Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

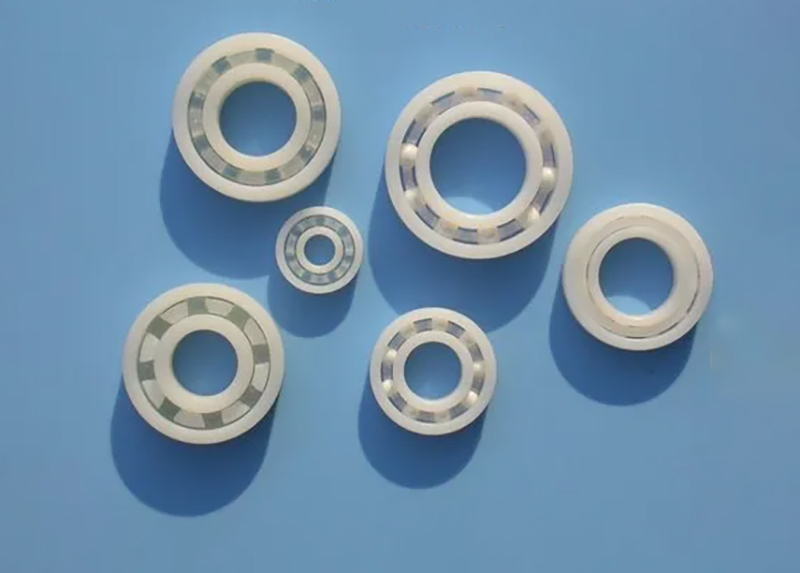

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Advanced Additives and Reinforcements for Plastic Bearings: Enhancing Durability and Strength

Introduction

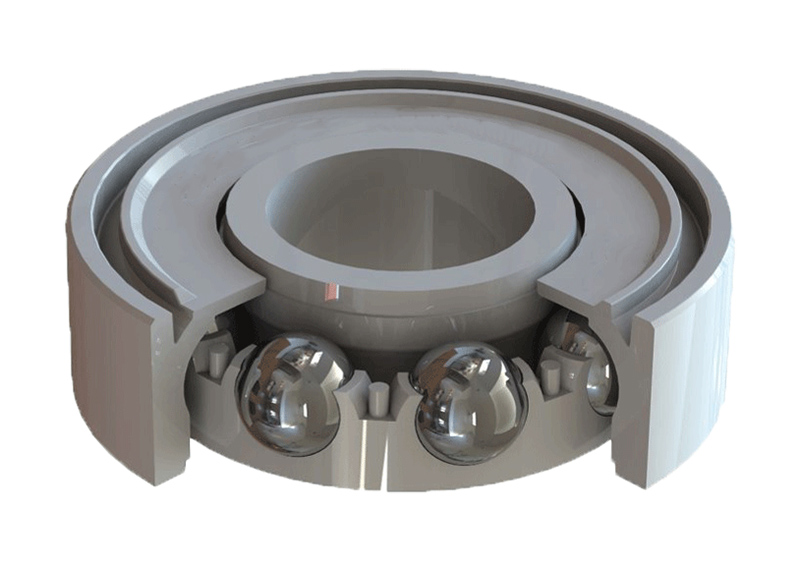

Brief overview of plastic bearings

Plastic bearings are engineered from high-performance polymers such as nylon, polyethylene, or PTFE, offering exceptional resistance to corrosion, chemicals, and moisture. One significant advantage lies in their ability to operate without the need for lubrication, reducing maintenance requirements and enhancing operational efficiency. Additionally, plastic bearings are lightweight, contributing to energy savings and facilitating easier installation. Their versatility extends to diverse applications, including automotive, aerospace, medical devices, and food processing equipment, where their non-conductive properties make them particularly valuable. In summary, plastic bearings embody a modern solution that combines durability, reliability, and adaptability to meet the demands of contemporary industrial settings.

Importance of durability, strength, and wear resistance in plastic bearings

Plastic bearings are engineered to withstand demanding operating conditions, including high loads, extreme temperatures, and corrosive environments, without compromising performance. This durability ensures prolonged service life and reduces the need for frequent replacements, leading to cost savings and operational continuity. Furthermore, their inherent strength enables them to withstand heavy loads while maintaining dimensional stability, crucial for maintaining precision in machinery and equipment. Additionally, exceptional wear resistance minimizes friction and abrasion, preserving the integrity of the bearing and associated components, thereby enhancing overall efficiency and reliability. In essence, the robust combination of durability, strength, and wear resistance underscores the indispensable role of plastic bearings in modern industrial systems.

Understanding Plastic Bearings

Plastic bearings, characterized by their composition of high-performance polymers like nylon, polyethylene, or PTFE, serve as integral components in various industrial applications. These bearings boast exceptional properties such as corrosion resistance, chemical inertness, and self-lubrication, making them ideal for environments where traditional metal bearings may falter. Additionally, their lightweight nature facilitates easier installation and contributes to energy efficiency. However, traditional plastic bearings have encountered challenges, particularly in terms of load-bearing capacity and dimensional stability under extreme conditions. High loads can lead to deformation or premature wear, impacting the overall performance and longevity of the bearing. Moreover, temperature fluctuations and exposure to harsh chemicals may degrade the material over time, compromising its structural integrity. These challenges necessitate continuous innovation in material science and bearing design to enhance load-bearing capabilities, dimensional stability, and overall reliability, ensuring plastic bearings remain a viable solution across diverse industrial sectors.

Importance of Durability and Strength

The durability and strength of plastic bearings play a pivotal role in dictating their overall performance and longevity, particularly in demanding industrial applications. These bearings must withstand rigorous operating conditions, including high loads, extreme temperatures, and exposure to corrosive substances, without compromising their functionality. Enhanced durability ensures that plastic bearings can withstand prolonged use without succumbing to wear or degradation, thereby minimizing the frequency of maintenance and replacement cycles. Moreover, durability contributes to the reliability of the bearing system, reducing the risk of unexpected downtime and associated costs.

Factors such as friction, temperature fluctuations, and chemical exposure can contribute to wear and degradation over time, highlighting the importance of robust materials and design strategies. Plastic bearings are often subject to friction and abrasion during operation, particularly in high-speed or heavy-duty applications, which can gradually erode their surface and compromise performance. Furthermore, exposure to fluctuating temperatures or aggressive chemicals can accelerate material degradation, leading to reduced bearing lifespan and potential safety hazards.

In demanding applications where reliability is paramount, such as automotive manufacturing, aerospace, or heavy machinery, the need for plastic bearings with enhanced durability and strength becomes even more critical. These industries rely on bearings that can withstand intense operational demands while maintaining optimal performance, underscoring the necessity for continuous advancements in material science and bearing technology to meet these challenges effectively. By addressing factors leading to wear and degradation and emphasizing the importance of durability and strength, manufacturers can develop plastic bearings capable of enduring the rigors of demanding industrial environments, ensuring reliable and efficient operation in critical applications.

Overview of Advanced Additives

Definition and purpose of additives in plastic bearings

Additives play a crucial role in enhancing the performance and functionality of plastic bearings, serving as supplementary components incorporated into the base polymer matrix during manufacturing. These additives are diverse in nature, ranging from fillers and reinforcements to lubricants and stabilizers, each serving specific purposes tailored to the requirements of the application. Fillers, such as glass or carbon fibers, are commonly used to reinforce the polymer matrix, improving mechanical strength and wear resistance. Lubricants, like PTFE or silicone, are added to reduce friction and enhance self-lubricating properties, minimizing wear and extending the bearing’s lifespan. Stabilizers, including antioxidants and UV inhibitors, help mitigate degradation caused by environmental factors such as heat, light, and chemical exposure, preserving the integrity of the material over time. Additionally, additives can modify properties such as thermal conductivity, electrical insulation, or flame retardancy, further expanding the versatility of plastic bearings across diverse industrial settings. In essence, additives serve to tailor the performance characteristics of plastic bearings, ensuring optimal functionality, durability, and reliability in various applications.

Types of advanced additives used in bearing manufacturing

Lubricating additives are among the most prominent, offering solutions to mitigate friction and reduce wear between moving parts. These additives, such as PTFE (polytetrafluoroethylene) or graphite, form a lubricating film on the bearing surfaces, facilitating smoother motion and preventing metal-to-metal contact. Reinforcing additives, including glass or carbon fibers, are integrated into the polymer matrix to bolster mechanical strength and rigidity, enabling bearings to withstand higher loads and resist deformation. Moreover, wear-resistant additives, such as molybdenum disulfide or ceramic nanoparticles, are strategically incorporated to improve the bearing’s resistance to abrasion and prolong its service life. These additives form a protective barrier on the bearing surfaces, reducing frictional forces and minimizing surface damage even under demanding operating conditions. Through the integration of these advanced additives, bearing manufacturers can tailor the properties of plastic bearings to meet the specific requirements of diverse applications, ensuring optimal performance, durability, and reliability.

Reinforcements in Plastic Bearings

Introduction to reinforcement materials

These reinforcement materials are typically in the form of fibers or particles, such as glass, carbon, or aramid, which are incorporated into the polymer matrix during the manufacturing process. Glass fibers, for instance, are widely used due to their affordability and ability to significantly improve the stiffness and strength of plastic bearings. Carbon fibers, on the other hand, offer exceptional strength-to-weight ratio, making them suitable for applications requiring high-performance bearings with reduced weight. Aramid fibers, known for their excellent impact resistance and durability, are utilized in bearings subjected to dynamic loads or vibrations. By reinforcing the polymer matrix with these materials, manufacturers can tailor the properties of plastic bearings to meet the specific requirements of diverse industrial applications, ensuring optimal performance, reliability, and longevity.

Common reinforcement options for plastic bearings

Glass fibers, one of the most prevalent choices, effectively enhance the stiffness and mechanical properties of plastic bearings, thereby improving load-bearing capacity and resistance to deformation. By embedding glass fibers within the polymer matrix, manufacturers can create bearings capable of withstanding higher loads without succumbing to structural failure. Moreover, the incorporation of glass fibers helps to mitigate issues such as creep and fatigue, which are common concerns in bearings subjected to prolonged or repeated stress. This reinforcement option is particularly beneficial in applications where dimensional stability and precision are paramount, ensuring that the bearings maintain their integrity over extended periods of use.

Carbon fibers, renowned for their exceptional strength-to-weight ratio, provide unparalleled reinforcement, allowing for the creation of lightweight yet robust bearings suitable for demanding applications. Carbon fiber-reinforced plastic bearings offer superior mechanical performance, exhibiting high tensile strength and stiffness while remaining relatively lightweight. Additionally, carbon fiber reinforcement enhances the fatigue resistance of plastic bearings, reducing the risk of premature failure and prolonging the service life of the bearings in dynamic operating environments.

Aramid fibers, with their outstanding impact resistance and durability, offer a reliable solution for bearings subjected to dynamic loads or high-impact scenarios. Aramid fiber-reinforced plastic bearings exhibit excellent resistance to abrasion and wear, making them suitable for applications involving frequent or intense mechanical contact. Furthermore, aramid fibers contribute to the overall toughness of the bearing, enabling it to withstand sudden shocks or impacts without sustaining damage. This reinforcement option enhances the reliability and longevity of plastic bearings in rugged operating conditions.

Advanced Lubrication Solutions

Advanced lubrication additives for improved performance

Advanced lubrication additives play a crucial role in enhancing the performance and longevity of plastic bearings, offering solutions to mitigate friction and reduce wear between moving parts. Solid lubricants represent one category of these additives, with materials such as PTFE (polytetrafluoroethylene) and graphite being commonly used. These solid lubricants form a thin film on the bearing surfaces, providing a low-friction interface that reduces the risk of metal-to-metal contact and minimizes wear over time. Nanoparticle additives, another innovative lubrication solution, involve the incorporation of nanoparticles, such as molybdenum disulfide or tungsten disulfide, into the polymer matrix of the bearings. These nanoparticles exhibit unique lubricating properties at the nanoscale, effectively reducing friction and enhancing wear resistance even under extreme operating conditions.

Furthermore, self-lubricating materials represent a notable advancement in bearing technology, offering built-in lubrication mechanisms that eliminate the need for external lubricants. These materials, often based on polymers impregnated with solid lubricants or dispersed with microcapsules containing lubricating oils, continuously release lubricating agents during operation, ensuring smooth and reliable performance over extended periods.

Composite Bearings: Combining Additives and Reinforcements

Combining additives and reinforcements in plastic bearings offers a multitude of advantages, resulting in superior performance, durability, and reliability. By integrating reinforcing materials such as glass fibers, carbon fibers, or aramid fibers into the polymer matrix, manufacturers can enhance the mechanical strength, stiffness, and load-bearing capacity of the bearings, thereby reducing the risk of deformation and premature failure under heavy loads or harsh operating conditions. These reinforcement materials act as a structural backbone, reinforcing the polymer matrix and providing increased resistance to stress and impact. Additionally, the incorporation of lubricating additives such as PTFE, graphite, or nanoparticles improves the bearings’ friction-reducing properties, minimizing wear and extending their service life. These additives create a lubricating layer between moving surfaces, reducing frictional forces and preventing metal-to-metal contact, which in turn reduces the risk of wear and increases the longevity of the bearings.

Examples of composite materials used in bearing manufacturing include glass fiber-reinforced nylon bearings, which offer increased strength and stiffness for applications requiring high load-bearing capabilities, as well as carbon fiber-reinforced PTFE bearings, renowned for their low friction and excellent wear resistance in high-speed and high-temperature environments. These advanced composite materials combine the benefits of both reinforcements and lubricating additives, resulting in plastic bearings that excel in performance, longevity, and versatility across a wide range of industrial applications. By strategically combining additives and reinforcements, manufacturers can tailor the properties of plastic bearings to meet the specific requirements of diverse applications, ensuring optimal performance and reliability in demanding operating environments.

Conclusion

In conclusion, plastic bearings represent a modern solution for diverse industrial applications, offering exceptional durability, strength, and wear resistance. Through continuous innovation in material science and bearing design, manufacturers enhance load-bearing capabilities, dimensional stability, and overall reliability. Advanced additives, including lubricants and stabilizers, optimize performance, while reinforcements such as glass, carbon, or aramid fibers bolster mechanical properties. Combining these elements results in composite bearings that excel in performance and versatility, meeting the demands of demanding environments. As industries evolve, plastic bearings remain indispensable components, providing efficient and reliable operation while reducing maintenance costs and downtime, ultimately driving productivity and sustainability in modern industrial settings.

References

- 1.”What Factors Affect Bearing and Wear Resistance of High-Performance Plastic Components?” from Drake Plastics;

- 2. “Plastic & Composite Bearings, Bushings & Thrust Washers” from Boedeker Plastics;

- 3. “Structural plastic with reinforcement has enhanced properties” from Plastemart.