Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Symphony of Silence: Noise Reduction in Linear Bearings

Introduction

Linear bearings play a pivotal role in noise reduction within mechanical systems. By providing smooth and precise motion along a linear path, these bearings minimize friction and vibration, consequently reducing operational noise. This is especially crucial in applications where noise control is paramount, such as in manufacturing machinery, robotics, or medical equipment. The design and material selection of linear bearings contribute to their effectiveness in dampening sound, ensuring quieter operation and enhancing the overall user experience. Incorporating advanced linear bearing technology not only improves performance but also aligns with the growing emphasis on creating quieter and more efficient mechanical systems across various industries.

Understanding the Impact of Noise

The impact of noise extends beyond mere auditory disturbance, influencing various aspects of human well-being and performance. Excessive noise levels can lead to stress, sleep disturbances, and impaired cognitive function, affecting productivity and overall health. In industrial settings, noise can contribute to occupational hazards, leading to hearing loss and reduced concentration. Additionally, in urban environments, persistent noise pollution is associated with adverse effects on cardiovascular health and quality of life. Recognizing and mitigating the impact of noise is crucial for creating healthier, more comfortable living and working environments, fostering improved concentration, communication, and overall human performance.

Noise-Sensitive Industries

Noise-sensitive industries prioritize quiet and controlled environments due to the potential negative impacts of noise on their processes, products, or occupants. The healthcare sector, including hospitals and laboratories, demands low noise levels to facilitate patient recovery and maintain precise experimental conditions. Similarly, the semiconductor and electronics manufacturing industry requires noise-free environments to ensure the precision of delicate processes. The aerospace industry, particularly in aircraft manufacturing and testing, emphasizes reduced noise for both worker comfort and to meet regulatory standards. In residential and commercial construction, minimizing noise is crucial for creating habitable spaces. Overall, these industries prioritize sound control to enhance productivity, product quality, and the well-being of individuals within and around their facilities.

Linear Bearings: The Silent Contributors

Unveiling the Basics: What Are Linear Bearings?

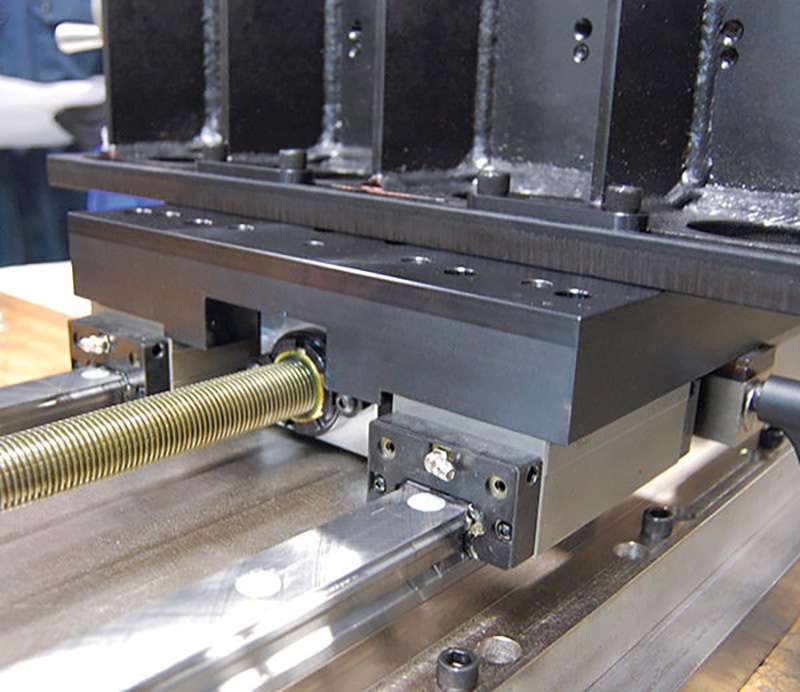

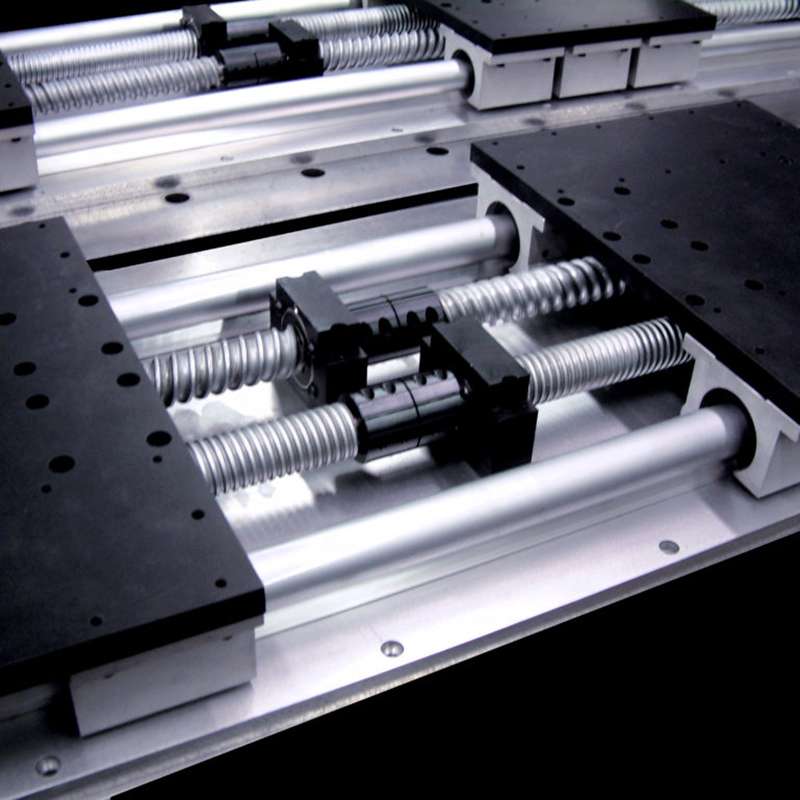

Linear bearings are fundamental components in mechanical systems, designed to facilitate smooth and precise motion along a linear axis. Typically incorporating ball or roller elements, these bearings minimize friction, enabling efficient movement in various applications like manufacturing machinery, automation, and medical devices. They ensure accurate positioning while supporting loads. Linear bearings are crucial for translating rotary motion into linear motion, playing a vital role in diverse industries where precision and reliability are paramount.

A Brief Overview for the Uninitiated The Evolution of Quiet Precision: Advancements in Linear Bearings

The evolution of linear bearings has witnessed a remarkable journey marked by advancements in quiet precision. Initially, these bearings were basic components ensuring linear motion with moderate precision. However, with technological strides, the focus shifted towards reducing noise levels in mechanical systems. Modern linear bearings employ innovative designs and materials, such as advanced polymers and ceramic elements, to minimize friction and vibration, resulting in quieter operation. These developments cater to the growing demand for noise reduction in industries like manufacturing, robotics, and healthcare. The evolution of linear bearings aligns with a broader trend in engineering, where the pursuit of precision is coupled with a commitment to creating quieter, more efficient, and user-friendly mechanical systems across diverse applications. This quiet precision not only enhances performance but also underscores the role of technological progress in fostering more sophisticated and harmonious interactions between machinery and their environments.

Materials and Design Innovations Leading to Noise Reduction

The pursuit of quieter and more efficient mechanical systems has driven significant materials and design innovations in the realm of linear bearings. Traditional metallic bearings have given way to advanced materials like polymers, ceramics, and hybrid composites. These materials not only enhance the load-bearing capacity and durability of linear bearings but also exhibit superior noise-dampening characteristics, reducing friction-induced sounds. Innovations in cage designs and surface treatments further contribute to smoother motion and decreased vibrations, leading to a substantial reduction in overall noise levels. Concurrently, precision engineering, facilitated by technologies like computer-aided design (CAD), allows for intricate, optimized structures that elevate the performance of linear bearings while prioritizing a quieter operational environment. These advancements underscore a commitment to noise reduction, making linear bearings pivotal components in creating machinery that aligns with the evolving standards of both efficiency and acoustics.

Case Studies: Implementing Silent Solutions

Hospital Innovations: How Linear Bearings Enhance Medical Equipment

Linear bearings play a crucial role in enhancing medical equipment, contributing to the innovative landscape within hospitals.

Precision Motion: Linear bearings facilitate precise linear motion in various medical devices, ensuring accurate positioning and movement critical for diagnostic equipment, robotic-assisted surgeries, and patient care systems.

Quiet Operation: Utilizing advanced materials and design, linear bearings contribute to quieter operation, a crucial factor in maintaining a conducive and low-stress environment in healthcare settings, where noise reduction is paramount.

Durability and Reliability: The robust construction of linear bearings ensures durability and reliability in medical equipment, promoting longevity and minimizing the need for frequent maintenance, essential for the uninterrupted functioning of critical healthcare machinery.

Patient Comfort: Linear bearings, through their smooth and controlled motion, enhance the overall patient experience by providing comfortable and gentle movements in various applications, such as adjustable beds, imaging tables, and rehabilitation devices.

Quieting the Home: Linear Bearings in Everyday Residential Applications

In everyday residential applications, linear bearings contribute to creating quieter and more efficient living spaces, addressing the need for comfort and convenience.

Furniture and Appliances: Linear bearings are employed in various furniture and appliance mechanisms, such as drawers, sliding doors, and retractable components, ensuring smooth and noise-free operation in everyday household items.

Home Automation Systems: Linear bearings play a key role in home automation systems, providing quiet and precise motion for applications like smart curtains, motorized blinds, and sliding door mechanisms, enhancing the overall experience of automated home environments.

Exercise Equipment: In home gym equipment, linear bearings enable smooth and quiet motion in features like adjustable seats, sliding components, and resistance systems, contributing to a more pleasant and less disruptive exercise experience.

Adjustable Furniture: Linear bearings are utilized in adjustable furniture like ergonomic chairs and height-adjustable desks, offering seamless adjustments without generating unnecessary noise, contributing to a comfortable and productive home environment.

Sustainable Silence: Eco-Friendly Linear Bearings

Eco-Conscious Manufacturing: The Environmental Impact of Linear Bearings

Eco-conscious manufacturing has shifted attention to the environmental impact of components like linear bearings. As vital elements in various mechanical systems, linear bearings influence sustainability through material choices, energy efficiency, and overall product lifecycle. This paradigm emphasizes the need for materials with reduced ecological footprints, efficient production processes, and bearings that contribute to energy savings through minimized friction. The exploration of environmentally friendly alternatives and the implementation of eco-design principles in linear bearing manufacturing signify a commitment to mitigating environmental impact, aligning with the broader global endeavor toward more sustainable industrial practices.

Linear bearing noise reduction and industrial green initiatives

Sustainable Materials: Linear bearings designed for noise reduction often incorporate sustainable materials, such as recycled plastics or bio-based composites, aligning with industrial green initiatives to reduce environmental impact and promote responsible material usage.

Energy Efficiency: Advanced designs in noise-reducing linear bearings contribute to improved energy efficiency by minimizing friction and vibrations, reducing the overall power consumption of machinery, and supporting industrial efforts to enhance energy sustainability.

Longevity and Reduced Waste: Noise-reducing linear bearings, with their emphasis on smoother operation and durability, contribute to longer equipment lifespans, reducing the frequency of replacements and minimizing waste, in line with industrial green initiatives aiming for extended product life cycles.

Optimized Production Processes: Implementing noise reduction strategies in linear bearing manufacturing often involves optimizing production processes, incorporating lean principles to reduce waste, energy consumption, and emissions, thereby supporting industrial green initiatives for more eco-friendly manufacturing practices.

Overcoming Challenges in Noise Reduction

Striking the Balance: Meeting Performance Standards Amidst Reduced Noise

Material Selection: Choose durable and wear-resistant materials for silent linear bearings, considering factors such as load capacity, environmental conditions, and the specific application requirements to ensure longevity and sustained performance.

Surface Treatments: Implement effective surface treatments, such as coatings or finishes, to enhance the wear resistance of critical components, protecting against corrosion and reducing friction for prolonged durability in silent linear bearings.

Lubrication Strategies: Develop and apply appropriate lubrication strategies to minimize wear and tear, ensuring that silent linear bearings maintain their optimal performance over an extended period without succumbing to lubrication-related issues.

Sealing Solutions: Employ reliable sealing mechanisms to protect silent linear bearings from contaminants, moisture, and debris, preventing premature wear and corrosion that could compromise their durability and contribute to increased noise levels.

Rigorous Testing Protocols: Implement thorough testing protocols during the design and manufacturing stages to assess the durability of silent linear bearings under various conditions, ensuring they meet or exceed industry standards for longevity and can withstand the challenges of prolonged use in diverse applications.

The Future Sounds Silent: Innovations on the Horizon

Emerging Technologies: What's Next in Noise Reduction with Linear Bearings

Smart Lubrication Systems: The integration of smart lubrication systems, utilizing sensors and real-time data analysis, will enable more precise and efficient lubrication in linear bearings, reducing friction and noise while optimizing performance.

Advanced Materials: Ongoing advancements in materials science may introduce novel materials with superior noise-dampening properties, allowing for the development of next-generation silent linear bearings that excel in both performance and environmental sustainability.

Machine Learning for Design Optimization: The application of machine learning algorithms in the design process can lead to optimized configurations of linear bearings, tailored for specific applications, resulting in improved noise reduction without compromising functionality.

Vibration Control Technologies: Innovations in vibration control technologies, including active damping systems, could be integrated into linear bearings to actively counteract vibrations and further reduce noise in real-time, particularly in high-precision and high-speed applications.

Nano-scale Engineering: Exploring nano-scale engineering for smoother surfaces and reduced friction at the microscopic level could offer new possibilities for noise reduction in linear bearings, contributing to quieter operation and enhanced overall system efficiency.

Conclusion

As industries continue to evolve, the symphony of silence orchestrated by advancements in linear bearing technology becomes increasingly pronounced. Embracing silence as a standard in industry is not merely a technological feat but a profound commitment to the well-being of individuals and the environment. The quiet revolution is not ephemeral; it is here to stay, and linear bearings, as the unsung heroes, stand at the forefront, ensuring that the machinery of progress operates harmoniously and silently.

References

1.”Linear-motion bearing” from Wikipedia;

2. “Linear Bearings Quality Standard” from ISO.org;

3. “Linear Guides” from NSK.