Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

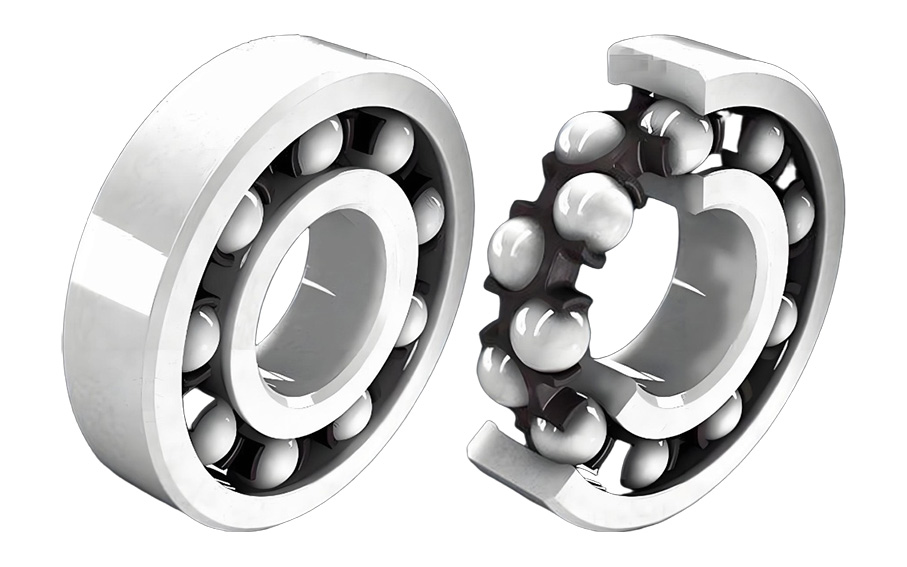

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Medical device bearing overview

Medical Equipment Bearings are special types of bearings used in medical equipment and instruments, usually having the following characteristics and requirements:

peculiarity

1.High precision

Bearings in medical devices require extremely high precision to ensure smooth operation and accurate results. For example, the bearing tolerance in equipment such as CT machines, MRI machines and dental drills is very small.

2.Low noise and vibration

The medical environment needs to be quiet and stable, so the bearing must have low noise and low vibration characteristics.

3.Corrosion resistance

Medical equipment often requires frequent cleaning and disinfection, and bearing materials need to be corrosion resistant and able to withstand chemicals or high temperature sterilization.

4.Long life and high reliability

Medical equipment must be reliable and durable to reduce maintenance needs and ensure patient safety.

5.No pollution (cleanliness)

Medical equipment has high requirements for cleanliness and hygiene, and bearings cannot release any contaminants, such as grease or particles, during operation.

Common materials

1.Stainless steel bearings (such as 440C, 316 stainless steel) : excellent corrosion resistance, suitable for humid heat or disinfection environment.

2.Ceramic bearings: with higher wear resistance, corrosion resistance and non-magnetic, suitable for sensitive environments.

3. Hybrid ceramic bearings: Combine ceramic balls and stainless steel rings, combining the advantages of ceramic and metal.

Types of bearings for medical devices

Medical equipment bearings come in various types depending on their specific applications and operational requirements. Here’s an overview of the main types of bearings used in medical equipment:

1. Ball Bearings

- Description: Bearings with balls as rolling elements, designed to handle radial and axial loads.

- Applications:

- Centrifuges

- Diagnostic imaging devices (e.g., CT scanners, MRI machines)

- High-speed dental drills

- Materials: Stainless steel, ceramic, or hybrid (ceramic balls with steel races).

- Features: High precision, low noise, corrosion-resistant, and capable of high-speed operation.

2. Roller Bearings

- Description: Bearings that use cylindrical, spherical, or tapered rollers to distribute loads over a larger area.

- Applications:

- Hospital beds and patient lifts

- Imaging equipment with heavy loads

- Robotic surgical systems

- Materials: Stainless steel or other durable alloys.

- Features: High load capacity and durability.

3. Miniature Bearings

- Description: Compact ball bearings designed for small medical devices.

- Applications:

- Surgical tools

- Hand-held medical devices

- Precision instruments like microscopes

- Materials: Stainless steel or hybrid ceramic.

- Features: Ultra-high precision, low friction, and small size for tight spaces.

4. Angular Contact Bearings

- Description: Ball bearings that support combined radial and axial loads, with higher thrust capacity in one direction.

- Applications:

- Surgical robots

- High-speed centrifuges

- Dental turbines

- Materials: Stainless steel or ceramic.

- Features: High speed and load capacity, precision performance.

5. Thrust Bearings

- Description: Bearings designed to handle axial loads.

- Applications:

- Operating tables

- Rotational parts of diagnostic devices

- Pump systems for medical fluids

- Materials: Stainless steel.

- Features: Durable and reliable for axial load applications.

6. Needle Roller Bearings

- Description: Bearings with thin, cylindrical rollers for high load capacity in a compact design.

- Applications:

- Portable diagnostic tools

- Mobility aids (e.g., wheelchairs)

- Patient transport equipment

- Materials: Stainless steel.

- Features: Compact and high load capacity.

7. Ceramic Bearings

- Description: Bearings made entirely or partially from ceramic materials.

- Applications:

- MRI machines (non-magnetic environments)

- High-speed surgical drills

- Materials: Zirconia or silicon nitride ceramics.

- Features: Lightweight, corrosion-resistant, non-magnetic, and suitable for extreme conditions.

8. Magnetic Bearings

- Description: Bearings that use magnetic fields to support rotating components without physical contact.

- Applications:

- High-tech diagnostic equipment (e.g., MRI)

- Pumps used in heart-lung machines

- Materials: Magnetic materials with precise engineering.

- Features: Frictionless, silent operation, and suitable for sensitive environments.

9. Spherical Bearings

- Description: Bearings with spherical inner surfaces to allow angular rotation.

- Applications:

- Robotic arms in surgery

- Prosthetic devices

- Materials: Stainless steel or polymer composites.

- Features: Flexibility for multi-directional movement.

10. Plain Bearings

- Description: Simplified bearings with no rolling elements, used for sliding motion.

- Applications:

- Adjustable hospital beds

- Medical examination chairs

- Infusion pumps

- Materials: PTFE, bronze, or stainless steel.

- Features: Cost-effective, quiet, and maintenance-free.

Bearings for Medical Equipment Durability That Drives Trust

1. Introduction to Bearings in Medical Equipment

Importance of Bearings in Medical Devices

Bearings are the unsung heroes of medical equipment, quietly enabling the smooth operation of critical devices. From diagnostic machines to surgical robots, they ensure components move with precision and reliability. Without robust bearings, healthcare machinery would falter, potentially compromising patient outcomes.

How Durability Impacts Performance and Trust

In the medical field, reliability isn’t just a convenience—it’s a necessity. Durable bearings guarantee uninterrupted performance, reducing the risk of equipment failures during vital procedures. When procurement professionals invest in long-lasting components, they’re also investing in the trust of healthcare providers and patients alike

Role of Bearings in Critical Healthcare Applications

Bearings are integral to the function of diagnostic, therapeutic, and monitoring equipment. Whether it’s facilitating high-speed rotations in a centrifuge or enabling the precision of a robotic arm, these components are at the heart of modern medical advancements. Their performance can literally be the difference between life and death.

2. Key Components of Durable Bearings

Materials Used in Durable Bearings

The backbone of any durable bearing lies in its material composition. Stainless steel, ceramics, and hybrid materials are commonly chosen for their strength and resistance to wear. These materials endure the rigors of medical environments while maintaining exceptional performance.

Engineering for Wear and Tear Resistance

Wear and tear are inevitable, but engineering innovations like heat-treated surfaces and precision machining can significantly extend a bearing’s lifespan. These techniques reduce friction, enhance load distribution, and ensure consistent operation over time. Longevity in such components translates to fewer replacements and more reliable devices.

Importance of Corrosion Resistance in Medical Environments

Medical bearings must withstand frequent exposure to disinfectants, sterilization processes, and bodily fluids. Corrosion resistance is critical to maintaining their integrity and function. Bearings treated with special coatings or crafted from corrosion-resistant materials thrive in these challenging conditions.

3. Why Durability Matters in Medical Bearings

Ensuring Patient Safety Through Reliable Equipment

Patient safety depends on the reliability of medical devices, and bearings play a pivotal role in this. A failure in a critical bearing could lead to diagnostic errors or interruptions in surgical procedures. Durable bearings are a safeguard against such catastrophic outcomes.

Minimizing Downtime in Healthcare Operations

Downtime isn’t just an inconvenience—it’s a disruption to patient care and facility operations. Durable bearings reduce the frequency of maintenance and repairs, keeping medical devices operational when they’re needed most. This continuity directly benefits healthcare professionals and their patients.

Long-Term Cost Savings for Medical Facilities

While high-quality bearings may have a higher upfront cost, their longevity delivers significant savings over time. Fewer replacements and reduced maintenance translate to lower operating expenses. For procurement professionals, this is a smart investment that pays dividends.

4. Applications of Bearings in Medical Equipment

Diagnostic Equipment Like MRI and CT Machines

MRI and CT machines rely on bearings for the precise movement of internal components. High-speed rotations and sensitive imaging functions demand exceptional durability and precision. Bearings in these devices are designed to handle rigorous use without compromising accuracy.

Surgical Tools and Robotic Systems

Modern surgical tools and robots require bearings that offer smooth and precise movements. These devices operate in sterile environments, making corrosion resistance and low friction crucial. Durable bearings ensure the reliability and dexterity surgeons need during complex procedures.

Laboratory Devices and Patient Care Equipment

Laboratory centrifuges, infusion pumps, and patient beds all depend on bearings for functionality. These components must withstand repeated use while maintaining smooth operation. Their durability is essential for supporting both diagnostic and therapeutic processes.

5. Precision Engineering for Medical Bearings

Tight Tolerances for Medical-Grade Bearings

Precision engineering ensures that medical bearings operate within incredibly tight tolerances. This level of accuracy reduces wear and optimizes performance. It’s particularly vital for applications where even the slightest deviation can lead to errors.

Balancing Speed and Load Capabilities

Medical bearings often need to support both high-speed rotations and significant loads. Engineers carefully balance these requirements through advanced design and material selection. This balance is key to achieving optimal functionality in demanding environments.

Customization for Specific Medical Applications

Every medical device is unique, and bearings must often be tailored to fit these specific needs. From size adjustments to specialized coatings, customization ensures that bearings perform flawlessly in their intended applications. Collaboration between manufacturers and procurement teams is essential for achieving these results.

6. Corrosion Resistance and Its Importance

Effects of Sterilization and Cleaning on Bearings

Frequent sterilization cycles can take a toll on bearings, causing wear or corrosion over time. High-quality materials and protective coatings help bearings withstand these rigorous cleaning processes. This ensures consistent performance and compliance with hygiene standards.

Coatings That Protect Against Chemical Exposure

Specialized coatings, such as PVD or PTFE, provide an extra layer of protection against chemicals used in cleaning and disinfection. These coatings enhance the lifespan of bearings while maintaining their smooth operation. Choosing the right coating depends on the specific application and environment.

Case Studies on Corrosion-Resistant Bearings

Real-world examples highlight the importance of corrosion-resistant bearings. In one case, a hospital reduced maintenance costs significantly by switching to bearings with advanced anti-corrosion coatings. These success stories demonstrate the value of investing in durable solutions.

In SUMMARY:

Durable bearings are essential in medical equipment, ensuring reliability, safety, and performance. By using high-quality materials, precision engineering, and advanced coatings, they help minimize downtime, reduce costs, and build trust in critical healthcare applications. From diagnostic machines to surgical tools, their role in patient safety and operational efficiency is indispensable, making them a key consideration for procurement professionals in the medical industry.

Very great post. I just stumbled upon your weblog and wished to say that I’ve truly loved browsing your blog posts. After all I will be subscribing in your feed and I’m hoping you write again very soon!