Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Tapered Roller Bearings: Precision Beyond Measure

Introduction

Unlocking Precision: Dive into the World of Tapered Roller Bearings. In the realm of mechanical efficiency, tapered roller bearings play a pivotal role. Join us on a journey to explore the inner workings of these crucial components, delving into their design, applications, and the precision they bring to various industries. Get ready to discover how these bearings seamlessly handle radial and axial loads, ensuring smooth operations in machinery and beyond.

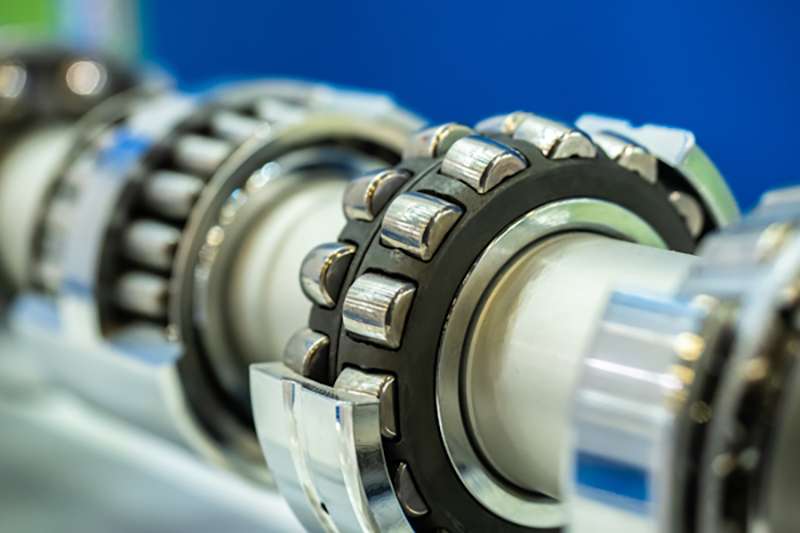

The Anatomy of Tapered Precision

- Tapered roller bearings stand as exemplars of engineering precision, with intricate design features meticulously incorporated. The careful consideration of contours, angles, and material selection underscores a commitment to optimal functionality. Each element, from the precision-engineered rollers to the meticulously crafted cages, contributes to the bearings’ overall performance.

- The crux of their exceptional performance lies in the tapered structure. This design not only facilitates the efficient distribution of radial and axial loads but also promotes increased contact area and rigidity. The taper ensures a controlled and uniform rolling motion, minimizing friction and wear. This structural advantage translates into enhanced durability, reduced maintenance, and improved operational efficiency.

In essence, the taper accuracy of tapered roller bearings showcases a harmonious fusion of design intricacies and structural prowess, positioning these bearings as indispensable components for reliable and high-performance machinery across diverse industries.

Efficiency Physics of Tapered Roller Bearings

How tapered roller bearings optimize energy consumption

Tapered roller bearings, beyond their role in load management and mechanical precision, emerge as pivotal components in optimizing energy consumption. These bearings, with their specialized tapered design, significantly contribute to efficiency gains in various applications. The tapered structure minimizes frictional resistance during rotation, reducing energy losses and promoting smoother operation. By facilitating precise load distribution, these bearings enhance overall machinery performance while simultaneously curbing energy demands. This optimization not only translates into cost savings but also aligns with the growing emphasis on sustainability and resource efficiency. In exploring how tapered roller bearings optimize energy consumption, we unravel a crucial aspect of their multifaceted impact on the functionality and eco-friendliness of diverse mechanical systems.

Contributions to overall mechanical system efficiency

Tapered roller bearings stand as unsung heroes in the realm of mechanical systems, making indispensable contributions to overall efficiency. With their precision-engineered design, these bearings minimize friction, ensuring seamless load distribution and reduced energy consumption. By enhancing reliability and reducing wear, tapered roller bearings play a vital role in promoting the longevity and optimal performance of machinery. In this exploration of their contributions, we uncover how these unassuming components serve as linchpins in the quest for heightened mechanical system efficiency.

The Evolution of Tapered Excellence

The historical evolution of tapered roller bearings has been marked by significant milestones and transformative innovations. Originating in the early 20th century, the first notable breakthrough was the introduction of the tapered roller bearing design, which greatly enhanced load-carrying capacities. Subsequent decades witnessed advancements in material science, with the integration of high-quality alloys and heat treatment techniques, improving durability and performance. In the latter half of the 20th century, computer-aided design revolutionized the precision and efficiency of tapered roller bearings, allowing for intricate optimizations.

Recent innovations include advanced manufacturing technologies, such as precision machining and surface treatments, further refining their capabilities. Today, tapered roller bearings stand as a testament to a century of continuous improvement, combining historical milestones with cutting-edge innovations to provide reliable, high-performance solutions across diverse industrial applications.

Size Matters: Micro and Macro Applications

Tapered roller bearings, versatile in their design and applications, find utility in both micro and macro contexts, showcasing their adaptability across a spectrum of industries. At the micro level, these bearings play a crucial role in intricate machinery and precision instruments, ensuring smooth and precise motion. Their ability to handle radial and axial loads with precision makes them indispensable in miniaturized devices where every component’s efficiency is paramount.

On the macro scale, tapered roller bearings excel in heavy machinery, automotive systems, and industrial equipment. Their robust design and load-bearing capabilities contribute to the reliable functioning of large-scale applications, enhancing the overall performance and longevity of diverse mechanical systems. Whether in the precision-driven world of microtechnology or the robust demands of macro-level industries, tapered roller bearings emerge as indispensable components, seamlessly bridging the gap between intricate precision and heavy-duty reliability.

Artificial Intelligence Meets Bearings

The integration of artificial intelligence (AI) marks a groundbreaking chapter in optimizing the performance of tapered roller bearings. AI-driven systems, through advanced data analytics and machine learning algorithms, offer real-time monitoring of bearing conditions, enabling predictive maintenance and minimizing downtime. These smart systems can identify patterns, detect anomalies, and optimize lubrication, contributing to enhanced efficiency and extended bearing life.

Looking ahead, the future possibilities are both exciting and transformative. AI could usher in innovations like self-adjusting bearings, adapting dynamically to varying loads and conditions. Collaborative networks of AI-enhanced bearings may communicate seamlessly, collectively optimizing the performance of an entire mechanical system.

The marriage of AI and tapered roller bearings holds the promise of not just improving current operational parameters but also unlocking new frontiers in reliability, autonomy, and efficiency, thereby shaping the future landscape of mechanical engineering.

Breaking the Mold: Unconventional Materials

The exploration of alternative materials for tapered roller bearings beyond traditional steel represents a paradigm shift in enhancing durability and performance.

Innovations in engineering have led to the incorporation of advanced materials such as ceramic, composites, and polymers. Ceramic bearings, for instance, boast superior hardness and resistance to corrosion, offering reduced friction and extended lifespan. Composites, with their tailored properties, provide a balance of strength and lightweight characteristics, contributing to improved efficiency. Polymer bearings, on the other hand, excel in corrosive environments due to their non-metallic composition. These alternative materials not only diversify the options for specific application needs but also address challenges associated with traditional steel bearings, such as susceptibility to corrosion and high friction.

The impact on durability and performance is profound, as these materials not only extend the lifespan of tapered roller bearings but also enhance their overall efficiency, making them pivotal components in diverse industries where reliability and longevity are paramount.

Crafting the Future: 3D Printing Bearings

The emergence of 3D printed tapered roller bearings signifies a revolutionary leap in the realm of mechanical engineering, offering unprecedented levels of customization and rapid prototyping. Leveraging additive manufacturing techniques, 3D printing allows for the precise layer-by-layer construction of intricate bearing geometries, tailoring designs to specific application requirements. This level of customization not only optimizes the bearing’s performance by adapting to unique load conditions but also opens doors to innovative applications previously constrained by traditional manufacturing limitations. Additionally, the technology facilitates rapid prototyping, enabling engineers to swiftly iterate and test various designs, accelerating the development cycle. The impact on the industry is transformative, as 3D printed tapered roller bearings redefine the possibilities of bespoke solutions, ushering in an era where adaptability, efficiency, and swift prototyping converge to meet the dynamic needs of modern machinery and diverse industrial applications.

Nanotechnology and Bearings: A Closer Look

While nanoscale applications of tapered roller bearings might not be common due to their typical use in larger mechanical systems, hypothetical scenarios and future advancements in nanotechnology could bring about innovative applications. Here are six speculative nanoscale applications:

Nano-Robotic Systems: Tapered roller bearings at the nanoscale could find applications in tiny robotic systems, facilitating precise movement and load distribution in microenvironments for medical or industrial purposes.

Nanoscale Manufacturing: In nanoscale manufacturing processes, miniaturized machinery may incorporate tapered roller bearings to ensure smooth motion and accuracy, contributing to the production of extremely small and intricate components.

Biomedical Nanodevices: Within the realm of biomedical nanodevices, tapered roller bearings could play a role in nanoscale machines designed for drug delivery, diagnostics, or other medical interventions at the cellular level.

Nanorobotic Surgery: In futuristic scenarios, nanorobots equipped with tapered roller bearings might navigate through the human body with precision, enabling minimally invasive surgeries at the cellular or molecular level.

Nanoscale Sensing Devices: Tapered roller bearings could be integrated into nanoscale sensing devices, allowing for precise movement and positioning in applications such as scanning probe microscopy or nanoscale sensors.

Quantum Computing Components: In the evolving field of quantum computing, nanoscale bearings could be utilized in mechanical components of quantum computers, contributing to the stability and movement of quantum bits or qubits.

It’s important to note that while these applications represent speculative possibilities, current technological limitations may hinder the practical implementation of tapered roller bearings at the nanoscale. Advances in nanotechnology and materials science will play a crucial role in making such applications feasible.

Conclusion

In conclusion, the world of tapered roller bearings is a fascinating intersection of engineering brilliance and practical application. From their humble beginnings to the forefront of technological innovation, these components continue to be indispensable in shaping the machinery that powers our world. As we celebrate their precision beyond measure, the journey of discovery and innovation in the realm of tapered roller bearings is far from over.

References

1.”Tapered roller bearings” from Wikipedia;

2. “Tapered Roller Bearings” from NSK;

3. “Tapered roller bearings” from SKF .