Pillow Block Bearings

Table of Contents

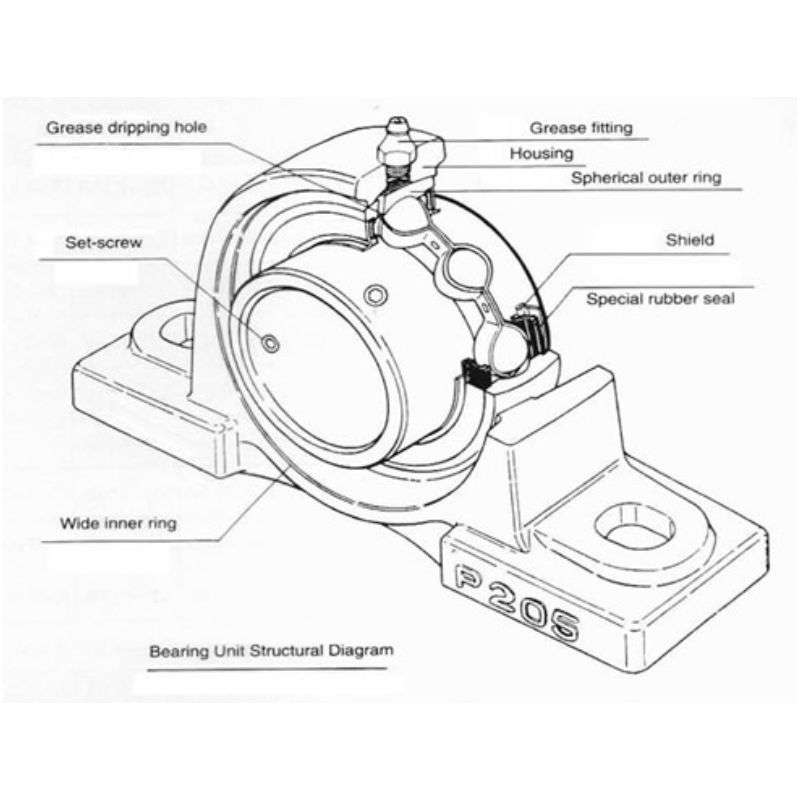

Definition of Pillow Block Bearings

A pillow block bearing (or plummer block) is a pedestal used to provide support for a rotating shaft with the help of compatible bearings and various accessories. The assembly consists of a mounting block which houses a bearing.

FHD Bearings is an ISO 9001:2015 certified manufacturing company. The enterprise specializes in producing various series of pillow block bearings with many different sizes available to meet customers’ needs.

Materials of Pillow Block Bearings

-Cast iron is a popular choice for pillow block housings due to its excellent durability and resistance to wear and tear. It can withstand heavy loads and is often used in industrial settings.

–FHD Bearing Company believes that the advantages of selecting materials for cast iron pillow block bearings lie in their outstanding strength and durability, making them ideal for heavy machinery and industrial equipment to ensure solid support and reliable performance.

Ductile Iron

– Ductile iron, also known as nodular cast iron, is similar to cast iron but offers higher tensile strength and toughness. This material is particularly useful when high loads and shock resistance are required.

–The advantages of selecting materials for ductile iron pillow block bearings are their excellent toughness and wear resistance for applications with high loads and shock loads.

Stainless Steel

– Stainless steel pillow block bearings are ideal for applications where corrosion resistance is critical, such as food processing or pharmaceutical industries. They offer longevity and hygiene benefits.

–Stainless steel pillow block bearings are selected for their excellent corrosion resistance, which makes them particularly suitable for applications requiring hygiene and long-term durability, such as in the food processing or pharmaceutical industries.

Thermoplastic

– Thermoplastic pillow block bearings are lightweight, corrosion-resistant, and suitable for applications in wet or chemically aggressive environments.

Plastic

– Some pillow block housings are made from plastic materials, such as thermoplastic or composite materials. These are lightweight, corrosion-resistant, and often used in applications where sanitation and chemical resistance are essential.

– Advantages of material selection for plastic pillow block bearings include light weight, corrosion resistance and suitability for wet or chemically aggressive environments.

– In certain cases, pillow block housings may be made from steel. This is common in heavy-duty industrial applications, where the housing needs to withstand extreme loads and environmental conditions.

-For FHD Bearing Company, the advantages of steel pillow block bearings selection are their superior strength and durability for applications with high loads and harsh environments.

– Cast steel provides a balance between strength and ductility. It is used in applications where high load capacity is required.

Features of Pillow Block Bearings

- Housing Design

Pillow block bearings consist of a housing that provides support and stability to the bearing. The housing is designed to accommodate the insert bearing securely.

- Insert Bearings

These bearings include an inner bearing (insert bearing) that can be easily replaced. This allows for cost-effective maintenance and versatility in choosing the appropriate bearing for the application.

- Load Support

Pillow block bearings offer effective support for both radial and axial loads. This feature is crucial for ensuring smooth and efficient shaft rotation.

- Versatility

They come in various configurations, sizes, and materials, making them versatile and suitable for a wide range of industrial applications.

- Ease of Installation

Mounting pillow block bearings is relatively straightforward, and they are designed for easy installation, which is advantageous for businesses in terms of time and labor efficiency.

- Customization

Many manufacturers offer customization options, allowing businesses to tailor these bearings to their specific requirements. This aligns with your business model of offering various types of customized bearings.

- Application Diversity

Pillow block bearings find applications in diverse industries, including agriculture, manufacturing, mining, and more. They are commonly used in conveyor systems, fans, and various machinery.

- Material Options

Pillow block bearings can be made from various materials, including cast iron, ductile iron, plastic, steel, and stainless steel, allowing for material selection based on the application’s needs.

- Corrosion Resistance

Depending on the material chosen, they can provide resistance to corrosion, which is crucial for applications in harsh or chemically aggressive environments.

- Maintenance

These bearings are generally easy to maintain, with lubrication being a key factor in their longevity and efficient operation.

Advantages of Pillow Block Bearings

- Stability and Support: Pillow block bearings provide stable support for rotating shafts, ensuring smooth and efficient operation.

- Versatility: They come in various configurations, sizes, and materials, making them adaptable to a wide range of applications and industries.

- Easy Installation: Mounting pillow block bearings is relatively straightforward, simplifying the installation process and reducing downtime.

- Customization: Many manufacturers offer customization options, allowing businesses to tailor these bearings to specific application requirements.

- Load Handling: Pillow block bearings are capable of handling both radial and axial loads, making them versatile for different load types.

- Material Options: These bearings can be made from materials like cast iron, ductile iron, plastic, steel, and stainless steel, allowing for material selection based on environmental and load conditions.

- Wide Market Availability: Pillow block bearings are readily available in the market, making them a convenient choice for businesses.

- Reliability: These bearings are known for their reliable performance, contributing to the overall efficiency of machinery and equipment.

- Application Diversity: Pillow block bearings are suitable for a wide range of applications, including conveyor systems, fans, agricultural machinery, and more.

- Corrosion Resistance: Depending on the material chosen, pillow block bearings can provide resistance to corrosion, ensuring longevity in harsh or corrosive environments.

- Maintenance-Friendly: They are generally easy to maintain, and routine lubrication is key to their long-term performance.

- Cost-Effective: The ability to replace the inner bearing (insert bearing) rather than the entire housing makes maintenance cost-effective.

Taxonomy of Pillow Block Bearings

Mounted Bearing Units

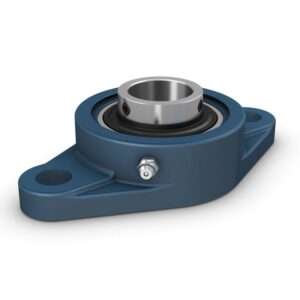

Pillow Block Ball Bearing

Bearing Pillow Block Units feature Cast lron, Malleable lron, or Pressed Steel Housings and either Set Screw Locking, Eccentric Collar Locking, Accu-Loca Concentric Collar Locking, Adapter Sleeve

Set Screw Locking Pillow Plock Bearing

Cast Iron, Malleable lron or Pressed Steel Two-Bolt Flange Housings with Set Screw Locking Bearing Inserts

Four-Bolt Flange Bearing Units

The four-bolt flange bearing unit is a bearing unit with four bolt holes for mounting and securing to mechanical equipment to provide stabilizing support.

Normal Duty Set Screw Bearing Insert

Set Screw Bearing Inserts Pillow Block Bearings are specially designed pillow block bearings with embedded screws or fixtures that provide additional stability and support for applications requiring vibration and twist mitigation.

Applications of Pillow Block Bearings

- Conveyor Systems: Pillow block bearings are commonly used in conveyor belts to support and guide the movement of materials, ensuring smooth and efficient transportation.

- Agricultural Machinery: They play a crucial role in agricultural equipment, such as tractors, plows, and combine harvesters, where they support rotating shafts and reduce friction.

- Manufacturing Equipment: In manufacturing industries, pillow block bearings are used in machinery like CNC machines, lathes, and mills to enable precise and consistent operation.

- Mining Equipment: These bearings are employed in mining equipment, including crushers, screens, and conveyor systems, where they withstand heavy loads and harsh conditions.

- Industrial Fans: Pillow block bearings are used in industrial fans to support the fan shaft and ensure efficient air circulation.

- Pumps: They are utilized in various types of pumps, including centrifugal and reciprocating pumps, to facilitate fluid transfer.

- Agricultural Machinery: Pillow block bearings are essential in agricultural machinery, such as irrigation pumps and grain augers, to ensure reliable operation in farming applications.

- Construction Equipment: In construction machinery like concrete mixers and cranes, these bearings help manage the loads and rotations of key components.

- Food Processing: Stainless steel pillow block bearings are used in food processing equipment to maintain hygiene standards and prevent contamination.

- Automotive Industry: They are found in automotive applications, including vehicle suspension systems and drive components.

Key Manufacturing Processes For Pillow Block Bearing

Bearing Component Production:

- Outer Ring: The outer ring is typically made from materials like steel or cast iron. It is produced using processes such as turning, grinding, or casting to achieve the required dimensions and precision.

- Inner Ring: Similar to the outer ring, the inner ring is manufactured with precision grinding, turning, or casting operations. It must have precise dimensions to fit the shaft properly.

- Ball Bearings: Steel balls are manufactured with high precision to ensure uniform size and shape, typically through processes like cold heading or grinding.

Heat Treatment:

- All major components, including the rings and ball bearings, undergo heat treatment processes like quenching and tempering to enhance their hardness and durability.

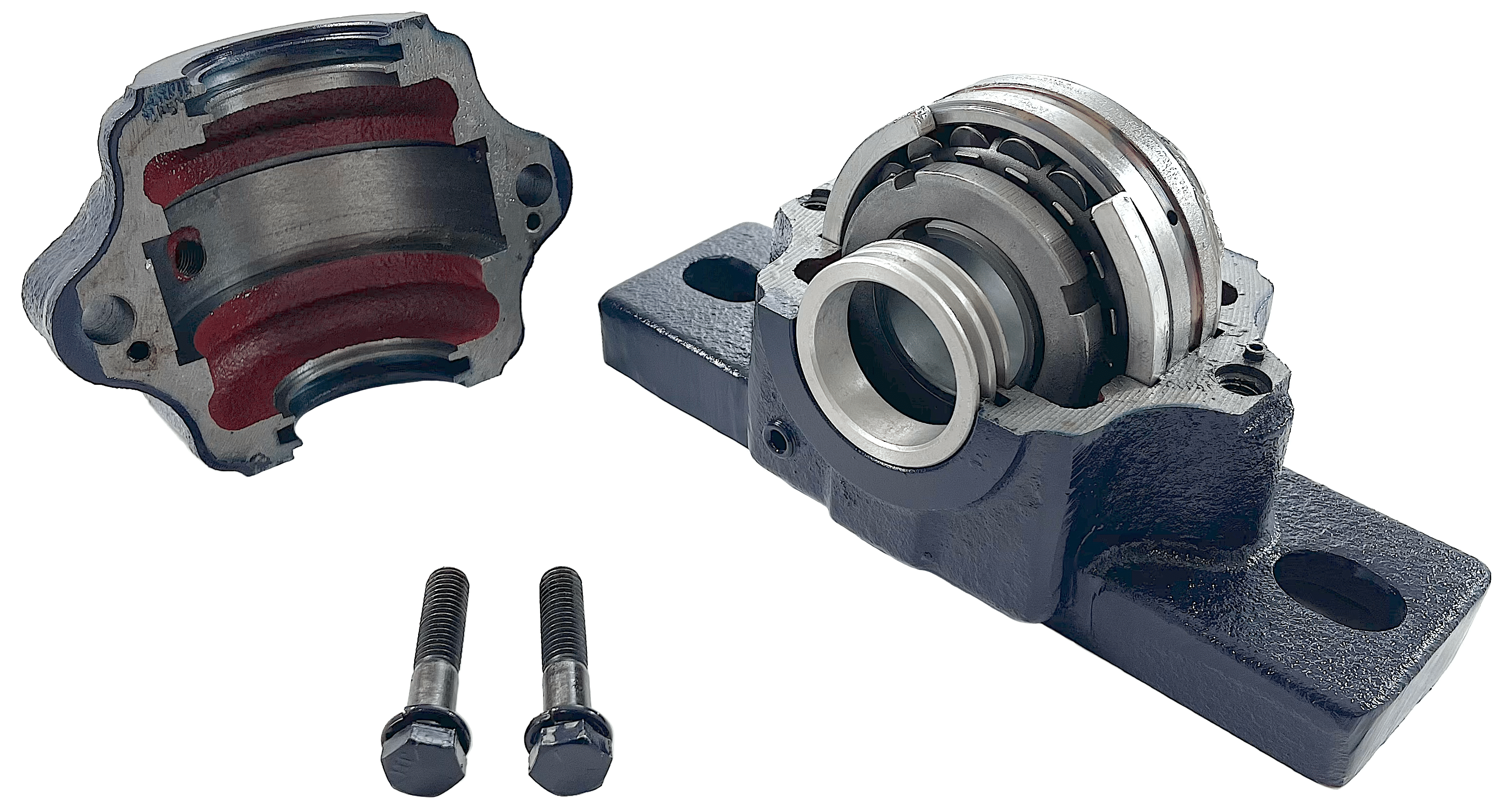

Assembly:

- The ball bearings are assembled between the inner and outer rings. The assembly process involves ensuring precise alignment and adequate clearance for smooth rotation.

Sealing:

- Many pillow block bearings have integrated seals to protect against contamination and retain lubrication. Seals are typically made from rubber or other suitable materials and are carefully installed.

Lubrication:

- Proper lubrication is crucial for the bearings’ smooth operation. The bearing is filled with the appropriate lubricant, and methods like oil bath or grease packing are used to ensure adequate lubrication.

Mounting in Housing:

- The assembled bearing is mounted in the housing (pillow block). The housing is often made from materials like cast iron, ductile iron, or thermoplastic, and it’s manufactured using casting, machining, or injection molding processes.

Alignment and Testing:

- The bearing is aligned within the housing to ensure proper fit and clearances. Quality control and testing processes, including runout and noise testing, are performed to check for any defects.

Customization:

- Depending on customer requirements, the bearing may undergo customization, such as special coatings, seals, or specific tolerances to meet unique application needs.

Packaging:

- Once the bearing unit is assembled and tested, it is packaged and prepared for shipping or distribution. Proper packaging ensures the product arrives in good condition.

Quality Control:

- Rigorous quality control measures are in place throughout the manufacturing process to verify the dimensional accuracy, surface finish, and overall performance of the bearings.

FAQ - Frequently Asked Questions

A pillow block bearing, also known as a plummer block bearing, is a mounted bearing unit that provides support and stability to rotating shafts. It consists of a housing and an inner bearing (insert bearing).

Pillow block bearings are used in a wide range of applications, including conveyor systems, agricultural machinery, manufacturing equipment, mining equipment, industrial fans, and more.

Pillow block bearings can be made from materials like cast iron, ductile iron, steel, stainless steel, or thermoplastic, depending on the application’s requirements.

Installation typically involves securing the housing to a mounting surface and ensuring proper alignment and lubrication. It’s essential to follow the manufacturer’s guidelines for installation.

No, regular maintenance is necessary. Lubrication is key to their longevity and efficient operation. Periodic inspections and lubrication are recommended to prevent wear and damage.

Many manufacturers offer customization options, allowing you to tailor the bearings to your specific requirements, including special coatings, seals, or specific tolerances.

Key advantages include stability, versatility, ease of installation, customization options, load-bearing capacity, and suitability for various applications.

Selecting the right pillow block bearing involves considering factors such as load type, speed, environmental conditions, and the material of the bearing, among others. It’s advisable to consult with bearing experts or manufacturers for guidance.

A pillow block bearing is mounted in a housing, while a flange bearing is directly bolted to the mounting surface. Pillow block bearings offer more support and stability.

Pillow block bearings are available from various suppliers, including manufacturers, distributors, and online marketplaces. Your business, FHD Bearings, specializes in offering top-quality pillow block bearings for B2B wholesale and retail customers.

Installation and Maintenance

Pillow Block Bearings Installation

- Preparation:Ensure a clean and well-lit work area.Gather all necessary tools and equipment, including a torque wrench, lubricants, and safety gear.

Inspect Bearings:Examine the pillow block bearings and their components for any visible damage or defects before installation.

Mounting Surface:Ensure the mounting surface is clean, level, and capable of supporting the pillow block unit.

Alignment:Properly align the housing with the mounting surface and the shaft. Misalignment can lead to premature wear.

Lubrication:Apply the appropriate lubricant to the bearing and the inner race of the insert bearing. Be sure to use the manufacturer’s recommended lubricant.

Insert Bearing:Carefully slide the insert bearing into the housing. Make sure it’s securely seated and properly aligned with the shaft.

Secure Housing:Bolt or fasten the housing to the mounting surface using the provided bolt holes. Torque the bolts to the manufacturer’s specifications.

Set Screws or Locking Collars:If your pillow block bearing uses set screws or locking collars to secure the shaft, make sure they are tightened according to the manufacturer’s guidelines.

Lubrication System:Check if your system has a lubrication system. If so, ensure it’s properly connected and functioning.

Maintenance:

Regular Lubrication:Establish a lubrication schedule and follow it diligently. Lubricate the bearing at recommended intervals to prevent excessive wear.

Visual Inspection:Regularly inspect the bearing for signs of wear, corrosion, or contamination. If you notice any issues, address them promptly.

Re-tightening Set Screws or Locking Collars:If your bearing uses set screws or locking collars, periodically check and re-tighten them to maintain proper shaft attachment.

Environmental Protection:Ensure that the bearing and housing are adequately sealed or protected against contaminants, moisture, and corrosive substances.

Temperature Control:Monitor the operating temperature of the bearing. Excessive heat can lead to premature failure. Adequate cooling may be necessary in high-temperature environments.

Vibration Analysis:Periodically perform vibration analysis to detect any anomalies that could indicate impending issues.

Replace Seals:If the seals become damaged or worn, replace them promptly to maintain effective protection against contamination.

Re-greasing:At specified intervals, clean and re-grease the bearing. Ensure the old grease is fully purged before applying fresh lubricant.

Record-keeping:Maintain a detailed maintenance log, including dates of lubrication, inspections, and any repairs or replacements.

Training:Train your maintenance personnel to follow manufacturer guidelines and best practices for pillow block bearing maintenance.