Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Global Sourcing Expert Guide: Clutch Release Bearings Functions, Failures And Solutions

Introduction

The clutch release bearings are the key component connecting the input shaft of the automobile manual transmission and the clutch body, and plays a vital role in driving force transmission. When the driver depresses the clutch pedal, the clutch release bearing can disconnect the input shaft from the engine, thereby interrupting power transmission and realizing the “disengagement” function of the clutch. When the clutch pedal is released, the bearing can accurately transmit the engine’s driving force to the transmission input shaft, allowing the vehicle to regain power output.

Due to the harsh working conditions such as high-speed rotation and load impact, once the clutch release bearing fails, it will not only cause the gearbox to fail to operate normally, but may also cause serious damage to the entire drive system. Common fault types include bearing wear, jamming, abnormal noise, etc., which bring many hidden dangers and inconveniences to driving.

Therefore, the correct selection and continuous monitoring and maintenance of the clutch release bearing are particularly important. The world’s top automobile manufacturers and parts suppliers have been constantly exploring more advanced and reliable bearing solutions in order to extend the service life of bearings and reduce the risk of failure.

Structure And Characteristics Of Clutch Release Bearings

What are clutch release bearings?

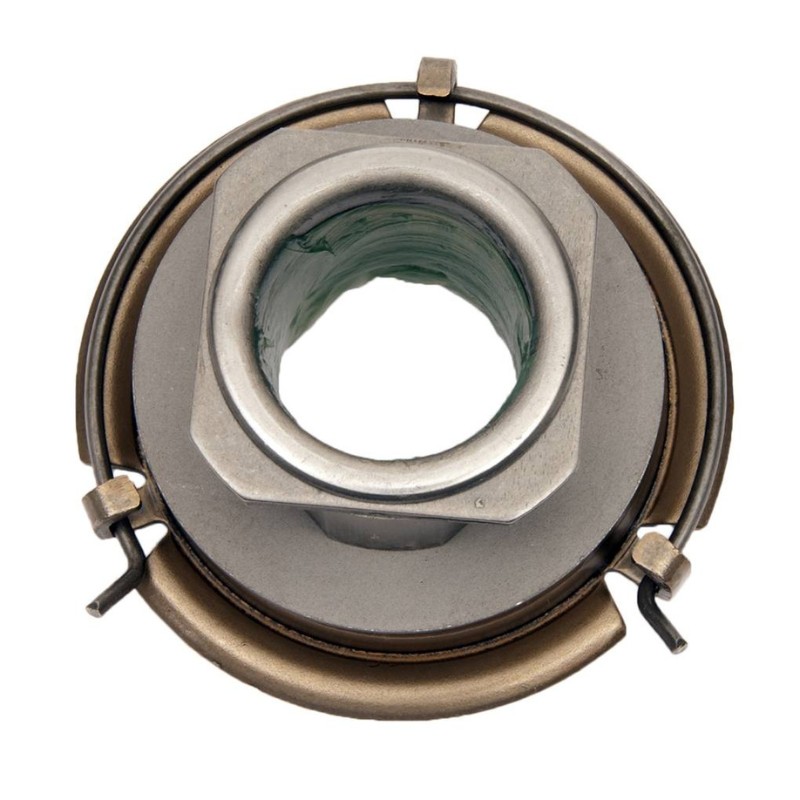

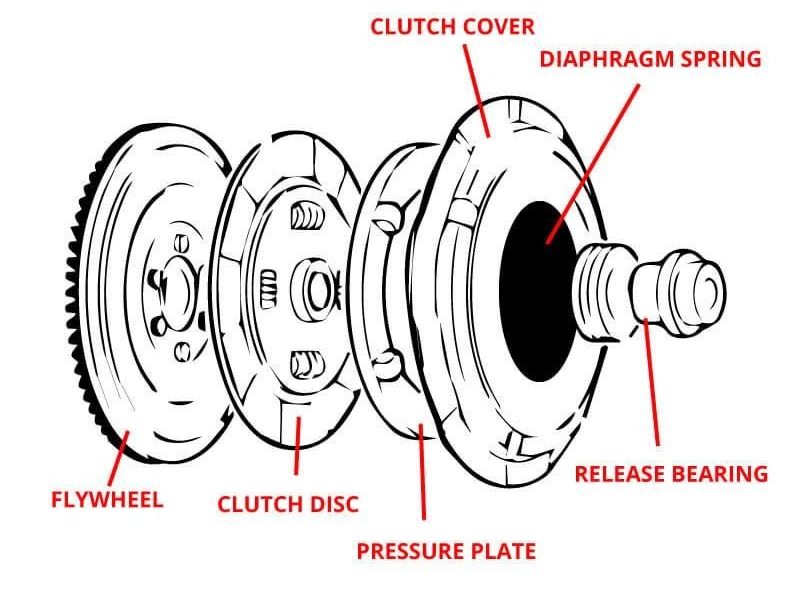

The clutch release bearing is a ball bearing and collar assembly. It reduces friction between the pressure plate lever and the release fork. A release bearing is a sealed unit package containing lubricant. It slides on a hub sleeve that protrudes from the front of the manual transmission or transaxle.

Clutch release bearings are stuck on the end of the clutch fork. Small spring clips secure the bearing to the fork. Movement of the shift fork in either direction then causes the release bearing to slide along the transmission hub sleeve.

Clutch release bearings structure

The clutch release bearing is usually located between the clutch’s pressure plate and flywheel and can be a ball bearing or a needle bearing. Its main components include:

Outer ring: Connected to the clutch release mechanism, it moves through the action of a rod or hydraulic device when the driver depresses the clutch pedal.

Inner ring: Connected to the pressure plate’s release fork and responsible for transmitting power from the engine to the gearbox.

Rolling elements (balls or needles): Located between the inner and outer rings, ensuring smooth rotation of the two rings during separation or engagement.

Cage: maintains the correct position and spacing of rolling elements to ensure stable operation.

Functional features

The high-quality bearing design reduces friction during operation, making clutch separation and engagement smoother and improving transmission efficiency.

Clutches generate a lot of heat during operation, and the release bearing must be able to withstand these conditions without failing.

And it can adapt to different driving conditions and environments, including frequent starts and stops, long driving hours and various weather and temperature conditions.

So the design must be strong enough to withstand a long service life, reducing replacement frequency and maintenance costs.

Types Of Clutch Release Bearings

Push-pull clutch release bearing

It is the most traditional type and is directly affected by the driver’s pedal force through a mechanical linkage, lever or cable system.

When the driver depresses the clutch pedal, the bearing is pushed mechanically, thereby realizing the separation and engagement of the clutch.

Hydraulic Release Bearing

The clutch is engaged and disengaged by a hydraulic system.

The hydraulic system consists of a hydraulic pump and a hydraulic cylinder that uses the pressure of the fluid to move the bearings to disengage or engage the clutch.

Self-adjusting clutch release bearing

It can automatically adjust the gap caused by the wear of the clutch friction plate to maintain the consistency and accuracy of the clutch operation.

This bearing design is more complex and contains built-in mechanisms to monitor and adjust the wear status of the friction plates.

The push-pull clutch release bearing has a simple structure, low cost, and is easy to maintain and replace. However, as technology advances, this type of bearing is used less and less in new models.

The hydraulic clutch release bearing provides a lighter operating feel and higher reliability, suitable for users who pursue a driving experience. However, maintenance costs are high once the hydraulic system leaks or fails.

Symptoms Of Clutch Release Bearing Failure And Causes Of Damage

The clutch release bearing is a vital link in the power transmission system. Its health directly affects the normal operation and driving experience of the vehicle.

Symptoms of failure often include unusual noise or vibration at the clutch pedal while driving, changes in pedal travel, clutch slippage, and a juddering sensation while driving. These problems often originate from bearing surface damage, poor lubrication, improper installation, overload operation, thermal failure, or internal debris contamination and fatigue wear.

Excessive radial or axial clearance between the inner and outer rings of the bearing, aging loss or contamination of the grease, excessive preload or insufficient installation accuracy, long-term load exceeding the design limit, and lubrication performance in high-temperature environments Falling, etc. will cause damage to the clutch release bearing, thus affecting the normal operation of the clutch. Timely recognition of these fault symptoms and analysis of their root causes is crucial to preventing larger vehicle failures and ensuring driving safety.

For a series of failures of the clutch release bearing, you should first check the lubrication status of the bearing and whether there is any debris intrusion, or the problem is caused by wear and improper installation of the bearing.

If the bearing is seriously damaged or has design defects, it is recommended to replace it in time.

When selecting a new clutch release bearing, vehicle model and usage needs should be considered, and original parts or high-quality replacements should be given priority to ensure optimal performance and extended service life.

Special or high-performance vehicles may require hydraulic or self-adjusting bearings.

When replacing, follow the installation guidelines to prevent the new bearing from failing quickly due to improper installation. Through these improvement measures, larger vehicle failures are avoided and the safe and reliable operation of the vehicle is ensured.

When And How Clutch Release Bearings Function

To achieve the dual functions of “separation” and “engagement”, the clutch release bearing needs to have reasonable axial displacement capability, and can accurately follow the clutch movement when the clutch pedal is moved, causing relative displacement of the inner and outer rings of the bearing to cut off or transmit power. ; And many key indicators need to be optimized, such as low noise vibration, low operating resistance, sufficient load-bearing capacity, good sealing performance and compact size, etc., to ensure smooth and reliable movement during the power switching process, efficient and lossless power transmission, and avoid power shock, Vibration noise and leakage pollution problems occur. It is this complex and precise “separation” and “engagement” actions that ensures that the entire clutch system and vehicle drive system can switch smoothly and continuously output power under any working conditions, making it possible for the car to start smoothly, shift gears, and achieve good driving. Performance is key.

Conclusion

As a global procurement expert, when faced with the selection and management of key components such as clutch release bearings, we must fully grasp and optimize multiple dimensions such as product quality, cost-effectiveness, and supply chain risks.

The clutch release bearing is a key “switch” in the power transmission system, and its performance determines the driving quality and reliability of the entire vehicle to a large extent. This requires the bearing to have sufficient axial displacement capacity, low noise and vibration levels, high load-bearing capacity, excellent sealing and compact structural design to adapt to the limited installation space to ensure stable operation under high-speed and high-load conditions.

Procurement strategies should be formulated with quality first, ensuring the performance of components by formulating strict technical specifications and quality standards. At the same time, a diversified supplier system is established to form a second- to third-tier supply structure to avoid the risks brought by a single supplier. In addition, establishing a quality traceability and feedback mechanism is crucial to quickly identify problems and take effective solutions. At the same time, establishing stable and long-term partnerships with suppliers can promote technical exchanges and mutual growth, further improving product quality and supply chain stability. Reasonable procurement plans and price negotiation strategies, based on cost accounting, are also the key to ensuring procurement efficiency and cost-effectiveness.

References

- 1.About the functional characteristics of “clutch release bearings“

- 2. Additional details about the “clutch release bearings”

- 3.Video about how the “clutch release bearings” works