Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Redundancy and Fault Tolerance in Robotic Bearing Systems: Ensuring Robustness and Reliability

Introduction

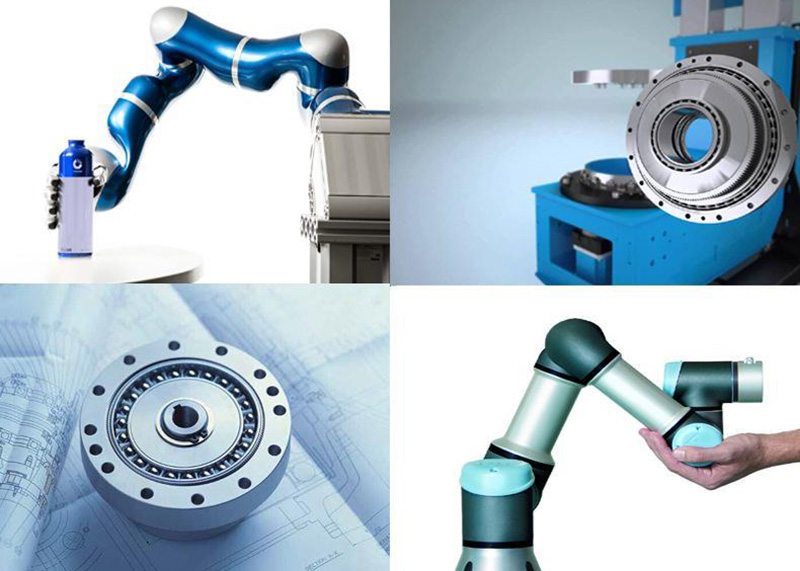

Importance of Robotic Bearing Systems in Industrial Applications

Robotic bearing systems play a pivotal role in industrial applications, serving as the backbone of machinery and equipment across various sectors. These bearings facilitate smooth motion, reduce friction, and support heavy loads, ensuring optimal performance of robotic arms, conveyor belts, and precision machinery. Their precise construction and durable materials enable consistent operation in harsh environments, from manufacturing floors to automotive assembly lines. Without reliable bearing systems, industrial processes would suffer from inefficiencies, downtime, and compromised product quality. Therefore, the significance of robust and reliable robotic bearing systems cannot be overstated in maintaining productivity and competitiveness in modern industrial settings.

Significance of Redundancy and Fault Tolerance

In the realm of robotic bearing systems, the significance of redundancy and fault tolerance lies in ensuring uninterrupted operation and mitigating the risk of catastrophic failures. Redundancy, through duplicating critical components or functions, provides a safety net against unexpected malfunctions or breakdowns, enhancing system reliability and uptime. Meanwhile, fault tolerance techniques enable early detection of anomalies and facilitate swift corrective actions to prevent system downtime. By incorporating redundancy and fault tolerance strategies, robotic bearing systems can withstand unexpected challenges, such as component failures or environmental stresses, ensuring uninterrupted performance in critical industrial applications.

Understanding Robotic Bearing Systems

Understanding robotic bearing systems is essential for grasping their crucial role in various industrial applications. Robotic bearings, at their core, are precision-engineered components designed to facilitate smooth motion, reduce friction, and support heavy loads within robotic arms, conveyor belts, and other machinery.

These bearings come in various types, each with distinct characteristics suited for different applications. Common types include ball bearings, known for their low friction and high-speed capabilities, roller bearings, ideal for handling radial and axial loads, and plain bearings, which offer simplicity and low maintenance requirements.

Regardless of type, robotic bearings play a critical role in ensuring the smooth operation of industrial processes. They enable precise movement and positioning of robotic arms, contribute to the efficiency of conveyor systems, and support the reliable operation of machinery in manufacturing and assembly lines. Without robust and reliable bearing systems, the performance of industrial equipment would be compromised, leading to reduced productivity, increased maintenance costs, and potential safety hazards. Therefore, understanding the function and importance of robotic bearings is fundamental for optimizing industrial operations and ensuring their long-term reliability.

Importance of Redundancy in Robotic Bearings

Definition of Redundancy in Engineering

In the context of robotic bearings, redundancy in engineering refers to the incorporation of duplicate components or functions within a system to enhance reliability and fault tolerance. This redundancy acts as a safety net against unexpected failures, ensuring uninterrupted operation even in the event of a component malfunction. By having redundant elements in place, such as backup bearings or redundant sensor systems, robotic bearing systems can continue functioning without significant interruption, minimizing downtime and maintaining productivity. Redundancy also provides a means of fault isolation and recovery, allowing the system to identify and mitigate failures promptly. In essence, redundancy in robotic bearings is a proactive approach to mitigating risks and ensuring consistent performance in critical industrial applications.

Redundancy Strategies in Robotic Bearing Systems

Redundancy strategies in robotic bearing systems are fundamental for ensuring robustness and reliability in critical industrial applications. These strategies involve the integration of duplicate components or functions within the system to provide backup solutions in the event of a failure. One common approach is component redundancy, where critical components such as bearings or sensors are duplicated to ensure continuity of operation. Additionally, functional redundancy ensures that essential functions performed by the bearings, such as load-bearing or motion control, have backup systems in place. By implementing redundancy strategies, robotic bearing systems can withstand unexpected challenges, minimize downtime, and maintain productivity. Moreover, redundancy enhances fault tolerance by providing alternative pathways for operation, enabling the system to adapt and recover from failures swiftly.

Benefits of Redundancy in Mitigating Failures

The importance of redundancy in robotic bearings lies in its ability to mitigate failures and ensure uninterrupted operation in critical industrial settings. One of the primary benefits of redundancy is its capacity to provide backup solutions in the event of component failures. By duplicating critical components or functions within the system, redundancy offers alternative pathways for operation, reducing the impact of failures on overall system performance. Additionally, redundancy enhances fault tolerance by enabling the system to adapt and continue functioning even in the presence of faults or malfunctions. This proactive approach minimizes downtime, increases reliability, and maintains productivity in industrial applications where continuous operation is paramount. Ultimately, the incorporation of redundancy in robotic bearing systems offers a safeguard against unexpected failures, ensuring smooth operation and peace of mind for industrial operators.

Fault Tolerance Techniques in Robotic Bearings

Definition of Fault Tolerance

In the realm of robotic bearings, fault tolerance refers to the system’s ability to continue functioning and deliver acceptable performance despite the presence of faults or malfunctions. This concept involves implementing techniques and mechanisms to detect, isolate, and recover from faults, thereby ensuring uninterrupted operation in critical industrial applications. Fault tolerance techniques aim to minimize the impact of faults on system performance, preventing catastrophic failures and mitigating potential risks. By incorporating fault tolerance mechanisms, such as sensor integration for real-time monitoring or adaptive control systems for proactive adjustments, robotic bearing systems can detect anomalies early, respond effectively to deviations from normal operation, and maintain productivity in demanding industrial environments. In essence, fault tolerance in robotic bearings is a proactive approach to safeguarding against potential failures and ensuring the reliability and robustness of the system.

Fault Detection and Diagnostics

Fault detection and diagnostics are critical aspects of fault tolerance techniques in robotic bearing systems, aimed at identifying anomalies and deviations from normal operation to prevent potential failures. These techniques involve the integration of sensors and monitoring systems to continuously assess the health and performance of the bearings. By analyzing sensor data in real-time, robotic bearing systems can detect early warning signs of potential faults, such as excessive vibration, temperature variations, or abnormal noise levels. Additionally, advanced diagnostic algorithms enable the system to pinpoint the root cause of anomalies, facilitating swift corrective actions and preventing the escalation of issues. By implementing robust fault detection and diagnostics mechanisms, robotic bearing systems can proactively identify and address potential failures before they impact system performance, ensuring uninterrupted operation and minimizing downtime in critical industrial applications.

Fault Isolation and Recovery Mechanisms

Fault isolation and recovery mechanisms are integral components of fault tolerance techniques in robotic bearing systems, designed to mitigate the impact of faults and ensure continuous operation. These mechanisms involve the implementation of adaptive control systems and self-repairing capabilities to isolate faulty components and restore functionality. Adaptive control systems dynamically adjust system parameters based on sensor feedback to compensate for deviations caused by faults, allowing the system to maintain performance within acceptable limits. Additionally, self-repairing bearings utilize innovative technologies such as self-healing materials or automated repair processes to rectify minor faults and restore functionality without human intervention. By incorporating fault isolation and recovery mechanisms, robotic bearing systems can effectively mitigate the impact of faults, minimize downtime, and enhance overall system reliability in critical industrial applications.

Design Considerations for Redundant Bearing Systems

Structural Design Considerations

Structural design considerations are paramount when implementing redundant bearing systems in industrial applications, ensuring optimal performance and reliability. These considerations encompass various aspects, including bearing placement and configuration, to distribute loads evenly and minimize stress concentrations. Additionally, engineers must carefully select materials and design features to withstand the demands of the operating environment while maintaining structural integrity. Load distribution strategies play a crucial role in optimizing the performance of redundant bearing systems, balancing the load across multiple bearings to prevent overloading and premature failure. Moreover, the structural design should accommodate easy access for maintenance and replacement of redundant components, minimizing downtime and ensuring uninterrupted operation.

Material Selection for Redundant Bearings

Material selection for redundant bearings is a critical aspect of designing robust and reliable systems for industrial applications. Engineers must carefully consider various factors such as load capacity, durability, and environmental conditions when selecting materials for redundant bearings. High-strength alloys are often preferred for their excellent mechanical properties, including high tensile strength and fatigue resistance, making them suitable for handling heavy loads and prolonged operation. Additionally, ceramic bearings offer advantages such as superior corrosion resistance and reduced friction, making them ideal for applications in harsh environments or high-speed rotating machinery. By choosing materials that can withstand the demands of the operating environment while maintaining dimensional stability and performance, engineers can ensure the longevity and reliability of redundant bearing systems in critical industrial applications.

Environmental Factors and Redundant Bearing Performance

Environmental factors play a crucial role in determining the performance and reliability of redundant bearing systems in industrial applications. Engineers must consider various environmental conditions, such as temperature extremes, humidity levels, and exposure to contaminants, when designing redundant bearing systems. For example, in applications subjected to high temperatures or corrosive environments, engineers may opt for materials with enhanced heat resistance or corrosion protection to ensure long-term performance. Additionally, proper sealing and lubrication are essential to prevent ingress of contaminants and maintain optimal operation of redundant bearings. By carefully evaluating environmental factors and implementing appropriate design measures, engineers can enhance the robustness and reliability of redundant bearing systems, ensuring uninterrupted operation in demanding industrial environments.

Implementation Challenges and Solutions

Cost-Effectiveness of Redundant Systems

Implementing redundant systems in robotic bearing applications often poses challenges related to cost-effectiveness. The duplication of components and integration of backup systems can increase initial investment and ongoing maintenance expenses. However, engineers can address these challenges through careful cost-benefit analysis and the adoption of economical redundancy solutions. This may involve prioritizing redundancy for critical components while optimizing costs for less critical elements. Additionally, advancements in technology and manufacturing processes enable the development of cost-effective redundant systems without compromising performance or reliability. Retrofitting existing systems with redundant components and leveraging standardized designs can further reduce implementation costs. By balancing the upfront investment with long-term benefits, engineers can ensure the cost-effectiveness of redundant systems while enhancing the reliability and robustness of robotic bearing applications.

Integration with Existing Robotic Systems

Integrating redundant bearing systems with existing robotic systems presents challenges that require careful consideration and innovative solutions. Retrofitting redundant components into established systems may pose compatibility issues with existing hardware and control systems. Engineers must ensure seamless integration by designing redundant bearings that align with the specifications and operating parameters of the existing system. Compatibility testing and validation are essential to identify potential conflicts and ensure optimal performance post-implementation. Moreover, incorporating redundancy may necessitate adjustments to control algorithms and software interfaces to accommodate the redundant components effectively. Utilizing modular designs and standardized interfaces can streamline integration efforts and minimize disruption to ongoing operations. By addressing integration challenges proactively and leveraging flexible design approaches, engineers can seamlessly integrate redundant bearing systems into existing robotic platforms, enhancing reliability and ensuring uninterrupted operation.

Conclusion

In conclusion, robotic bearing systems are indispensable in industrial applications, ensuring smooth operation and productivity across various sectors. Incorporating redundancy and fault tolerance mechanisms is crucial for mitigating failures and maintaining uninterrupted performance. By understanding the significance of redundancy, fault tolerance techniques, and design considerations, engineers can develop robust and reliable bearing systems capable of withstanding the challenges of demanding industrial environments. Despite implementation challenges, careful consideration of cost-effectiveness and seamless integration with existing systems can maximize the benefits of redundancy while enhancing reliability. Ultimately, prioritizing redundancy and fault tolerance in robotic bearing systems is essential for optimizing industrial operations and ensuring long-term competitiveness in today’s dynamic manufacturing landscape.

References

- 1.”Automation and robotic bearings guide” from SMB Bearings;

- 2. “Bearing solutions and dynamic motion systems for robot-based automation” from Bearing NEWS;

- 3. “Enable high payloads and space-savings for high-performing robots” from SKF Bearings.