Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Comprehensive Guide: What Brand Procurement Professionals Must Know About Thrust Ball Bearings Selection, Application and Maintenance

Introduction

Thrust Ball Bearings are bearings that use spherical balls as rolling elements. They comprise one or more spherical balls positioned within the bearing housing. Thrust ball bearings are typically used in low-speed applications and can handle small to medium axial loads.

What Are Thrust Ball Bearings

Thrust ball bearings are a type of bearing designed to withstand axial loads and are designed specifically to handle thrust or axial loads rather than radial loads.

Thrust ball bearings typically consist of three main parts: a ball bearing ring made up of steel balls, a stationary ring (called the seat ring), and a ring that rotates against the shaft (called the shaft ring). The steel balls are placed between the two rings to minimize friction and wear by means of a lubricant (e.g. oil or grease).

Types Of Thrust Ball Bearings And Applications

Thrust ball bearings can be categorized into two main types: unidirectional and bidirectional thrust ball bearings, depending on whether they are capable of handling axial loads in a single direction or in both directions. Unidirectional thrust ball bearings are designed to withstand loads in a single direction, while bidirectional thrust ball bearings are capable of handling loads in both directions.

Unidirectional Thrust Ball Bearings

Unidirectional thrust ball bearings consist of a collar, a seat ring, a ball collar and a set of balls and cages. Unidirectional thrust ball bearings cannot withstand radial loads.

Specific Applications

Automobile transmission system: in automobile clutches, one-way thrust ball bearings can withstand the thrust from the drive shaft and help the clutches work smoothly and efficiently.

Household appliances: in the rotating mechanism of washing machines, unidirectional thrust ball bearings help to withstand the axial loads generated by water and clothing, ensuring the efficient operation of the machine.

Pumps and compressors: Unidirectional thrust ball bearings are used in some pump and compressor designs to withstand the unidirectional thrust generated by fluid power.

Bidirectional Thrust Ball Bearings

Bidirectional thrust ball bearings consist of two seat rings, an intermediate shaft ring, two sets of balls and cages, and can withstand thrust in both directions. It is designed to withstand axial loads in both directions, but equally cannot withstand radial loads.

Specific Applications

Aircraft engines: Bidirectional thrust ball bearings are able to withstand the axial forces that vary during takeoff and landing in aircraft engines to ensure the stability of the engine.

Industrial machinery: in machinery that needs to withstand axial loads in both directions, such as certain types of gearboxes and steering systems, bidirectional thrust ball bearings provide the necessary support.

Machine tools: In the spindles of high-precision machine tools, bi-directional thrust ball bearings can withstand the bi-directional thrust caused by the cutting force and maintain the accuracy and stability of the spindle.

Key Differences Between Unidirectional And Bidirectional Thrust Ball Bearings

Unidirectional thrust ball bearings and bidirectional thrust ball bearings in the structure of the composition there are obvious differences. At the same time also led directly to the two in the performance of different.

Unidirectional thrust bearing structure is simple and compact, small volume, low manufacturing cost, but can only one-way bearing.

Bidirectional thrust bearings are more adaptable, more balanced bearing capacity, but the structure is complex, larger volume, higher manufacturing costs.

Because of their respective advantages, one-way thrust bearings are more suitable for only need to bear one-way axial load transmission system and support structure and other scenes, and two-way thrust bearings are more suitable for all kinds of rotating devices that require two-way support, such as wheel support, universal joint transmission.

Therefore, in the choice of thrust bearings, need to fully weigh the expected load direction, application scenarios, size limitations and costs and other factors, accurately grasp the differences between the two, so as to choose the most appropriate bearing solutions.

Differences Between Radial and Thrust ball Bearings

Radial bearings and thrust ball bearings are two very different types of bearings, in terms of structural design, force mode and application scenarios, there are some differences.

The design of radial bearings focuses on bearing radial loads, and the typical structure includes deep groove ball bearings, tapered roller bearings, etc. They usually consist of an inner ring, an outer ring, a rolling element and a cage. They are usually composed of inner ring, outer ring, rolling elements and cage, rolling elements in the inner and outer ring rolling on the raceway.

It is mainly subjected to radial load perpendicular to the direction of the axis, suitable for supporting rotating shafts or hubs and other scenes. They have excellent radial rigidity, but are less capable of carrying axial loads. They are widely used in various rotating machines to support rotating shafts, hubs and other components, such as motors, transmission systems, rollers and so on. Their role is to reduce rotational resistance, improve operational efficiency.

Thrust ball bearings are specially designed to withstand axial loads, typical structures include one-way thrust ball bearings and two-way thrust ball bearings. They consist of one or two beveled raceway ring, keep frame and rolling body (ball) composition, rolling body in the beveled raceway rolling.

They are mainly used for bearing axial loads in the axial direction, such as the weight load of wheels. They have excellent axial rigidity and load-carrying capacity, but have limited load-carrying capacity for radial loads. They are commonly used in, for example, bicycle wheel support systems and universal transmission devices. Their role is to withstand loads in the axial direction to ensure the stable operation of the device.

Therefore, when selecting bearings, it is necessary to accurately distinguish the expected main load direction (radial or axial), and select the appropriate radial bearings or thrust ball bearings according to the specific application scenarios.

Application Case Study

Background

Excavators play a vital role in fields such as construction, mining and civil engineering. These heavy machines require reliable components to support and withstand huge axial loads, and high load thrust ball bearings are one of the components that play a key role in such environments.

- Huge Axial Loads: In excavator operation, components such as the hydraulic arm and bucket bar are subjected to huge axial loads, generated during soil excavation and material handling.

- Constantly Changing Working Conditions: Excavators face constantly changing working conditions in actual operation, including various soil types, different depths of excavation, and loads in different directions.

- Axial Load Capacity: These bearings are specifically designed to withstand large axial loads, ensuring that critical components such as the hydraulic arm and bucket bar can operate stably under a variety of operating conditions.

- Highly Accurate Motion Control: The ball design of the highly loaded thrust ball bearings provides excellent motion control, enabling the excavator to perform a variety of digging tasks accurately and consistently.

- Durability and Reliability: The durability and reliability of high loaded thrust ball bearings ensure long operation of excavators in harsh working environments such as dusty conditions and high humidity variations.

For Thrust Ball Bearings Effective Results Achieved

Increased productivity: The high load carrying capacity of the bearings allows the excavator to complete digging tasks faster and more efficiently, increasing productivity.

Reduced Maintenance Costs: Durability and reliability reduce the risk of mechanical failure and minimize maintenance downtime, thus reducing maintenance costs.

Enhanced Operational Precision: High-precision motion control ensures that the excavator performs accurate maneuvers under a wide range of operating conditions, improving operational precision.

How Thrust Ball Bearings Work

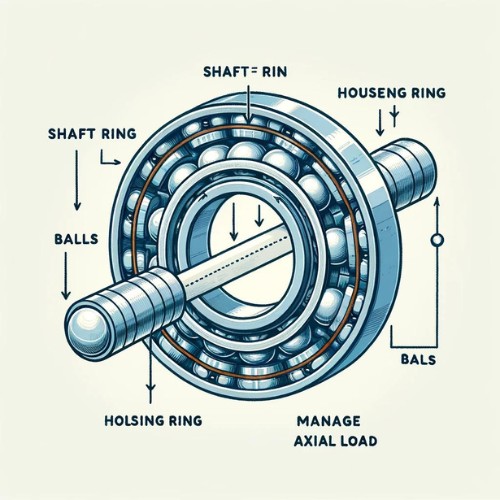

As shown in the figure, we can learn more about the structure of thrust ball bearings and how they work to manage axial loads.

When an axial load (i.e. a force parallel to the axis) acts on the shaft, this force is transferred to the ball through the collar.

After the balls receive the axial load, the rolling action between them distributes the load evenly to the seat ring. This dispersion mechanism allows the bearings to withstand large axial loads while maintaining low friction.

The seat ring receives the load from the ball and transfers it to the bearing seat or the structure of the machine, thereby completing the load management process.

The diagram also plots the direction of axial load, illustrating how the thrust ball bearing manages the load. This design effectively reduces friction as the balls roll between the shaft ring and seat ring, allowing the bearing to withstand high loads while maintaining efficient operation.

Causes Of Thrust Ball Bearings Failure And How To Avoid Them

Key failure factors of thrust ball bearings include improper installation, overloading, insufficient lubrication, contamination, as well as wear and fatigue. In order to extend the service life of bearings and prevent possible failures, appropriate measures should be taken:

- Proper installation: Use proper tools and techniques to ensure proper bearing alignment and installation.

- Observe load specifications: Ensure operating conditions do not exceed the bearing’s design load.

- Regular Lubrication: Lubricate bearings regularly to reduce friction and wear.

- Prevent contamination: Use seals to protect bearings from dust, dirt and moisture. Extra caution should be used when operating in dusty or wet environments.

- Regular inspection and maintenance: Regularly check the status of the bearings, including changes in wear, temperature and noise, so that problems can be discovered and solved in time.

Conclusion

In the procurement strategy, one should have a deep understanding of the various types of thrust ball bearings and their application characteristics. This is not only the choice of Unidirectional and Bidirectional thrust ball bearings, but also involves how to make a reasonable trade-off between quality and cost. Suppliers who provide high-quality products and excellent after-sales service should be selected. In addition, by establishing a continuous monitoring and evaluation system to detect and solve problems in a timely manner, the risk of large-scale failures can be greatly reduced. Therefore, adopting a reasonable procurement strategy to ensure the efficient performance and reliability of thrust ball bearings is crucial to improving overall operating efficiency and equipment stability.

References

1.Detailed analysis of how “Thrust bearings” work

2.Detailed overview of ”Thrust ball bearings “from TAMESON.

3.About “Thrust bearings” reduce friction and support axial loads

I like it when folks come together and share thoughts.

Great site, stick with it!

My brother suggested I might like this website. He was totally right.

This post truly made my day. You cann’t imagine simply how much time I had spent

for this information! Thanks!