Ball Bearings

Table of Contents

Definition of Ball Bearings

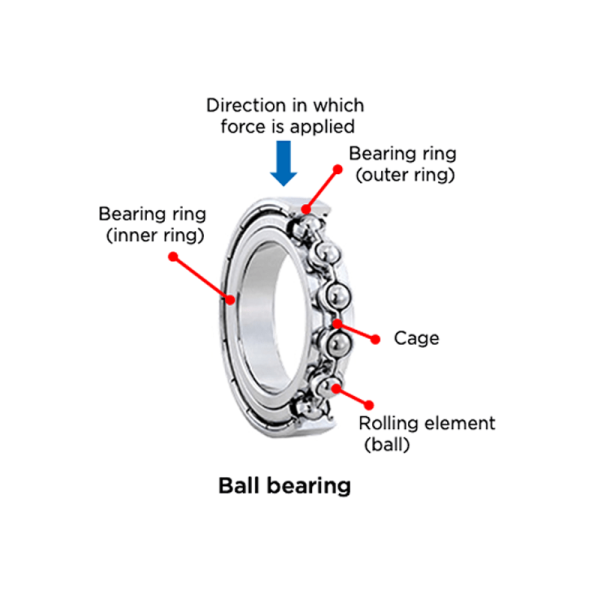

Ball bearings are essential mechanical elements, consisting of a series of spherical balls enclosed within a circular ring or cage. Typically crafted from materials like steel or ceramic, they incorporate a retainer or cage to ensure the uniform positioning of the balls. This specific arrangement empowers them to fulfill critical roles in a wide array of machinery and industrial applications.

FHD Bearings is an ISO 9001:2015 certified manufacturing enterprise that stocks a full range of deep groove ball bearings, angular contact ball bearings, thrust ball bearings, Self-aligning ball bearings and ceramic ball bearings. With over 1,200 different bearing sizes and over 250K bearings in stock.

Materials of Ball Bearings

– The most common material for ball bearings due to its high durability and affordability.

– Offers corrosion resistance and is suitable for applications where hygiene is important.

– Known for its exceptional hardness, low weight, and resistance to high temperatures and corrosion.

– Combines high hardness and corrosion resistance, often used in high-performance applications.

Polyethylene

– Used in applications where non-metallic, lightweight, and corrosion-resistant bearings are required.

Polypropylene

– Suitable for applications with low loads and chemical resistance needs.

Features of Ball Bearings

- Low Friction: Ball bearings are designed to reduce friction between moving parts, leading to energy efficiency and smooth operation.

- Radial and Axial Load Support: They can support both radial (perpendicular to the shaft) and axial (parallel to the shaft) loads, making them versatile for various applications.

- Compact Design: Ball bearings are relatively small and compact, making them suitable for applications with limited space.

- High Speed Capability: They are capable of operating at high speeds, which is essential in many industrial and automotive applications.

- Low Noise and Vibration: Properly lubricated ball bearings produce minimal noise and vibration, contributing to a quieter and smoother operation of machinery.

- Corrosion Resistance: Stainless steel and ceramic ball bearings are known for their resistance to corrosion, making them suitable for harsh environments.

- High Precision: Ball bearings provide precise and consistent motion, critical in applications requiring accuracy.

- Customization: Some ball bearings can be customized for specific applications, including OEM and ODM options.

Advantages of Ball Bearings

- Enhanced Performance: Improved efficiency and reduced wear in machinery.

- High Load Capacity: They can support both radial and axial loads, making them versatile and capable of handling various types of forces.

- Smooth Operation: Ball bearings provide smooth and precise motion, contributing to the overall performance of machinery and equipment.

- High Speed Capability: Ball bearings can operate at high speeds, making them essential in applications where rapid rotation is required.

- Diverse Types: Ball bearings come in a variety of configurations, allowing for precise customization to meet specific application requirements.

- Durability: Depending on the material and quality, ball bearings can be highly durable and resistant to wear and tear.

- Versatility: They are used in a wide range of industries, from automotive and manufacturing to medical devices and aerospace.

Types of Ball Bearings

Ball Bearings

Deep Groove Ball Bearings

Deep groove ball bearings are particularly versatile.They are suitable for high and very high speeds, accommodate radial and axial loads in both directions.

Angular Contact Ball Bearings

Angular contact ball bearings support both radial andaxial loads through asymmetric races that house the bearing's spherical rolling elements, also called bearing balls on an angle.

Thrust Ball Bearings

Thrust ball bearings are separable bearings.The single-acting thrust ball bearing consists of a shaft washer, a housing washer and a ball set with cage.

Self-aligning Ball Bearings

Self-aligning ball bearings have two rows of balls, a common sphered raceway in the outer ring and two deep uninterrupted raceway grooves in the inner ring.They are available open or sealed.

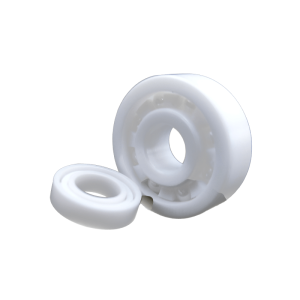

Ceramic Ball Bearings

Full ceramic ball bearings constructed entirely of ceramic material. Inner/outer races and balls are made of either Silicon Nitride (Si3N4), Zirconium Oxide (ZrO2) or Silicon carbide ( Sic ).

Thin Section Ball Bearings

Thin Section Bearings as listed below are available open, shielded or sealed. Available in a variety of standard and custom inch and metric sizes.

Stainless Steel Ball Bearings

Mainly stainless steel deep groove ball bearings. With their high resistance to corrosion, durability, and low-friction, they are an ideal choice for many industries.

Flanged Ball Bearings

Flanged bearings have a solid steel flange on the outer ring. This allows the bearing to be more easily located in a housing. The flange can also help to prevent axial movement of the bearing in the event of a thrust load on the bearing.

Applications of Ball Bearings

Automotive Industry:

- Wheel hubs: Ball bearings support vehicle wheels, allowing them to rotate smoothly.

- Transmission systems: They are used in gearboxes and differential units for power transmission.

- Electric motors: Ball bearings reduce friction, enhancing the efficiency of motors.

Manufacturing and Machinery:

- Conveyor systems: Ball bearings facilitate the movement of materials on conveyor belts.

- Industrial pumps and compressors: They are vital for smooth, low-friction operation.

- Agricultural equipment: Ball bearings support components like tractor wheels and harvesters.

Aerospace Industry:

- Aircraft landing gear: Ball bearings are used in landing gear systems for durability and reliability.

- Aircraft engines: They play a crucial role in aviation, reducing friction and ensuring efficient operation.

Medical Equipment:

- Precision instruments: Ball bearings are used in medical devices for precise motion and low noise.

Electronics:

- Computer hard drives: Ball bearings enable the smooth rotation of the drive’s platters.

- Cooling fans: They are used in fans to ensure quiet and efficient cooling.

Rail Transportation:

- Train wheels and axles: Ball bearings are integral in rail transport for smooth movement and low friction.

Power Tools:

- Electric drills and saws: Ball bearings are used in the moving parts of power tools for efficiency and durability.

Renewable Energy:

- Wind turbines: Ball bearings are employed in wind turbine systems to support the rotating blades and generator components.

Key Manufacturing Process of Ball Bearings

Raw Material Selection:

The process begins with the selection of the appropriate raw materials, typically steel, stainless steel, or ceramic, depending on the desired characteristics of the bearings.

Forging or Cold Heading:

The selected material is shaped into a rough spherical shape using forging or cold heading processes. This creates the initial blank or preform of the bearing.

Turning and Grinding:

The preform undergoes precision turning and grinding to achieve the desired outer and inner ring dimensions, as well as ball groove specifications.

Heat Treatment:

The components are heat-treated to enhance their hardness, durability, and resistance to wear. This process typically includes quenching and tempering.

Ball Production:

Steel balls are typically produced separately through a series of processes, including cold heading, flashing, grinding, and heat treatment. Ceramic balls are formed differently based on the material used.

Assembly:

The outer and inner rings, along with the ball bearings, are assembled into a bearing unit. Cages or retainers may also be added to keep the balls evenly spaced.

Lubrication:

Bearings are lubricated with grease or oil to reduce friction and ensure smooth operation. The choice of lubrication depends on the application.

Quality Control and Inspection:

Each bearing undergoes rigorous quality control and inspection to check for dimensional accuracy, smoothness, and other critical parameters. This step ensures that only high-quality bearings are shipped to customers.

Packaging and Distribution:

The finished bearings are packaged and distributed to customers, whether they are original equipment manufacturers (OEMs), distributors, or end-users.

FAQ - Frequently Asked Questions

A ball bearing is a mechanical component that uses small spherical balls to reduce friction and support radial and axial loads. It works by allowing the balls to roll between the inner and outer rings, reducing friction and enabling smooth movement.

Common types include deep groove ball bearings, angular contact ball bearings, self-aligning ball bearings, thrust ball bearings, miniature ball bearings, and more, each designed for specific applications.

Ball bearings are commonly made from steel, stainless steel, or ceramic, with each material offering specific advantages such as durability, corrosion resistance, or high-temperature capability.

Ceramic ball bearings offer reduced weight, high-temperature resistance, and superior corrosion resistance compared to steel bearings, making them ideal for demanding applications.

Selection depends on factors like load type, speed, environmental conditions, and precision requirements. Consulting with a bearing expert is often recommended.

The maximum speed depends on factors like bearing type, lubrication, and material. High-speed applications may require specific designs or ceramic bearings.

Factors include proper lubrication, load, alignment, and maintenance. Quality and material also impact bearing longevity.

Ball bearings are lubricated with grease or oil. The best choice depends on factors like speed, temperature, and load. Consult the bearing manufacturer’s recommendations.

Open bearings have no seals, shielded bearings have metal shields, and sealed bearings have rubber or plastic seals. Sealed bearings offer the best protection against contamination.

Yes, high-temperature ball bearings are available, typically made of stainless steel or ceramic, designed to withstand extreme heat.

Bearings are rated using standards such as ABEC (Annular Bearing Engineers’ Committee). Higher ABEC ratings indicate greater precision.

Load capacity varies by bearing type and size. Consult manufacturer data to determine the load capacity for a specific bearing.

Proper installation involves precise alignment, appropriate clearance, and secure fixing. Follow manufacturer guidelines and use the right tools.

Some ball bearings, like self-aligning ball bearings, can tolerate minor misalignment. However, precision bearings require proper alignment for optimal performance.

Ball bearings contribute to reduced noise and vibration by minimizing friction between moving parts.

ABEC ratings indicate bearing precision. Higher ABEC ratings offer tighter tolerances and improved performance but may not be necessary for all applications.

Regular lubrication and inspection are essential. Maintenance frequency depends on factors like load, speed, and operating conditions.

Causes of failure include inadequate lubrication, contamination, overloading, and misalignment. Preventive measures include proper maintenance and selection.

Yes, some manufacturers offer customization, including non-standard sizes, seals, lubricants, and materials tailored to specific application requirements.

Manufacturers’ websites, catalogs, and distributors typically provide technical specifications and datasheets for their products, or you can contact them directly for this information.

Installation and Maintenance of Ball Bearings

Installation

- Clean and Prepare: Ensure that the installation area is clean and free from debris or contaminants that could affect the bearing.

- Inspect Bearings: Examine the bearings for any damage or defects before installation. Do not use damaged bearings.

- Proper Handling: Handle bearings with care, using clean, dry hands or gloves to avoid transferring contaminants.

- Shaft and Housing: Ensure the shaft and housing are clean and free from burrs or nicks that could damage the bearing.

- Fit Tolerance: Pay attention to the bearing’s fit tolerance. Follow manufacturer guidelines for the appropriate fit.

- Lubrication: Lubricate the bearing according to manufacturer recommendations, using the correct type and amount of lubricant.

- Mounting: Carefully mount the bearing onto the shaft, ensuring that it is properly aligned with the housing.

- Securing: Secure the bearing in place, using the correct methods, such as set screws, locknuts, or adapter sleeves, as per the bearing design.

- Sealing: Ensure that seals or shields are properly installed to protect the bearing from contamination.

- Alignment: Precisely align the bearing to prevent misalignment issues, which can lead to premature wear.

- Tightening: Follow manufacturer torque recommendations when tightening mounting bolts or screws.

Maintenance:

- Regular Inspection: Periodically inspect the bearings for signs of wear, overheating, or unusual noise during operation.

- Lubrication Maintenance: Maintain proper lubrication according to the manufacturer’s guidelines. Re-grease or re-oil as needed.

- Temperature Monitoring: Keep an eye on operating temperatures; an increase may indicate issues with lubrication or alignment.

- Seal and Shield Inspection: Check seals and shields for damage and replace them if they are compromised.

- Vibration Analysis: Utilize vibration analysis tools to detect irregular vibrations that may signify problems with the bearing.

- Re-greasing: Re-grease the bearings at regular intervals to maintain proper lubrication and prevent overheating.

- Cleaning: Clean the surrounding area to prevent contamination from entering the bearing.

- Replacement: When a bearing shows signs of significant wear or damage, replace it promptly to avoid equipment failure.

- Documentation: Maintain records of installation and maintenance procedures, including dates and any observed issues.

- Training: Ensure that personnel responsible for installation and maintenance are trained and knowledgeable about best practices.

Related Posts

Salt Bath Heat Treatment Process: Precision Forging Of Metallic Materials

Table of Contents Categories Salt Bath Heat Treatment Process: Precision...

Read MoreThe Versatility And Impact Of Ball Bearings

Categories The Versatility And Impact Of Ball Bearings Table of...

Read MoreIn-Depth Comparison: Wheel vs Hub Bearings

In-Depth Comparison: Wheel vs Hub Bearings Table of Contents Introduction...

Read MorePrecision Engineering with Angular Bearings

Precision Engineering with Angular Bearings Table of Contents The Crucial...

Read More