Plain Bearings

Table of Contents

Definition of Plain Bearings

Plain bearings, also known as bushings or sleeve bearings, are simple yet crucial components in machinery. They consist of a cylindrical-shaped sleeve, often made of metal, that provides a surface for sliding or rotating motion. These bearings operate without rolling elements and are lubricated to reduce friction between the sliding surfaces. Plain bearings find applications in various industries, offering reliable support and minimal friction in diverse mechanical systems.

FHD Bearings is an ISO 9001:2015 certified manufacturing company with a wide range of products in stock to ensure your diverse needs are met.

Materials of Plain Bearings

–The plain bearings have a steel/PTFE sintered bronze contact surface combination and are maintenance-free. The sliding surfaces have to be externally protected from contaminants. These bearings are also available with a wider inner ring and a larger outside diameter (suffix GEH), which enable higher load ratings and larger tilt angles.

– FHD uses steel plain bearings because steel has excellent strength, wear resistance and thermal conductivity for large loads and high speeds.

– Thrust spherical plain bearings are designed to accommodate axial and combined radial and axial loads. This specific design includes a steel/PTFE FRP sliding contact surface combination that is maintenance-free. However, relubrication, which can be applied from both sides, can extend bearing service life.

– FHD’s PTFE plain bearings have excellent friction and chemical resistance and are suitable for applications requiring low friction and high chemical stability.

– POM composite strips are suitable for linear, rotating and oscillating movements, and can accommodate heavy loads. After an initial grease fill, they are optimized for minimal maintenance under tough operating conditions. Pockets in the sliding surface serve as grease reservoirs. Relubrication can extend bearing service life considerably.

– FHD’s plain bearings using polyformaldehyde composites offer excellent wear resistance and self-lubrication for high-load, high-speed industrial applications.

–PTFE polyamide straight (cylindrical) bushings are suitable for oscillating, rotary and linear movements and can withstand radial loads. Despite their thin-walled design, they are wear-resistant and can withstand moderate loads.

– FHD uses PTFE polyamide because of its excellent friction resistance and chemical stability for industrial applications requiring high performance, low friction and corrosion resistance.

– solid bronze straight (cylindrical) bushings are suitable for oscillating, rotating and linear movements, and can accommodate radial loads. They are designed for a wide variety of operating conditions and applications in tough environments.

– FHD’s sliding bearings made of bronze have good wear resistance and thermal conductivity, and are suitable for use in high-load, high-temperature environments, providing reliable performance.

– PTFE composite flanged bushings are suitable for oscillating, rotating and linear movements, and can accommodate radial loads as well as axial loads in one direction. Despite their thin-walled design, they can accommodate heavy loads. They also provide good heat dissipation, therefore enabling relatively high sliding velocities.

– FHD’s plain bearings with PTFE composites offer excellent friction and wear resistance for high performance applications requiring low friction and long life.

Features of Plain Bearings

- Noiseless: Because there are no rolling elements, plain bearings generally produce low noise during operation, making them suitable for applications that are sensitive to noise requirements.

- Self-lubricating: Sliding bearings are able to form a lubricating film through the lubricant, providing a self-lubricating effect, reducing friction and wear, and extending service life.

- Large load carrying capacity: Sliding bearings are usually able to withstand large radial loads and axial loads, suitable for high load conditions.

- Strong adaptability: for the working environment is less demanding, especially in the more pollutant conditions, plain bearings can show better adaptability.

- Simple structure: Compared with rolling bearings, the structure of plain bearings is relatively simple, easy to design, manufacture and maintain.

- Relatively low cost: Plain bearings are relatively inexpensive to manufacture and are suitable for cost-sensitive applications.

Advantages of Plain Bearings

- Shock Resistance: Slide bearings typically have better shock resistance when subjected to shock loads, which helps prevent damage due to external shocks.

- Low Starting Friction: Plain bearings typically have low starting friction, which means less force is required during startup, helping to reduce power loss.

- Large size range: Slide bearings can be manufactured in a wide range of sizes and shapes to suit the needs of different industrial applications.

- Simplified lubrication systems: Because they are self-lubricating, plain bearings simplify lubrication systems and reduce the complexity of lubrication installations.

Taxonomy of Plain Bearings

Spherical Plain Bearings

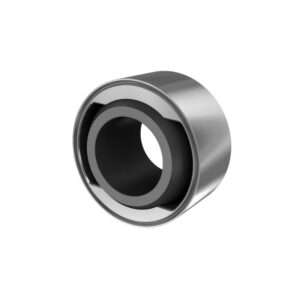

Radial Spherical Plain Bearings

Radial spherical plain bearings have an inner ring witha sphered convex outside diameter and an outer ringwith a correspondingly sphered but concave insidesurface. Their design makes them particularly suitablefor bearing arrangements where alignment.

Angular Contact Spherical Plain Bearings

As their name implies, the sliding contact surfaces of angular contact spherical plain bearings are sphericalin shape and inclined at an angle to the bearing axis.Consequently, these bearings are wellsuited for accommodating combined (radial and axial).

Thrust Spherical Plain Bearings

Thrust spherical plain bearings have a convex spherical surface on the shaft washer and acorresponding concave spherical surface in the housing washer.They are intended to accommodate axial loads primarily but can also accommodate.

Aerospace Spherical Bearings

Aerospace spherical plain bearings have excellent adaptability to high temperature and high load environments, ensuring reliable operation and long-lasting performance.

Rod Ends

Female Thread

Rod ends are also available for specific applicationsfor example, where a rod end is attached to the end ofa piston rod or at the base of a hydraulic cylinder. Forthese applications, manufactures rod ends with aslotted shank and a compressible threaded section .

Male Thread

Rod ends are also available for specific applicationsfor example, where a rod end is attached to the end ofa piston rod or at the base of a hydraulic cylinder. For these applications,manufactures rod ends with aslotted shank and a compressible threaded section.

Welding Shank

Rod ends are also available for specific applicationsfor example. where a rod end is attached to the end ofa piston rod or at the base of a hydraulic cylinder. For these applications,manufactures rod ends with aslotted shank and a compressible threaded section.

Bushings

Sintered Bronze Straight Bushing

Sintered bronze straight (cylindrical) bushings are suitable for rotating, oscillating and linear movements, and can accommodate radial loads.Sintered bronze bushings are self-lubricating and maintenance-free. They consist of a porous bronze matrix that is impregnated with mineral oil.

PTFE Composite Straight Bushing

PTFE composite straight (cylindrical) bushings are suitable for oscillating, rotating and linear movements, and can accommodate radial loads. Despite their thin-walled design, they can accommodate heavy loads.

Solid Bronze Straight Bushing

Solid bronze straight (cylindrical) bushings are suitable for oscillating, rotating and linear movements, and can accommodate radial loads. They are designed for a wide variety of operating conditions and applications in tough environments.

Solid Bronze Flanged Bushing

Solid bronze flanged bushings are suitable for oscillating, rotating and linear movements, and can accommodate radial loads as well as axial loads in one direction.

PTFE Composite Flanged Bushing

PTFE composite flanged bushings are suitable for oscillating, rotating and linear movements, and can accommodate radial loads as well as axial loads in one direction. Despite their thin-walled design, they can accommodate heavy loads.

Sintered Bronze Flanged Bushing

Sintered bronze flanged bushings are suitable for rotating, oscillating and linear movements, and can accommodate radial loads as well as axial loads in one direction.Sintered bronze bushings are self-lubricating and maintenance-free. They consist of a porous bronze matrix that is impregnated with mineral oil.

POM Composite Straight Bushing

POM composite straight (cylindrical) bushings are bearing sleeves with excellent wear resistance and low friction characteristics, widely used in construction machinery and motion systems.

PTFE Polyamide Flanged Bushing

PTFE polyamide flange bushings are a corrosion- and temperature-resistant lubricant material commonly used in flange connections to reduce friction and improve wear resistance.

PTFE Polyamide Straight Bushing

PTFE polyamide straight bushing is a corrosion-resistant, high-temperature resistant bearing sleeve used to reduce friction and improve lubrication

Strips

POM Composite Strip

POM composite strips are suitable for linear, rotating and oscillating movements, and can accommodate heavy loads. After an initial grease fill, they are optimized for minimal maintenance under tough operating conditions.

PTFE Composite Strip

PTFE composite strips are suitable for linear, rotating and oscillating movements, and can accommodate heavy loads. The material provides good heat dissipation, therefore enabling relatively high sliding velocities.

Thrust Washers

PTFE Composite Thrust Washer

PTFE composite thrust washers are suitable for rotating and oscillating movements, and can accommodate heavy axial loads. They have as standard a hole to take a pin or screw to prevent the washers from rotating on their seat.

Applications of Plain Bearings

- Machinery manufacturing: Plain bearings are widely used in machinery and equipment, such as industrial machinery, machine tools and transmission systems in production lines.

- Automobile industry: In automobile engines, transmissions and suspension systems and other parts, plain bearings are widely used in various vehicles.

- Wind power: Sliding bearings are used in the main shafts and rotating blades of wind turbines to withstand the high loads imposed on the rotor by the wind.

- Aerospace: In the aerospace field, plain bearings are used in aircraft landing gear, engines and other critical systems.

- Railroad transportation: Sliding bearings are used in the wheels, drivelines and suspensions of railroad vehicles to ensure smooth operation.

- Power industry: used in power station generator sets, turbines and pumps and other equipment, plain bearings play the role of support and transmission.

- Marine engineering: in the marine platform, ships and marine equipment, plain bearings bear important support and transmission tasks.

- Oil and gas: Plain bearings are used in oil exploration, extraction and transmission systems to withstand high temperature and pressure environments.

- Heavy Machinery: In heavy machinery such as excavators, loaders and bulldozers, plain bearings provide high load capacity and reliability.

- Medical Equipment: In the medical industry, plain bearings are used in equipment such as X-ray machines and CT scanners to ensure smooth operation and accurate imaging.

Key Manufacturing Process of Plain Bearings

Raw Material Preparation

Selection of wear- and corrosion-resistant materials, such as alloys or composites.

Preliminary machining

erform preliminary machining, including forging and heat treatment, to obtain the initial shape in accordance with the design requirements.

Surface treatment

surface treatment, such as coating, nitriding, in order to improve the surface hardness and wear resistance.

Assembling

Assemble the components into the plain bearings to ensure proper mounting and good fit.

Quality Control & Testing

Perform quality control and use test equipment to verify bearing parameters to ensure compliance with specifications.

FAQ - Frequently Asked Questions

A plain bearing, also known as a sleeve bearing or bushing, is a type of bearing that operates with sliding contact between its components.

Common materials include bronze, brass, steel, and various self-lubricating materials like PTFE (polytetrafluoroethylene) or composite materials.

Unlike rolling bearings that use balls or rollers, plain bearings operate with sliding surfaces, providing lower friction but requiring lubrication.

Plain bearings are known for their simplicity, cost-effectiveness, and suitability for high loads and low-speed applications.

Plain bearings require proper lubrication for optimal performance. Lubrication methods include oiling, greasing, or utilizing self-lubricating materials.

Plain bearings find applications in various industries, including automotive, aerospace, industrial machinery, and home appliances.

Regular maintenance, proper lubrication, and monitoring operating conditions can contribute to extending the lifespan of plain bearings.

Some self-lubricating plain bearings can operate with minimal or no external lubrication, relying on internal materials that release lubricants during operation.

Common causes of plain bearing failure include insufficient lubrication, contamination, misalignment, excessive loads, and improper installation.

Depending on the material used, some plain bearings can withstand high temperatures. Materials like bronze or special alloys may be chosen for elevated temperature environments.

Installation and Maintenance

Installation

- Preliminary: Prior to mounting, ensure that the work area is clean and check the condition of the bearings, journals and related components.

- Lubrication: Apply an appropriate amount of lubricant to the bearing surfaces to ensure that the bearings slide smoothly during installation.

- Bearing Positioning: Position the bearing accurately on the journal to ensure that the bearing is oriented correctly.

- Bearing Installation: Gently slide the bearing into the journal to ensure that the bearing is not damaged during installation.

- Heat the bearing: For larger bearings, it may be necessary to heat the bearing or cool the journal to make it easier to install.

- Use tools: Use appropriate tools, such as a mounting sleeve or hydraulic press, to assist in the mounting of the bearing and to ensure that the force is applied evenly.

- Check bearing position: Ensure that the bearing is correctly mounted in the designed position and should not be loose or tilted.

- Fixing bearings: Use lock nuts or other fixing devices according to the design requirements to ensure that the bearings remain stable during operation.

- Check Rotation: After installation, manually rotate the bearings to ensure that they rotate freely and that there is no abnormal noise or sticking.

- Final inspection: Perform a final inspection to ensure that the bearings are properly installed, well lubricated, and free of abnormalities. If necessary, record the date of installation and related information.

Maintenance:

- Regular lubrication: Ensure that the bearings are regularly filled with the proper amount of lubricant to minimize friction and extend service life.

- Cleaning and Maintenance: Regularly clean the bearings to prevent dirt buildup and to improve the efficiency of the bearings.

- Monitor Temperature and Vibration: Regularly monitor the temperature and vibration of the bearings. Abnormalities may be a sign of a problem and require timely maintenance.

- Clearance check: Regularly check the clearance of the bearings to ensure that it is within the specified range and adjust it if necessary.

- Lubricant Replacement: Replace the lubricant periodically to ensure that the bearings are always adequately lubricated.

- Seal Check: Check bearing seals to ensure good sealing and to prevent contaminants from entering the bearing.