Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Key Role Of Railway Bearings: Comprehensive Analysis

Introduction

As an important part of the global transportation system, rail transportation is very important in terms of safety, efficiency, and reliability. Among the many components of the railway system, bearings are also key. The main function of bearings is to support mechanical rotating bodies and reduce friction during movement, thereby improving transportation efficiency and reducing energy consumption. In the railway system, the performance of bearings directly affects the operating safety and maintenance costs of trains. This article comprehensively analyzes multiple aspects of railway bearings. It deeply explores the types, characteristics, application scenarios, and advantages of railway bearings. It also discusses how the performance indicators of railway bearings affect the overall performance of the train.

Features Of Railway Bearings

➊ Due to the huge weight of trains and their cargo, railway bearings have high load capacity and can effectively support axial, radial, and moment loads.

➋ Railway bearings materials provide durability and long-term reliability.

➌ Railway bearings have low maintenance requirements, extending service life and reducing the need for frequent maintenance inspections.

➍ Railway bearings are often exposed to harsh environments and are therefore made of corrosion-resistant materials or coatings.

➎ On tracks running at high speeds. Railway bearings have the ability to absorb shock and withstand vibration.

➏ Railway bearings that operate efficiently at high speeds can reduce friction and heat generation.

➐ Railway bearings are designed to be energy-efficient, reduce friction, and improve rolling efficiency, reducing energy consumption and operating costs.

➑ Adaptable to different railway systems

These features together ensure that railway bearings can meet the stringent requirements of railway transportation and play a key role in the safety, efficiency, and reliability of train operation.

What Types Of Railway Bearings Are Used?

Railway bearings are specialized to meet the diverse needs of the railway industry. Each type of bearing offers unique benefits and is suited for specific applications within the railway system.

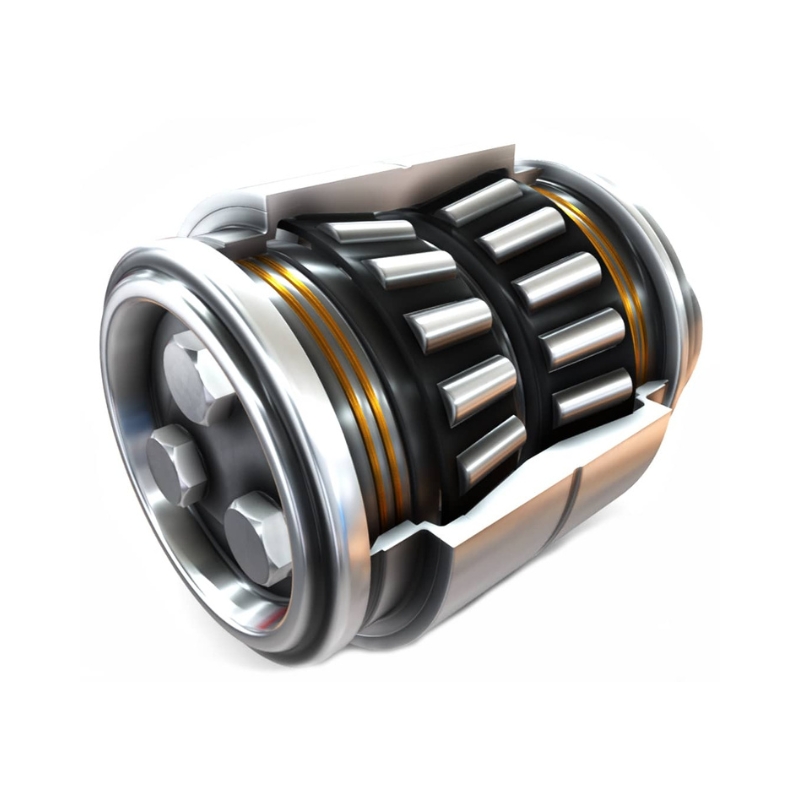

- Cylindrical Roller Bearings: are designed to handle high radial loads and moderate speeds. commonly used in gearbox applications and drive systems.

- Tapered Roller Bearings: the ability to handle combined heavy radial and axial loads. Extensively used in wheel axles, helps to ensure stability and alignment.

- Plain bearings are used in applications where low friction is necessary and where rotational speeds are not exceedingly high. Typically found in applications involving oscillatory movements or limited rotational motion such as bogie pivots.

- Magnetic bearings use magnetic forces to maintain a gap between the bearing and the shaft, eliminating direct contact. They are used in high-speed train applications, helping to reduce friction and increase energy efficiency.

- Deep Groove Ball Bearings: support both radial and light axial loads. They are commonly used in electric motors and auxiliary applications within trains where high speeds and low torque are typical.

- Angular Contact Ball Bearings: Designed to handle higher axial and radial loads, they are suited for the front and rear axles of trains—their ability to withstand load from both axes simultaneously.

- Are designed to handle high axial loads but minimal radial loads. They are used in the pivot and suspension areas of railway carriages.

Wheel bearings:

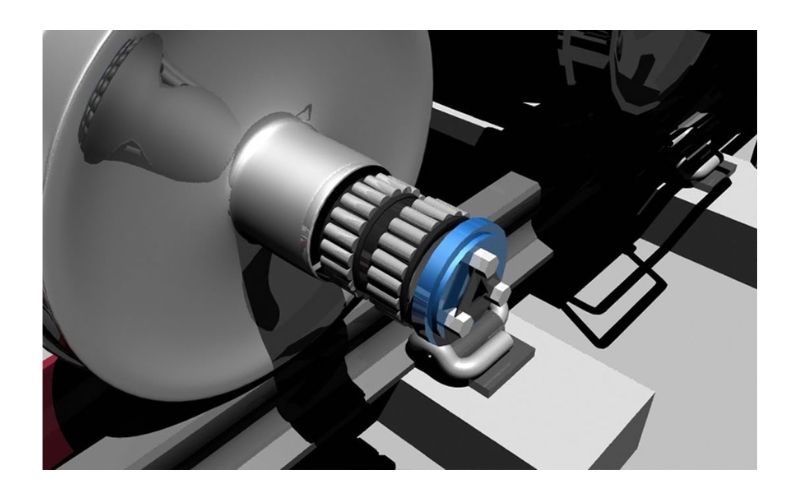

- Wheel bearings are critical to the safe and efficient operation of railway vehicles. They are specially designed to withstand the harsh conditions of rail transportation while supporting heavy loads, ensuring smooth operation of the wheels.

Fluid Bearings:

- Fluid bearings, which can be either hydrodynamic or hydrostatic, use a layer of fluid to support the bearing’s loads.

Why Roller Bearings Are Most Advantageous In Railway Applications

Structurally, roller bearings distribute loads over a larger surface area, improving their ability to withstand heavy and shock loads – a common requirement in dynamic rail environments. This distribution not only extends the service life of the bearings, but also improves the overall reliability of train operations. The cylindrical and tapered shape of roller bearings ensures that they can effectively handle radial and axial loads, making them an ideal choice for critical applications such as axles and drive systems.

In addition, roller bearings are highly efficient, reducing friction and wear, which is important for conditions that require maintaining high speeds and reducing operating costs. The strong construction materials and special coatings of roller bearings further enhance their durability and protect against environmental challenges such as dust, water and changing temperatures. Therefore, the combination of load capacity, efficiency and durability makes roller bearings an important choice for maintaining the safety, performance and cost-effectiveness of railway systems.

Common Materials Used In Railway Bearings

Railway bearings are made of a variety of materials, commonly used materials include advanced steel alloys, which have high strength and fatigue resistance. Advanced alloys may also contain chromium, molybdenum and nickel, which can enhance corrosion resistance and toughness, allowing bearings to operate normally in harsh environmental conditions.

In addition, ceramics and composite materials are increasingly used in railway bearings to reduce weight and improve wear resistance. For example, ceramics have excellent hardness and low friction properties, which can reduce energy loss and improve train efficiency. Composite materials are often reinforced with carbon fiber or glass fiber, have excellent strength-to-weight ratio and resistance to environmental degradation. Together, these materials improve the overall performance of railway bearings, improve durability, reduce maintenance requirements and improve operational efficiency.

Application Areas Of Railway Bearings

- Maintenance vehicles – vehicles used to inspect and repair tracks and other railway infrastructure.

- Signal equipment – in machinery for railway signal systems.

- Station conveyor systems – conveyor systems used to handle luggage and freight.

- Track laying machines – bearings used in machines for laying and maintaining track.

- Railroad service tools – included in various tools and equipment used for railway construction and maintenance.

- Railroad bridge rotating segments – used in movable bridge segments.

- Door mechanism bearings – used in automatic and manual door systems for trains.

- Railroad depot turntables – enable locomotives and railcars to turn and position within depots.

- Freight terminal equipment – equipment used for loading, unloading, and moving heavy freight.

The Role Of Railway Bearings In Ensuring Safety

Railway bearings play a vital role in the safety of the railway industry by maintaining the structural integrity and reliable operation of a variety of critical components such as wheels, axles, bogies, etc. By facilitating smooth movement, bearings reduce the risk of mechanical failures that could lead to derailment or other accidents. Bearings can withstand heavy loads and withstand harsh conditions, reduce the occurrence of failures, and maintain consistent performance under different operating pressures. In addition, the durability of bearings directly contributes to the safe long-term operation of trains, especially in critical systems such as traction motors and gearboxes. By improving reliability and reducing maintenance frequency, bearings help ensure that trains operate within safety parameters, thereby safeguarding the transportation of passengers and freight on the vast railway network. This highlights the key role of railway bearings in the railway industry.

Impact Of Railway Bearings On Train Performance

Railway bearings are key to keeping trains running smoothly and efficiently. They reduce friction, allowing trains to run faster and use less energy. Their sturdy design means less repair work and more time on the track. Plus, they help reduce noise and bumps, making the journey more comfortable for everyone. As someone who makes these bearings, I can tell you that they are essential for safe, fast, and comfortable rail travel.

Challenges Faced By Railway Bearings In The Industry

Railway bearings must withstand extreme weather, heavy loads, and constant vibration. Keeping them running smoothly requires top-notch materials and design, as any failure could cause serious delays and safety issues. As bearing manufacturers, it’s our job to ensure these little components of the rail world are strong, reliable, and work smoothly. They’re more than just metal parts; they’re at the heart of train reliability and safety.

Conclusion

Railway bearings are more than just a small part of a train assembly; they handle heavy loads, reduce wear and improve passenger comfort by minimizing noise and vibration. They are key to ensuring safe and efficient operation of trains. With technological advances and innovative materials, the future of railway bearings is full of possibilities. Hopefully, this article will help you better understand these seemingly simple yet vital components and how they play an irreplaceable role in our daily travel.

References

- 1. Introduction and Features of ”Railway Bearings “from NTN

- 2. ”Bearings for Railway Applications “from NSK

- 3. Additional Analysis on “Railway Bearings ”from Bronzelube Company