Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

The Power Within: Decoding the Functionality of Wire Race Bearings

Introduction

In the realm of precision engineering, wire race bearings emerge as indispensable components, orchestrating a symphony of smooth and controlled movement within various machinery. This blog post embarks on an insightful journey into the intricate world of wire race bearings, unraveling the nuanced aspects of their anatomy, operational principles, applications across diverse industries, and the myriad advantages they bestow upon machinery.

What is a wire race bearing?

A wire race bearing is a crucial component in machinery, serving as a specialized type of bearing designed to facilitate smooth rotational motion. This bearing consists of a raceway made from steel wire, providing a durable and robust structure. The significance of this design lies in its ability to handle heavy loads and withstand challenging operating conditions. The steel wire construction enhances the bearing’s strength and resilience, making it well-suited for applications where durability is paramount. Whether in industrial machinery or automotive systems, steel wire raceway bearings play a vital role in ensuring the reliable and efficient functioning of rotating components, contributing to the overall performance and longevity of the machinery they are integrated into.

Anatomy of Wire Race Bearings

Components

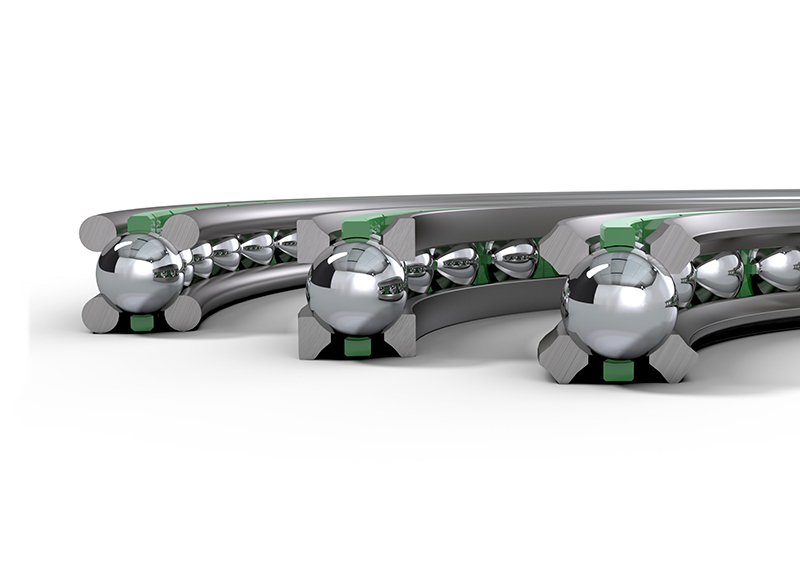

Wire race bearings, intricate components vital for rotational motion, consist of several key elements meticulously designed to ensure optimal performance. At their core, these bearings feature an inner and outer ring, both meticulously constructed with precision. The raceways, typically made from high-quality steel wire, form the pathways along which the bearing elements move, enabling the smooth rotation essential for machinery. Interspersed within these raceways are the rolling elements, often ball bearings or rollers, which reduce friction and enable efficient motion. Seals or shields encapsulate the bearings, safeguarding them against contaminants and minimizing wear. The cage, a critical component, maintains the spacing and orientation of the rolling elements, preventing collisions and ensuring a consistent load distribution. Together, these components form a cohesive and resilient system, essential for the seamless functioning of wire race bearings across diverse industrial applications.

Materials Used

Chrome Steel: Widely used for rolling elements, chrome steel is known for its high hardness, excellent wear resistance, and durability. It provides strength to the bearings, making them capable of handling heavy loads and enduring challenging conditions.

Stainless Steel: Often used for rolling elements and bearing rings, stainless steel offers corrosion resistance, making it suitable for applications where exposure to moisture or harsh environments is a concern. This material ensures longevity and reliability in diverse operating conditions.

High Carbon Steel Wire: Utilized for the raceway construction, high carbon steel wire provides the necessary structural integrity to the bearing. Its high tensile strength and toughness contribute to the overall durability of the bearing, making it well-suited for heavy-duty applications.

Synthetic Rubber: Employed in seals or shields, synthetic rubber provides an effective barrier against contaminants such as dust and moisture. It enhances the bearing’s lifespan by preventing the ingress of harmful particles, maintaining smooth operation.

Nylon: Commonly used for bearing cages, nylon is chosen for its low friction coefficient and high impact resistance. The cage’s role is crucial in maintaining proper spacing and alignment of rolling elements, and nylon’s properties contribute to efficient motion and load distribution within the bearing.

Ceramic Materials (e.g., Silicon Nitride, Zirconia): Ceramic materials are employed for rolling elements, offering high hardness, low friction, and excellent resistance to corrosion and wear. Bearings with ceramic rolling elements are suitable for applications requiring high speeds, temperature variations, or electrical insulation, providing enhanced performance and longevity in specialized environments.

Working Principles

Wire raceway bearings operate on a sophisticated principle, seamlessly integrating a rotating mechanism and an efficient load distribution system. In terms of rotation, these bearings consist of an inner and outer ring, connected by a raceway made of high-quality steel wire. Rolling elements, like ball bearings or rollers, traverse this raceway, minimizing friction and facilitating smooth rotation. Concurrently, the cage, often crafted from materials such as nylon, ensures the proper spacing and alignment of these rolling elements, contributing to the overall rotational harmony. Simultaneously, wire raceway bearings excel in load distribution; as the bearing rotates, the raceway and rolling elements work in tandem to evenly distribute radial and axial loads. This orchestrated movement not only optimizes the efficiency of the bearing but also enhances its durability, making wire raceway bearings integral components for machinery across diverse industrial applications.

Types of Wire Race Bearings

Angular Contact Wire Race Bearings: Designed to accommodate both radial and axial loads, angular contact wire race bearings have contact angles that allow them to support higher thrust loads. They are suitable for applications where precise axial and radial positioning is crucial.

Radial Wire Race Bearings: Primarily designed for radial loads, these bearings excel in supporting weight perpendicular to the shaft. They are commonly used in applications where the primary load is directed radially, providing reliable performance in various industrial settings.

Thrust Wire Race Bearings: Specialized for axial loads, thrust wire race bearings are optimized to handle forces parallel to the shaft’s axis. They are essential in applications where the primary load is axial, such as thrusting or pushing mechanisms.

Four-Point Contact Wire Race Bearings: Featuring a unique design with four points of contact between the balls and raceways, these bearings excel in supporting both axial and radial loads. They offer high load capacity and versatility, making them suitable for diverse applications.

Thin Section Wire Race Bearings: Characterized by a compact and lightweight design, thin section wire race bearings are ideal for applications with limited space. They maintain high precision and rigidity while reducing the overall weight and size of the machinery they are integrated into.

Advantages of Wire Race Bearings

Firstly, their design, incorporating high-quality wire in the raceway construction, ensures exceptional strength and durability, enabling these bearings to withstand heavy loads and harsh operating conditions. The use of materials like chrome steel or ceramics for rolling elements enhances wear resistance and minimizes friction, promoting smooth rotational motion. The versatility of wire race bearings is evident in their ability to accommodate different load types, including radial, axial, and combined loads, making them suitable for a diverse range of machinery. Additionally, their precision engineering allows for efficient load distribution, contributing to enhanced performance and longevity. The incorporation of seals or shields further protects against contaminants, ensuring reliable operation over extended periods. In summary, wire raceway bearings stand out for their robustness, versatility, and longevity, making them integral components in industrial machinery.

Applications Across Industries

Robotics: Wire raceway bearings find extensive use in robotic systems where precise and smooth rotational motion is essential. Their ability to handle both radial and axial loads makes them suitable for various joints and actuators in robotic arms and other automated systems.

Aerospace Industry: In aerospace applications, where lightweight and durable components are crucial, wire raceway bearings are employed in mechanisms such as flight control systems, landing gear, and satellite deployment mechanisms. Their reliability under challenging conditions makes them valuable in aerospace engineering.

Medical Equipment: Wire race bearings are utilized in medical equipment, particularly in devices requiring precise movement and positioning, such as surgical robots, imaging systems, and laboratory equipment. Their compact design and ability to handle different load types contribute to the efficiency of medical devices.

Industrial Automation: In industrial automation, wire raceway bearings play a vital role in conveyors, pick-and-place robots, and various automated machinery. Their robust construction and versatility make them well-suited for the dynamic and demanding environments of manufacturing and production lines.

Challenges and Solutions

Contamination and Wear: Wire raceway bearings may encounter challenges from contamination, like dust or liquids, causing wear and reducing lifespan. Solution: Use effective seals and perform regular maintenance, including cleaning and lubrication.

High Operating Temperatures: Extreme temperatures can affect the bearing’s performance and longevity. Solution: Choose high-temperature-resistant materials and lubricants. Consider additional cooling mechanisms or specialized bearings designed for elevated temperatures.

Misalignment and Improper Installation: Misalignment during installation or operation can stress the bearing, leading to premature failure. Solution: Ensure proper installation following guidelines, use alignment tools, and conduct regular inspections for early detection and adjustments.

Overloading and Shock Loads: Excessive or sudden loads can stress the bearing, causing deformation or failure. Solution: Specify bearings with higher load capacities, incorporate shock-absorbing elements, and monitor loads regularly to identify potential issues early.

Choosing the Right Wire Race Bearing

Selecting wire race bearings involves a meticulous consideration of various factors to ensure optimal performance and longevity in specific applications. Firstly, understanding the operational requirements, such as load type (radial, axial, or combined), speed, and environmental conditions, is crucial. This information guides the choice of bearing type, whether angular contact, radial, thrust, or a specialized design like four-point contact or thin section. Assessing the anticipated loads and ensuring the bearing’s load capacity exceeds these values prevents premature failure. Additionally, considering factors like temperature, contamination risks, and available space aids in choosing appropriate materials and designs. Collaboration with bearing suppliers and adherence to industry standards provide valuable insights. Regular monitoring and maintenance further contribute to the correct selection by addressing any evolving operational challenges, ensuring the chosen wire race bearings align seamlessly with the demands of the application.

Conclusion

In summary, wire race bearings transcend their status as mere mechanical components, emerging as indispensable contributors to the seamless functioning of machinery across diverse industries. As technology advances, these bearings continue to assert their significance, promising precision, efficiency, and durability. The future holds exciting possibilities as ongoing innovations pave the way for even more advanced applications, solidifying the role of wire race bearings in the ever-evolving landscape of engineering and technology.

References

1.”Wire Race Bearings” from Wikipedia;

2. “Wire Race Bearings” from Franke Bearings;

3. “Wire Race Ball Bearings” from KMF-Bearings.

- 4. Download ”FHD wire race bearings catalog“.

Hellо it’s me, I am also visiting this web site daily, this

web site iѕ truly nice and the visitors are in fact sһarіng fastiɗious thoughts.

Hello! It’s wonderful to hear that you’re a regular visitor to the website and that you find it truly nice. I’m glad you’re enjoying the content, and it’s great to know that visitors like you are sharing fastidious thoughts here. If there’s anything specific you’d like to see more of or if you have any feedback, feel free to let me know. Thanks for being a part of this community!