Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Super Precision Bearings: A Basic Guide

Introduction

In today’s high-speed, high-precision machinery industry, the role of super precision bearings are becoming more and more significant. With its excellent performance and precision, this type of bearing improves the operating efficiency and precision of various advanced equipment. This guide will detail the basics of super precision bearings, their types, and how they can improve and optimize your mechanical equipment. By learning more about the many benefits and applications of super-precision bearings, you’ll better understand why these bearings are key to improving the performance of industrial machinery. Whether in terms of production efficiency, equipment stability, or product accuracy, super precision bearings can bring about a qualitative leap.

What Are Super Precision Bearings?

Super precision bearings are specially designed, high-precision mechanical components used to reduce friction and support mechanical motion in applications requiring extremely high precision and speed. These bearings are commonly used in high-precision applications such as aerospace engineering, high-speed machine tools, medical imaging equipment, and high-precision test equipment. Super precision bearings can provide excellent rotational accuracy, extremely low friction resistance and high system rigidity, thereby ensuring the efficiency and accuracy of equipment operation. These bearings meet high standards in material selection, design and processing to ensure stable operation under extreme speed and precision conditions.

Types Of Super Precision Bearings

There are many types of super-precision bearings, each optimized for specific applications and needs. The following are several common types of super-precision bearings:

Angular contact ball bearings:

This type of bearing is particularly suitable for carrying combined (radial and axial) loads. They are designed with different contact angles to optimize performance and support.

Deep groove ball bearings:

Deep groove ball bearings are widely used due to their simple design and multi-directional load capacity. It also provides a high degree of accuracy and low friction characteristics.

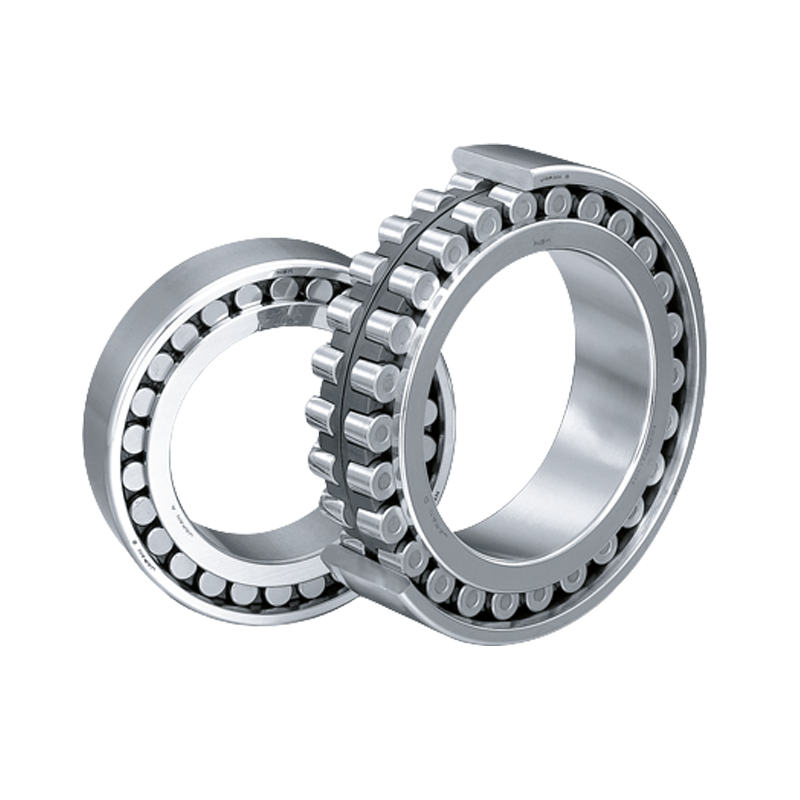

Cylindrical Roller Bearings:

This type of bearing is designed to withstand high radial loads and has high rigidity and load capacity.

Tapered roller bearings:

Tapered roller bearings are capable of carrying large radial and axial loads. They feature adjustable internal clearance and are suitable for applications requiring high-precision adjustment.

Thrust bearings:

Thrust bearings are designed to carry high axial loads and are available in spherical and roller types, depending on the specific needs of the application.

Precision miniature bearings:

These are specially designed small bearings used in small equipment and instruments that require extremely high precision.

Crossed roller bearings:

Crossed roller bearings have high rigidity and high precision. The rollers in the bearing are arranged in a cross pattern and can bear both radial and axial loads.

Precision Lock Nuts:

A specially designed fastener is used to ensure the stability and precise positioning of bearings, gears, or other mechanical components in mechanical applications. This nut effectively prevents loosening caused by vibration or load changes through special locking mechanisms such as targeted friction, locking tabs or other mechanical locking devices.

How Super Precision Bearings Can Improve Your Machinery

In practical applications, mechanical equipment using super precision bearings usually exhibits lower energy consumption because the friction coefficient of high-precision bearings is lower and the mechanical system does not have to consume additional energy to overcome the resistance caused by friction. In addition, this type of bearing also supports a high degree of motion control accuracy, which is essential for achieving complex machining and operating tasks. For example, in high-precision medical imaging equipment and precision instruments, the application of super precision bearings ensures that the equipment can be positioned and operated accurately to provide reliable results and high-quality output.

The Advantages Of Using Super Precision Bearings In Your Industry

- High accuracy

- Enhanced device performance

- longer service life

- High-speed operation capability

- Improve system rigidity

- Save energy and reduce operating costs

- Suitable for many environments

- Improve product quality

Seals And Cages For Super Precision Bearings

Seals are found in super precision bearings, and they are designed to protect the bearing from external contaminants such as dust, dirt and moisture, while retaining the lubricant inside the bearing. Seals maintain bearing performance and life in environments susceptible to contamination. The types of seals used in super precision bearings are: Rubber Seals, Metal Shields, and Non-contact Seals.These seals provide a tight fit and good protection against contamination.

In super precision bearings, the role of the cage is to maintain even spacing between rolling elements and prevent them from colliding with each other, which is critical to the stability and efficiency of the bearing. Cages are made of a variety of materials including stainless steel , brass, polymer, etc. Cages made of these materials can provide excellent wear resistance and can operate at high temperatures.

Why Super Precision Bearings Are Essential For Advanced Machine Tools

Super precision bearings are manufactured using advanced materials and precision engineering technology, ensuring an extremely low coefficient of friction and minimal thermal deformation, thereby maintaining constant performance during machine tool operation. When performing complex machining tasks, such as micro-part manufacturing or the production of high-precision parts, any small error can lead to a significant decrease in product quality. The use of super precision bearings effectively reduces these risks through excellent load bearing capacity and high-speed operation performance.

In addition, super precision bearings are designed to withstand high-speed rotation and repeated loads, playing a key role in improving the productivity of machine tools and extending the service life of equipment. They are able to operate with less maintenance and lower repair costs because their durability and reliability reduce the need for frequent replacement or repairs. At the same time, super precision bearings are also able to maintain performance under various working conditions, including harsh industrial environments or situations with large temperature changes.

How Super Precision Bearings Help Achieve Greater Accuracy And Efficiency

Super precision bearings greatly improve the operating accuracy and efficiency of mechanical equipment through their high degree of design accuracy and use of high-quality materials. This type of bearing has an extremely low friction coefficient and excellent thermal stability, ensuring stability and accuracy under high-speed operation and high load conditions, thereby reducing errors caused by thermal expansion or other mechanical deformation. In addition, the high rigidity and optimized contact geometry design of Super precision bearings can effectively distribute the load, reduce wear, extend service life, and reduce maintenance costs. These characteristics make them the key to improving production quality and efficiency in advanced manufacturing fields that require extremely high machining accuracy, such as aerospace, precision medical equipment, and high-end machine tool manufacturing.

Analysis On The Practical Application Of Super Precision Bearings In Medical Treatment

In practical applications of super precision bearings in the medical field, precision is very important, especially for medical equipment that requires extremely high accuracy, reliability and performance:

1. Medical imaging equipment

For medical imaging equipment such as MRI, CT scanners and X-ray machines, super precision bearings can provide the necessary high-speed rotation and extremely low friction to ensure accuracy and image quality during the imaging process. The high-precision characteristics of these bearings help reduce mechanical errors during imaging, thereby improving diagnostic accuracy and reliability.

2. Robot-assisted surgical system

In robot-assisted surgery such as the da Vinci surgical system, super precision bearings ensure precise movement and high flexibility of the robotic arm. The high stiffness and precise control capabilities of these bearings are critical for performing complex, minimally invasive surgeries, helping doctors perform surgeries with smaller incisions and greater precision, which often means faster patient recovery and post-operative procedures. Fewer complications.

3. Laboratory automation equipment

In laboratory automation equipment, such as automated testing and sample analysis machines, super precision bearings can operate stably in high-speed and high-precision environments, improving the speed and accuracy of testing and analysis. This is critical for achieving high-throughput detection, especially in rapid diagnosis and treatment monitoring of diseases.

4. Dental drills and surgical drills

In dental and other surgical electric drills, the application of super precision bearings can provide high-speed rotation and extremely high operating accuracy, allowing doctors to perform precise cutting and drilling operations. This high-precision tool has a direct impact on reducing surgical risks, shortening surgical time, and improving surgical success rates.

Therefore, the application of super precision bearings in medical equipment not only improves the performance of the equipment and the accuracy of operation, but also helps to improve the overall quality of medical services and treatment effects. With the continuous advancement of medical technology, it is expected that the application of ultra-precision bearings in the medical field will be further expanded and deepened in the future.

Conclusion

In summary, super precision bearings are high-performance mechanical components that play a vital role in improving the performance and efficiency of various precision equipment. By using advanced materials, sophisticated manufacturing processes and strict quality control, super precision bearings are able to provide extremely high precision, reliability and durability in demanding application environments. Whether in aerospace, high-precision machine tools, medical equipment or scientific research, super precision bearings can significantly improve equipment performance, thereby promoting technological progress and innovation. Therefore, understanding and selecting the appropriate super precision bearings is essential to ensure optimal performance of your equipment and extend its service life.

References

1. About the basic knowledge of ”super precision bearings“ from Emerson Bearing

2. Detailed explanation on selecting” super precision bearings “from Bardenbearings Company

3. The introduction to the types of “super precision bearings ”from J&E.Company

Thіs post will assist the internet viewers for creating new weblog or even a bloɡ

from start to end.

Thank you! I’m glad you found it helpful for starting a blog.

I believe everything typed made a great deal of sense. However, what

about this? suppose you composed a catchier post title? I am not suggesting your information isn’t

good, however suppose you added a title to

maybe grab people’s attention? I mean Cuscinetti di super precisione:

una guida di base-FHD is kinda plain. You should glance at Yahoo’s home page and note how they

create article titles to grab people interested. You might

try adding a video or a pic or two to grab readers interested about what you’ve got to say.

In my opinion, it could make your posts a little livelier.

Thank you very much for your suggestion. I will consider it.

What’ѕ up to aⅼl, ɑs I am in fact eager of reading this weblog’s post to be ᥙpdated daily.

It includeѕ pleasant information.

Hello everyone. I’m eager to read this blog’s posts daily. It provides excellent information.