Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Comprehensive Analysis: What Are The Ball Bearings Used For

Introduction

Ball bearings are quintessential components in the vast world of mechanical engineering, serving pivotal roles in reducing friction between moving parts. Comprising an array of balls encased between two concentric rings, ball bearings facilitate the transfer of radial and axial loads through their seamless rolling mechanism. Ball bearings are available in a variety of designs and material compositions for use in a wide range of industries.This comprehensive analysis delves into the various types, designs, materials, and innovative applications of ball bearings, illuminating their importance to modern technology and industry.

Understanding Ball Bearings

Ball bearings are essential mechanical components used to enable the smooth and efficient motion of low friction between two rotating shafts and their stationary parts. These bearings are made of an inner ring, an outer ring, two rows of balls, and a cage to keep the ball separated, this type allows for high-speed operation and load-supporting capacity.

Ball bearings Main Functions

Reduced Friction – Ball bearings are specifically designed to reduce friction between moving parts within machinery. By providing a smooth ball that rolls rather than slides, resistance to movement is reduced and the reduction in friction also increases the efficiency of the machine.

Supporting Loads – Ball bearings are designed to support radial and axial (thrust) loads. The ability to effectively handle these loads makes ball bearings very useful in a variety of environments.

Enhancing Precision and Alignment– In machinery, ball bearings help maintain the alignment of connected components. They ensure that components move along their paths without deviation.

Increased speed – By reducing friction, ball bearings allow machinery to operate at higher speeds.

Improved service life and reliability – Reducing friction and evenly distributing loads on bearing surfaces reduces the risk of premature wear.

Principle Of Operation

Ball bearings operate by rolling motion to minimize friction and allow for smooth rotary movement of mechanical components. They are made of the number of small spherical balls, which sits in a two concentric rings; an inner and an outer ring. When subjected to radial or axial loads, these balls evenly displace the force on their surfaces, reducing strain and wear on the bearing. When the inner ring rotates with the shaft or component it is coupled to, these balls roll along grooves in the outer ring which does not move in most cases. It also creates far less contact area than a sliding motion, reducing mechanical wear and energy loss due to friction as well. Typically the balls are contained by a cage between rotating parts to avoid them colliding against one another during operation, most generating no rotation. This setup allows the ball bearings to manage both high-speed rotation and diverse loads, making them essential in many applications.

Benefits Of Ball Bearings

- Reduce friction for smoother operation and lower energy consumption.

- Evenly distribute loads, reduce stress, and increase durability.

- Low friction properties enable machines to run faster, which improves efficiency and performance.

- Ensure consistent motion and alignment for greater precision.

- Reduce wear and extend bearing life.

- Easy to replace, requiring less frequent maintenance.

- Compact design, small size, and high efficiency.

- Versatility, and adaptability to a wide range of environments and applications.

Ball Bearings Design

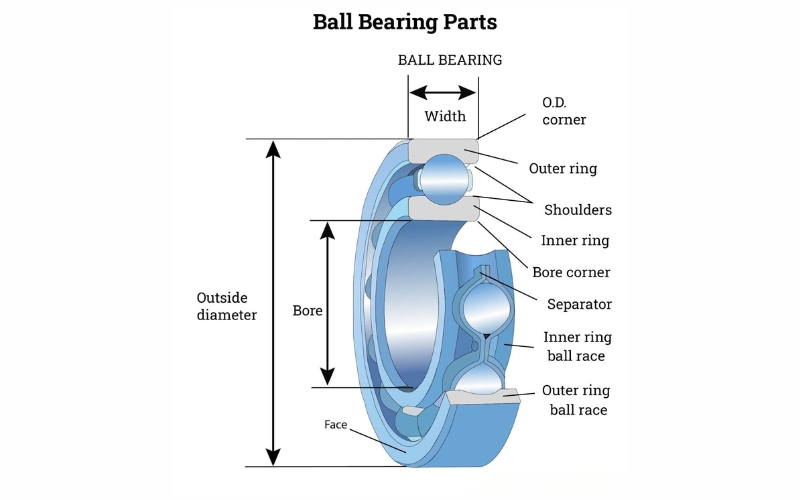

Ball bearings: consist of an inner ring, an outer ring, balls, and a cage (ball retainer).

The inner ring is a pressure fit to the shaft on which it must rotate. The outer ring, which fits into a housing generally remains stationary. The balls, or rolling elements that act to reduce the friction and allow for smooth movement between the rings, are described as residing betwixt these two rings. The balls are held in position by a cage, which also prevents the balls from colliding with each other. This configuration permits a hood load managing spread and decreased get-in-touch with tension.

Types Of Ball Bearings

There are many types of ball bearings, and different designs can meet different needs. The following is a detailed analysis of various types. The common types are as follows:

- Deep groove ball bearings are characterized by the large radial load capacity and the ability to also support axial loads in both directions. Designed for durability and easy maintenance.

- These bearings are able to support higher axial loads carrying capacity in one direction along with radial loads. The Permissible angular misalignment between the inner and outer rings is limited to 1.5 and 2 degrees, depending on the series.

- Thrust ball bearings are made to handle axial loads but cannot tolerate radial loads.

- These bearings are particularly useful in applications where misalignment might occur between the housing and the shaft.

- Utilizing ceramic balls with steel inner and outer rings, these bearings offer superior durability and resistance to wear and tear. Ceramic materials are lighter, harder, and more durable than steel, and also less prone to thermal expansion.

- These bearings feature a flange on the outer ring, which facilitates easier mounting and positioning within a housing.

- Made from stainless steel, these bearings are naturally resistant to corrosion and oxidation.

- These small-sized bearings are used in applications where space is very limited and precision is key. Despite their small size, they are engineered to maintain high performance and are capable of handling both radial and axial loads.

Materials Used In Balls In Ball Bearings

The materials used for the balls in these bearings are selected based on the specific requirements of the application, including load capacity, speed, environmental conditions, and durability. Here’s a closer look at the characteristics and applications of different materials used for balls in ball bearings:

● Steel

Steel is the most commonly used material for ball bearings due to its excellent hardness and wear resistance, which ensure long service life and reliability. Steel balls can withstand high loads and are suitable for applications involving high speeds and temperatures.

● Stainless Steel

Stainless steel balls offer enhanced corrosion resistance compared to regular steel, making them suitable for use in environments exposed to moisture or corrosive substances. Stainless steel retains much of the load-bearing capacity of standard steel but usually at a higher cost.

● Ceramic

Ball bearings in particular utilize ceramic materials such as Silicon Nitride (Si3N4) or Aluminum Oxide (Al2O3) for their superior toughness and ability to be used in vacuum forming applications due to them being very hard, light, and thermally resistant. Ceramic balls are lighter and harder than steel, which reduces centrifugal forces, wear, and heat generation at high speeds.

● Glass

Glass balls are significantly less common and are primarily used where lighter loads are involved and non-metallic properties are required. They are non-magnetic and provide good corrosion resistance, though they are more fragile compared to metal and ceramic balls.

● Plastic

Plastic balls are used in applications requiring lightweight, non-conductive, and highly corrosion-resistant bearings. Materials like polyoxymethylene (POM), nylon, and polytetrafluoroethylene (PTFE) are common.

When selecting a ball material for bearings, several factors must be considered:

- Load Capacity: Metallic balls (steel, stainless steel) are preferred for high-load applications.

- Environmental Resistance: Stainless steel, ceramic, and plastic are chosen based on the chemical and moisture exposure of the bearing.

- Speed Requirements: Ceramic balls are advantageous in high-speed applications due to their low density and high hardness.

- Cost-Effectiveness: Steel is generally the most cost-effective option, with specialized materials like ceramics being more expensive but offering unique properties for challenging environments.

Applications Of Ball Bearings

The following is a detailed analysis of ball bearing applications in different industries:

➊. Automobile:

- Wheels: Bearings reduce friction between the moving parts of a vehicle’s wheels and axles, ensuring smooth operation and reduced wear.

- Transmissions: Bearings in transmissions ensure that gears mesh properly and run smoothly, effectively transferring power from the engine to the wheels.

- Engine: Bearings are used in various engine components to reduce friction between moving parts.

➋. Aerospace:

- Aircraft Controls: Bearings are used in the control mechanisms of aircraft to facilitate precise movements and to withstand changes in temperature and pressure.

- Landing Gear: Bearings in the landing gear must be highly durable and capable of handling extreme loads and stresses during landing operations.

- Engine Components: Aerospace bearings are specially designed to withstand high temperatures and stresses, ensuring reliability and safety in aircraft engines.

➌. Industrial Machinery:

- Conveyors: Bearings allow for the smooth operation of conveyor belts, which are essential for the mass movement of goods in facilities like factories, airports, and distribution centers.

- Fans: Bearings in industrial fans must be capable of operating at high speeds and often in high-temperature conditions.

- Pumps: Bearings support the rotating shafts in pumps, ensuring efficient movement of fluids in various industrial processes.

➍. Consumer Electronics:

- Hard Drives: Bearings allow for the quiet and smooth operation of the spinning disks in traditional hard drives.

- DVD Players: Bearings are used in the spinning mechanisms of DVD players to ensure that discs rotate smoothly for proper reading and writing of data.

➎. Medical Equipment:

- MRI Machines: High-precision bearings are essential for the smooth operation of the rotating parts within MRI machines and are crucial for generating accurate images.

- Robotic Surgery Tools: Bearings in robotic surgery systems allow for precise and controlled movement, which is vital for performing delicate surgical operations.

➏. Marine Applications:

- Ship Components: Bearings are used in various ship components, including propeller shafts and deck machinery, where they must be durable and resistant to harsh marine conditions.

➐. Renewable Energy:

- Wind Turbines: Bearings are used in the nacelle and rotor of wind turbines, where they must withstand variable and high-load conditions to ensure efficient energy production.

Conclusion

Why Are Ball Bearings So ImportantBall bearings are used in a variety of industries because they increase the efficiency and service life of machines by reducing friction. Critical to the functioning of advanced complex systems — ranging from automotive to aerospace to renewable energy — these components appear practically everywhere in the modern world. In the future, we should see more developments from ball bearing technology to more advanced materials to produce stronger, more resilient products and incorporate smart technology within the ball bearing allowing operators to better predict when the machine may breakdown. These will surely increase their applications and effectiveness and keep industrial machinery and systems and systems management standards on their toes.

References

- 1.FAQs about different types of” ball bearings” from GGBearings Company

- 2. Something About“ Ball Bearing ”Uses in Everyday Life from Mrosupply Company

- 3. Detailed in-depth analysis of “ball bearings” from Iqsdirectory Company