Categories

How plain bearings improve system efficiency

Table of Contents

Behind the scenes of a mechanical system, plain bearings silently support the entire operation with their ingenious design and efficient lubrication strategies. In this article, we will take a closer look at how plain bearings can greatly reduce friction through these clever lubrication strategies and surface designs, thereby increasing system efficiency.

——Sleeves And Bushings

The sleeve and bushing are one of the core construction elements of a plain bearing. The sleeve is usually a cylindrical part, while the bushing is an external part that fits over the sleeve. The gap between them is usually tiny to ensure proper relative motion.

- Function

- Support and Positioning: The sleeve provides support and positioning of the shaft to ensure that the movement of the shaft is accurate and stable.

- Load Distribution: The sleeve and bushings share the load on the shaft, ensuring that the load on the shaft is evenly distributed.

——Lubricant Film

The lubricant film is a thin film formed by the lubricant between the sleeve and the bushings. This oil film reduces the contact of direct metal surfaces during plain, thus reducing friction and wear.

- Function

- Friction Reduction: The presence of the oil film effectively reduces the friction between the sleeve and the bushings and increases the efficiency of the bearing.

- Heat Dispersion: The oil film helps to disperse the heat generated by friction during movement, preventing the bearing from overheating.

—— Lubrication System

The lubrication system consists of supply and drain channels to ensure that the lubricant can circulate inside the bearing. This is usually powered by an external lubrication device or system.

- Function

- Oil supply: Introduces lubricant into the space between the sleeve and bushings to form a lubricant film.

- Oil Drain: Drain the lubricant that has been used to maintain the cleanliness and performance of the lubricant.

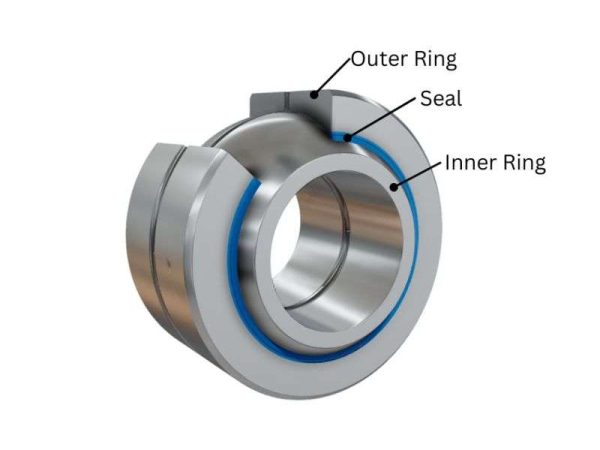

—— Seals

- Function

- Dust and waterproof: The seals effectively prevent the entry of dust, moisture and other external contaminants, keeping the bearings clean and reliable.

—— Fixed Components

Plain bearings usually need to be integrated with other parts of the mechanical system and may therefore include some fixed parts such as a base or bracket.

- Function

- Mechanical Integration: In combination with other components of the mechanical system, it ensures that the bearing is correctly positioned and secured throughout the system.

Subtleties In The Design Of plain bearings Surfaces

The surface design of plain bearings is one of the keys to their superior performance. Through the use of advanced surface treatment technologies, plain bearings can achieve significant achievements in terms of reduced friction, improved wear resistance and longer service life.

——Polishing and grinding technology

The surfaces of plain bearings are treated with highly refined polishing and grinding technology to ensure smoothness and uniformity of the surfaces. This is to reduce the roughness of the direct metal surface and thus minimize the occurrence of friction.

Function:

- Friction Reduction: Smooth surfaces effectively reduce friction and increase the efficiency of the bearing.

- Uniform oil film distribution: Smooth surfaces help the oil film to be uniformly distributed with in the bearing, enhancing lubrication.

——Application Of Surface Coatings

Some advanced plain bearings utilize surface coating techniques such as applying solid lubricants or employing coating-reinforced materials. These surface coatings provide additional lubrication and protection by replacing conventional lubricants to some extent.

Function:

- Lubricant Replacement: Surface coatings can provide a degree of replacement for conventional lubricants, reducing reliance on external lubrication sources.

- Enhanced Wear Resistance: Coatings can enhance the wear resistance of bearings and extend service life.

——Design Of Surface Microstructures

Some plain bearing surfaces are designed with microstructures, such as microholes or microgrooves. This design helps to form tiny lubricant pools in the bearing movement and improves the lubrication effect.

Function:

- Formation of micro oil film: The microstructure helps to form a tiny lubricant film on the surface, which further reduces friction.

- Improved lubrication: The microstructure design improves the distribution of lubricant on the surface, increasing the efficiency of the overall lubrication system.

—— Introduction Of Wear-resistant Alloys

Surface design can also be improved by employing special wear-resistant alloys. These alloys provide superior wear resistance against the effects of friction and abrasion.

Function:

- Resistance to friction and wear: Wear-resistant alloys provide an additional layer of protection against friction and wear caused by the external environment and loads.

——Optimization Of Material Selection

The surface design of plain bearings is also closely related to the selected material. A rational choice of material ensures that the surface maintains its stability and performance under different operating conditions.

Function:

- Adaptation to diverse operating conditions: Optimized selection of materials helps to ensure that the bearings maintain stable performance under diverse operating conditions.

- Automotive Industry

Plain bearings have a wide range of applications in the automotive industry. They are used in a variety of parts such as engines, transmissions, wheel hubs, and suspension systems. In engines, plain bearings support the rotation of crankshafts and camshafts, reducing friction between components and improving engine efficiency. Sliding bearings in wheel hubs and suspension systems provide a smoother ride.

- Aerospace

In aerospace, plain bearings are widely used in aircraft engines, landing gear and flight control systems. Their light weight, high strength and low friction properties make them ideal for improving aircraft performance and reliability.

- Industrial Manufacturing

Plain bearings are used in a wide range of industrial manufacturing applications, including machine tools, wind turbines, and conveyor belt systems. They ensure the smooth operation of mechanical equipment, reduce wear and tear on moving parts, and increase the life of the equipment.

- Energy field

In the energy sector, plain bearings are used in power generation equipment such as wind turbines and hydroelectric generators. Their efficient lubrication and wear resistance characteristics help to improve the performance of power generation equipment.

- Railway Transportation

In railroad and subway systems, plain bearings are used in critical parts of trains such as wheels and bogies. They provide support and guidance functions, reduce friction between the wheels and the railroad tracks, and improve the operating efficiency of the train.

- Marine Engineering

Plain bearings are also used in marine engineering, especially in the propulsion system, rudder, mooring system and other key parts of ships. Its corrosion and wear resistance make it adaptable to the complex conditions of the marine environment.

- Military Application

In the military field, plain bearings are widely used in key parts of military equipment such as tanks, airplanes and ships. They play a key role in providing support, minimizing friction, and reducing noise to ensure the efficiency and reliability of military systems.

- Home appliances and consumer goods

Plain bearings also have practical applications in home appliances and consumer goods, such as electric fans and tumble dryers. They ensure the smooth operation of home appliances and provide convenience in daily life.

Conclusion

In the design and operation of plain bearings, the use of clever lubrication strategies and well-designed surfaces are at the heart of improving the efficiency of the system. Through the combined application of these strategies, plain bearings are able to minimize friction and increase the efficiency of the system. This not only helps to save energy, reduce wear and tear, and extend the life of the bearing and the overall system, but also improves the overall performance of the system. In an ever-evolving technological environment, further research and innovation will continue to drive the efficiency of plain bearings, providing more reliable and efficient solutions for a wide range of industrial applications.