Self-aligning Ball Bearings

Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

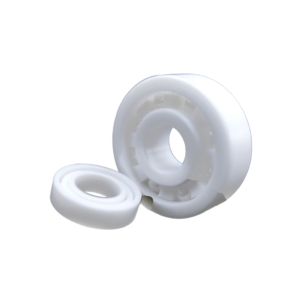

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Definition Of Self-aligning Ball Bearings

Self-aligning ball bearings are characterized by a spherical raceway in the outer ring, and the center of curvature of this raceway is precisely matched with the bearing center. This design facilitates unrestricted rotation of the inner ring, balls, and cage around the bearing center, allowing the bearing to maintain proper alignment during operation.

FHD Bearings is an ISO 9001:2015 certified manufacturing enterprise .Our company has a wide range of products in stock covering a wide range of areas to ensure that we are able to meet the diverse needs of our customers. We offer a wide selection of both models and specifications to ensure that our customers are able to quickly obtain the products they need and meet their specific engineering and business requirements.

Materials Of Self-aligning Ball Bearings

-The steel quality has good wear resistance, which is essential for the bearings to maintain stability and reduce wear during long periods of operation, especially at high speeds.

-The main factors for FHD to choose steel as self-aligning ball bearings are its superior strength, hardness and abrasion resistance to meet the demand for reliability under complex operating conditions such as high loads and high speeds.

-Stainless steel material is corrosion resistant and suitable for wet or corrosive environments

-The main factor in FHD’s choice of stainless steel for self-aligning ball bearings is its excellent resistance to corrosion for wet or corrosive environments, increasing the durability of the bearings.

-Self-aligning ball bearings made of ceramic offer superior wear and corrosion resistance, providing longer life and higher performance.

Polyurethane

The polyurethane material has good abrasion resistance and is suitable for high-speed operating environments.

Rubber

Rubber material has good elasticity and sealing, effective dustproof and waterproof.

Features Of Self-aligning Ball Bearings

1.Self-adaptation: Able to automatically adjust the angular misalignment between the shaft and the bearing to adapt to different working conditions.

2.Multi-directional loads: Able to withstand axial and radial loads, providing greater load carrying capacity.

3.High-speed operation: Reduced friction and self-aligning features make it suitable for high-speed operation.

4.Simplified mounting: Easier mounting than other bearings, reducing engineer’s skill requirements.

5.Low noise: Reduced friction results in relatively low noise during operation.

6.Anti-vibration and shock: Good anti-vibration and anti-shock performance to ensure stable operation in vibration environments.

7.High-temperature adaptability: for high-temperature environments, self-aligning ball bearings made of appropriate materials can maintain stability.

8.Reduce maintenance costs: Designed to reduce friction and wear, reducing the need for lubrication and maintenance, reducing maintenance costs.

9.Improved equipment accuracy: Improved operating accuracy is achieved through angular misalignment compensation and multi-directional load support.

Advantages Of Self-aligning Ball Bearings

- Rigidity Advantage: High bearing rigidity helps to reduce equipment vibration and deformation and improve system stability.

- Reduction of the impact of installation errors: strong angular misalignment ability, can reduce the abnormal operation caused by installation errors.

- Compact axial length: Compact structure, suitable for designs with limited space, helps to simplify the mechanical layout.

- Lightweight design: Flexibility in material selection and structural design enables the bearings to be lightweight, which helps to improve the overall efficiency of the equipment.

- Long life: Due to self-adaptation and low friction, bearing life can be extended, reducing the frequency of replacement and maintenance.

Applications Of Self-aligning Ball Bearings

- Mechanical manufacturing industry: in a variety of mechanical equipment, such as wind turbines, pumps, fans, etc., to provide reliable multi-directional load support.

- Automotive industry: used in automotive transmission systems, steering wheel bearings, engine parts, etc., to adapt to high-speed and multi-directional load requirements.

- Electric power industry: in the motor, generator and other equipment, to deal with complex operating conditions, to provide stable support.

- Iron and steel industry: for rolling mills, continuous casting machines and other equipment, to cope with the requirements of high load and high-speed operation.

- Metallurgical industry: Used in iron furnaces, rolling mills, etc., with good adaptability to high temperatures and high-load environments.

- Food and beverage industry: in conveying equipment, packaging machinery, etc., to meet the health standards and high-speed operation requirements.

- Textile industry: used in spinning machines, looms, etc., with high-speed and multi-directional load handling capabilities.

- Medical Equipment: Reliable bearing support in medical scanners, surgical equipment and more.

- Aerospace: In aircraft engines, gyroscopes and other equipment to cope with high speeds and complex operating conditions.

- Electronic equipment: Stable running support in equipment such as printing presses and photocopiers.

Key Manufacturing Process of Self-aligning Ball Bearings

Material Selection: Selection of appropriate materials, such as high-carbon chrome steel (GCr15), stainless steel, ceramics, etc., according to the environment and requirements of the use of bearings.

Material pre-treatment: Heat treatment, surface treatment and other pre-treatment processes for selected materials to improve hardness, strength and corrosion resistance.

Cold forming: through the pressure processing or cold forging and other processes will be metal billet cold formed into a basic shape, the formation of the shape of the bearing.

Heat treatment: heat treatment of bearing parts, such as quenching, tempering, etc., in order to adjust the material properties, improve the hardness and wear resistance of bearings.

Precision machining: Use lathe, grinder and other precision machinery and equipment to carry out fine machining to ensure the geometry and surface quality of the bearing.

Assembly: assemble the parts according to the design requirements, including bearing ring, rolling body, cage and other components.

Lubrication: Add appropriate grease or lubricant inside the bearing to ensure low friction and smooth operation.

Sealing: If necessary, add seals around the bearing to prevent dust, impurities, etc. from entering the bearing.

Quality Inspection: Conduct strict quality inspection, including appearance inspection, size measurement, wear resistance test, etc., to ensure that the bearings meet the design standards.

Packing: Pack the finished bearings to prevent damage during transportation and storage.

FAQ - Frequently Asked Questions

The special structural design inside the bearing enables it to automatically adjust the angular misalignment between the shaft and the bearing to adapt to different working conditions.

Widely used in machinery manufacturing, automobile industry, electric power industry, metallurgical industry, food and beverage industry and many other fields.

During the mounting process, we need to make sure that the bearings are centered to reduce the mounting error, and at the same time, we need to use appropriate lubricant and pay attention to the direction of the bearing rings.

The life depends on the working conditions, load, speed and other factors, correct maintenance and proper lubrication can prolong the bearing life.

Depending on the operating environment, some bearings may require additional seals to prevent dust, impurities, etc. from entering the bearing interior.

The temperature range depends on the material and the lubrication method, and can generally accommodate operating temperatures from -40°C to +150°C. The temperature range of self-aligning ball bearings depends on the material and the lubrication method.

By monitoring indicators such as vibration, noise and temperature rise, as well as regular visual inspections, it is possible to determine whether a bearing needs to be replaced.

Self-aligning ball bearings have self-adapting and multi-directional loading capability, which makes them more suitable for complex working conditions compared with other bearings.

Moderate preload helps to improve the rigidity and running accuracy of bearings, but excessive preload may lead to premature wear of bearings.

Lubrication methods include oil lubrication and grease lubrication, and the choice is based on working conditions, speed and temperature and other factors for appropriate lubrication.

Installation and Maintenance

Installation

- Preparation: Make sure the working environment is clean and check whether the bearings and related parts are in good condition.

- Bearing lubrication: Apply appropriate amount of grease or lubricating oil on the inner and outer ring surfaces of the bearing to ensure adequate lubrication.

- Bearing mounting:Slide the bearing gently onto the shaft to ensure that the bearing surface is not damaged.

Pay attention to the direction of the bearing to avoid reverse installation.

- Fixing the bearings: Use suitable fasteners to install the bearings on the shaft and make sure that the bearings can rotate freely.

- Position marking: Mark the relative positions of the bearing and related parts for subsequent maintenance.

- Final check: Check whether the bearing is firmly installed and ensure that the bearing can rotate freely.

Maintenance

- Regular Lubrication: According to the working conditions, check the lubrication status of the bearings regularly and add or replace grease or lubricant in time.

- Temperature monitoring: Regularly monitor the working temperature of the bearings, abnormal elevation may be insufficient lubrication or other problems indication.

- Clean environment: Keep the working environment clean to prevent dust and impurities from entering the bearings and affecting normal operation.

- Vibration Detection: Regularly use vibration instruments to detect the vibration level of the bearing, abnormal vibration may indicate that the bearing has problems.

- Regularly check the fasteners: Check the fasteners of the bearing installation to ensure that they are stable and reliable.

- Pay attention to abnormal noise: Pay attention to whether there is abnormal noise when the bearing is working, which may be a sign of bearing damage.

- Replacement intervals: Replace the bearings periodically, depending on service life and operating conditions, to ensure equipment reliability.

- Record maintenance: Record the maintenance of bearings, including lubrication time, replacement cycle, etc., to help improve the efficiency of equipment management.