the kingpin bearing contributes to a harmonious interaction between the driver and the vehicle, enhancing not only the driving experience but also promoting safety and control on the road.

Common Issues and Maintenance

Wear and Tear: Over time, kingpin bearings can experience wear and tear due to constant movement and heavy loads.Maintenance Method: Regular inspections are essential to identify signs of wear early. Timely replacement of worn bearings is crucial to prevent further damage and ensure optimal performance.

- Corrosion: Exposure to environmental elements can lead to corrosion, potentially compromising the structural integrity of kingpin bearings. Maintenance Method: Implementing corrosion-resistant coatings, regular cleaning, and applying protective measures, such as grease or oil, can help mitigate corrosion risks.

Inadequate Lubrication: Insufficient or degraded lubrication can result in increased friction, heat generation, and accelerated wear of kingpin bearings. Maintenance Method: Following the manufacturer’s recommended lubrication schedule and using high-quality lubricants are vital to maintaining proper functioning. Regular greasing or oiling should be part of routine maintenance.

Misalignment: Misalignment of the kingpin bearings can lead to uneven wear and affect steering responsiveness. Maintenance Method: Periodic checks for proper alignment and adjustment are essential. If misalignment is detected, corrective measures should be taken promptly to prevent further issues.

Loose Fasteners: Loose bolts and fasteners in the kingpin assembly can result in play and compromise the stability of the steering system. Maintenance Method: Regularly inspecting and tightening fasteners is crucial. Following the manufacturer’s torque specifications during assembly and maintenance helps prevent loosening and ensures a secure fit.

Implementing these maintenance methods can contribute to the longevity and optimal performance of kingpin bearings, promoting safer and more efficient vehicle operation.

Replacement Procedures

The kingpin bearing replacement procedure is a critical aspect of maintaining a vehicle’s steering system. The need for replacement typically arises when signs of wear, such as increased play in the steering, unusual noises, or uneven tire wear, become evident during routine inspections. To begin the replacement, the vehicle must be securely lifted and supported, and the wheel removed to access the kingpin assembly. The next steps involve disassembling the components connected to the kingpin, such as the tie rod and steering knuckle. Careful attention is required during disassembly to avoid damage to surrounding parts. Once the kingpin assembly is exposed, the old bearing is removed, and the area is thoroughly cleaned. Installing the new kingpin bearing involves precise alignment and secure fastening. After reassembling the components, it’s crucial to conduct a thorough inspection, check for proper alignment, and perform a test drive to ensure the steering system functions smoothly. Adhering to manufacturer specifications and torque values throughout the process is essential for a successful and reliable kingpin bearing replacement. Regular monitoring and timely replacements contribute to the longevity and optimal performance of the entire steering system.

Kingpin Bearings in Different Vehicles

The differences between kingpin bearings in various vehicles, such as passenger cars and commercial vehicles, primarily lie in their design and load-bearing capacities. In passenger cars, kingpin bearings commonly feature ball bearings, emphasizing reduced friction for smoother steering and improved handling in diverse driving conditions. These bearings are designed to handle the relatively lower loads associated with regular commuting. In contrast, commercial vehicles, including trucks and buses, often employ more robust tapered roller bearings. Tapered roller bearings offer greater load-bearing capabilities, making them suitable for the heavier loads and demanding conditions that commercial vehicles encounter. The choice of kingpin bearing type is influenced by the specific requirements of each vehicle category, emphasizing factors such as load capacity, durability, and the expected operating conditions to ensure optimal steering performance and longevity.

Environmental Impact

The environmental impact of kingpin bearings is influenced by both manufacturing practices and energy efficiency considerations. Sustainable manufacturing practices play a vital role in mitigating the environmental footprint of these components. Implementing eco-friendly materials, recycling initiatives, and reducing waste during the manufacturing process contribute to a more sustainable production cycle. Additionally, energy-efficient manufacturing techniques and technologies further minimize the overall environmental impact. Efficient use of resources, such as raw materials and energy, helps reduce greenhouse gas emissions associated with manufacturing. Furthermore, advancements in material science and lubrication technologies aim to enhance the longevity of kingpin bearings, reducing the frequency of replacements and minimizing the associated waste. By prioritizing sustainable manufacturing practices and energy efficiency, the automotive industry can contribute to a more eco-conscious approach, aligning with global efforts to reduce environmental impacts and promote a greener future.

Conclusion

In conclusion, kingpin bearings are integral to a vehicle’s steering and suspension systems, impacting maneuverability, control, and overall safety. Their historical evolution, diverse types, and critical role in handling necessitate proper maintenance to prevent issues like wear, corrosion, and misalignment. Replacement procedures and distinctions between bearings in different vehicles highlight the importance of tailored care. The environmental impact underscores the need for sustainable manufacturing practices. Understanding and maintaining kingpin bearings not only ensures optimal vehicle performance but also aligns with eco-conscious initiatives, promoting a safer, more efficient, and environmentally responsible automotive future.

References

- 1.”King Pin Seals & Bearings| Meritor_NA” from Meritor Parts Xpress;

- 2. “Kingpin” from Boca Bearings;

- 3. “King Pin Bearing” from O’Reilly Auto Parts.