Categories

Bearings for Retarder Applications: Enhancing Performance and Reliability

Table of Contents

Introduction

In the rapidly evolving landscape of automotive technology, precision is a non-negotiable aspect, and within this intricate machinery, the often-underappreciated hero is the bearing in retarder systems. This blog post serves as an exhaustive guide for manufacturers and procurement officers in the automotive industry, delving deep into the crucial role of precision bearings in ensuring the efficiency and reliability of retarder systems. Throughout this exploration, FHD Bearings takes the center stage, showcasing its commitment to providing top-notch solutions tailored for retarder applications.

Understanding Retarder Systems

Overview of Retarder Technology

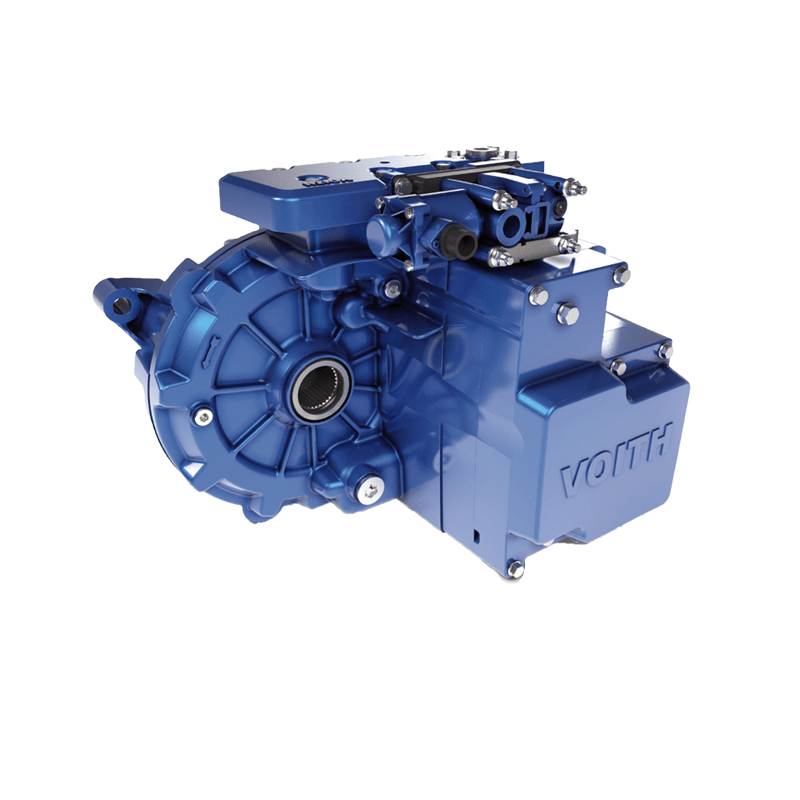

Retarders, integral to controlled vehicle deceleration, manifest in hydraulic, electric, and exhaust variants. Each type serves unique functions, fundamentally shaping the landscape of modern automotive braking systems. Understanding these distinctions is essential for selecting the right bearings to optimize the performance of these systems.

Types of Retarders and Their Functions

Hydraulic Retarders

- Hydraulic systems leverage fluid dynamics for reliable and controlled braking. A profound grasp of the principles governing hydraulic retarders is imperative for choosing bearings that align with their operational requirements.

Electric Retarders

- Operating on the principle of converting kinetic energy into electricity for efficient braking, electric retarders demand specialized bearings. These bearings must accommodate the specific dynamics of energy conversion and dissipation.

Exhaust Retarders

- The unique function of harnessing exhaust gases to create resistance for controlled deceleration sets exhaust retarders apart. Bearings for such systems must withstand the distinct challenges posed by this mode of operation.

The Crucial Role of Bearings in Retarders

Importance of Precision Bearings for Retarder

Beyond the conventional understanding of bearings as mere support components, precision bearings play a pivotal role in determining the overall efficiency and reliability of retarder systems. FHD Bearings specializes in the production of precision bearings tailored to meet the specific demands of retarder applications.

Impact on Overall System Efficiency

Efficiency in retarder systems is intricately linked to the quality of the bearings employed. FHD Bearings distinguishes itself by engineering bearings that contribute significantly to the overall efficiency of retarder applications. These bearings are crafted to withstand the rigors of deceleration, ensuring longevity and reliability.

Key Considerations for Selecting Bearings for Retarder Applications

The selection of bearings for retarder applications involves nuanced considerations, including load capacity, endurance, temperature resistance, and compatibility with different retarder systems. FHD Bearings excels in meeting these multifaceted requirements, providing a diverse range of products optimized for hydraulic, electric, and exhaust retarder systems.

Exploring Bearing Requirements

Load Capacity and Endurance

Load Capacity

- Bearings for retarder applications must withstand varying loads during deceleration. FHD Bearings offers solutions designed to handle these dynamic load conditions with ease.

Endurance

- Endurance is a critical factor in the durability of bearings in challenging conditions and high temperatures. FHD Bearings engineers its products to exhibit exceptional endurance, ensuring reliability under diverse operational scenarios.

Temperature and Environmental Challenges

Temperature Resistance

- Bearings in retarder applications often encounter high temperatures. FHD Bearings addresses this challenge by designing bearings with enhanced temperature resistance, ensuring consistent performance even in extreme conditions.

Environmental Compatibility

- Environmental conditions vary, and bearings must be compatible with diverse settings. FHD Bearings provides solutions that can withstand a range of environmental conditions, enhancing the adaptability of their products.

Compatibility with Retarder Systems

Different retarder systems demand specific bearing characteristics. FHD Bearings offers a comprehensive range of products optimized for hydraulic, electric, and exhaust retarder systems. This ensures that clients can choose bearings tailored to the unique requirements of their specific applications.

Types of Bearings for Retarder Applications

In the context of retarder applications, the choice of bearings becomes pivotal in achieving optimal performance and longevity. Here, we explore some commonly used types of bearings in retarder systems, emphasizing their characteristics and suitability for specific applications.

Ball bearings emerge as the most widely used bearings in reducers, known for their versatility and efficiency. The spherical design of both inner and outer rings allows them to withstand radial and axial loads, making them ideal for applications with higher speeds and larger loads. Common models include the 6200, 6300, and 6400 series, among others.

Tapered roller bearings are designed to handle both radial and axial loads, providing flexibility in preload adjustments. With conical surfaces on both inner and outer rings, they allow for a wide range of angle adjustments in bearing preload. These bearings are particularly suitable for applications with lower speeds and larger loads, and common models include the 30200, 30300, and 31300 series.

Cylindrical Roller Bearings

Cylindrical roller bearings excel in bearing large radial loads, albeit with limitations in bearing axial loads and featuring small radial gaps. Recognized for their large radial load capacity, they are suitable for applications with lower speeds and larger loads. Common models encompass the NU, NJ, NUP, and N series.

Thriving in scenarios where axial load is the primary concern, thrust ball bearings offer specific advantages. These bearings are mainly designed to bear axial loads, with the inner ring being spherical and the outer ring either convex or concave. Thrust ball bearings find their niche in occasions with low speed and large load, with common models including the 51100, 51200, and 51300 series.

Reference Suggestions for Bearing Selection

When selecting bearings for retarder applications, reference points play a crucial role in making informed decisions. Considerations such as operational speed, load characteristics, application specifics, temperature considerations, and compatibility with the overall system design are paramount. FHD Bearings, with its expertise, ensures that clients have the necessary guidance to make optimal choices.

FHD Bearings: A Reliable Partner

Introduction to FHD Bearings

FHD Bearings, headquartered in China, emerges as a beacon of quality and reliability in the bearing manufacturing industry. With a reputation built on precision engineering and a commitment to excellence, FHD Bearings stands as a reliable partner for those seeking top-tier solutions for retarder applications.

Specialization in Bearings for Automotive Applications

With a dedicated focus on the automotive sector, FHD Bearings has honed its expertise in producing bearings that meet the stringent requirements of retarder applications. The company’s specialization ensures that clients receive products specifically tailored to the unique demands of the automotive industry.

OEM/ODM Services Catering to Retarder Manufacturers

FHD Bearings goes beyond conventional offerings, providing original equipment manufacturer (OEM) and original design manufacturer (ODM) services. This enables manufacturers to access custom solutions that align seamlessly with their specific retarder applications. The ability to customize bearings ensures a precise fit for diverse systems.

Product Range for Retarder Applications

Overview of FHD's Bearing Catalog

Extensive Catalog

- FHD Bearings boasts a comprehensive catalog of bearings designed for various automotive applications. The extensive range caters to different needs within the automotive industry, offering clients a wide selection of high-quality bearings.

Diverse Solutions

- Recognizing the diverse requirements of retarder systems, FHD Bearings provides a spectrum of solutions. This diversity ensures that clients can find bearings that perfectly match the specifications and operational needs of their specific retarder systems.

Bearings Optimized for Different Retarder Types

Hydraulic Retarder Bearings

- FHD Bearings offers bearings tailored to meet the specific requirements of hydraulic retarder systems. These bearings are engineered to excel in the unique conditions associated with hydraulic braking, ensuring optimal performance.

Electric Retarder Bearings

- Precision-engineered bearings for electric retarder applications are a hallmark of FHD’s product offerings. These bearings are designed to facilitate efficient energy conversion, contributing to the overall effectiveness of electric retarder systems.

Exhaust Retarder Bearings

- Bearings designed specifically for exhaust retarder systems showcase FHD’s commitment to providing solutions for varied applications. These bearings are equipped to withstand the challenges posed by exhaust retarder operations.

Customization Options for Tailored Solutions

Tailoring Bearings to Specific Needs

- FHD Bearings excels in collaborative customization, allowing clients to address unique requirements. The ability to tailor bearings to specific needs ensures a precise fit, enhancing the overall performance of retarder systems.

Flexibility in Design

- Recognizing the intricate designs associated with retarder applications, FHD Bearings offers flexibility in design modifications. This allows clients to fine-tune bearings to match their exact specifications, fostering a seamless integration into their systems.

Quality Assurance and Certifications

FHD's Commitment to Quality

Quality Control Processes

- At FHD Bearings, stringent quality control processes are implemented at every stage of production. This commitment to quality ensures that each bearing that leaves the production line meets the highest standards.

Materials and Manufacturing Standards

- Adhering to international standards for materials and manufacturing processes, FHD Bearings guarantees the use of high-quality materials. This commitment underpins the reliability and longevity of their bearings.

Industry-Standard Certifications

ISO Certification

- FHD Bearings holds ISO certification, attesting to its commitment to quality management systems. This certification serves as a testament to the company’s dedication to meeting and exceeding international quality standards.

Other Industry Certifications

- In addition to ISO certification, FHD Bearings complies with other industry-specific certifications. These certifications further validate the quality and reliability of their products, instilling confidence in clients.

Meeting the Demands of Discerning Customers like Vladimir

Understanding Customer Needs

- FHD Bearings excels in understanding the unique needs of customers like Vladimir, who seek a balance between quality and competitive pricing. This understanding forms the foundation for delivering solutions that align with the specific requirements of clients.

Balancing Quality and Cost-effectiveness

- A key strength of FHD Bearings lies in its ability to provide competitive pricing without compromising on quality. This approach resonates with customers like Vladimir, who prioritize both quality and cost-effectiveness in their procurement decisions.

Long-term Value Proposition

- FHD’s focus on creating long-term value aligns seamlessly with Vladimir’s profit model. By delivering consistent quality and reliability, FHD Bearings becomes a strategic partner in enhancing the overall value proposition for clients over the long term.

Overcoming Procurement Challenges

Efficient Communication Channels

Dedicated Account Management

- FHD Bearings addresses the challenge of inefficient communication by assigning dedicated account managers. These managers streamline communication, ensuring clarity and efficiency in interactions with clients.

Clear and Transparent Communication

- Open channels of communication are integral to FHD Bearings’ approach. Clear and transparent communication minimizes misunderstandings, fostering a collaborative and productive relationship with clients.

Streamlined Ordering Process

User-friendly Online Ordering System

- Recognizing the need for efficiency in the procurement process, FHD Bearings provides a user-friendly online ordering system. This intuitive platform simplifies the ordering process, catering to the preferences and convenience of clients like Vladimir.

Customized Ordering Solutions

- Acknowledging the diversity of client needs, FHD Bearings offers customized ordering solutions. This flexibility ensures that clients can tailor their orders to specific requirements, enhancing the overall procurement experience.

Addressing Certificate Fraud Concerns

Transparent Certification Process

- FHD Bearings addresses concerns related to certificate fraud by maintaining a transparent certification process. This transparency builds trust with clients, providing assurance regarding the authenticity and validity of certifications.

Educational Resources

- To further mitigate concerns related to certification processes, FHD Bearings provides clients with educational resources. These resources empower clients with knowledge, enabling them to make informed decisions and navigate the certification landscape with confidence.

Case Studies: FHD Bearings in Retarder Applications

Success Stories with Global Automotive Partners

Collaborative Success

- FHD Bearings showcases instances of collaborative success with global automotive partners. These success stories highlight the effectiveness of FHD’s bearings in real-world applications, contributing to the overall success of automotive systems.

Performance Enhancements

- Demonstrating the positive impact of FHD’s bearings on the performance and reliability of retarder systems, these case studies provide tangible evidence of the value that FHD Bearings brings to its partnerships.

Real-world Performance Enhancements

Improved Efficiency

- Case studies presented by FHD Bearings highlight how their bearings contribute to the overall efficiency of retarder applications. Improved efficiency translates to enhanced performance, a critical factor for automotive manufacturers.

Extended Lifespan

- Examples of bearings surpassing industry standards emphasize the extended lifespan of retarder systems equipped with FHD Bearings. This extended lifespan not only ensures reliability but also contributes to cost savings over the operational life of the systems.

Positive Impact on Profit Margins

Cost-Efficiency Case Studies

- FHD Bearings illustrates the positive impact of its cost-effective solutions on the profit margins of clients like Vladimir. These case studies showcase how FHD’s offerings contribute to the financial success of its clients, aligning with their business objectives.

Long-term Partnerships

- Highlighting the longevity of partnerships between FHD Bearings and clients, these examples underscore the sustained profitability that FHD brings to the table. Long-term relationships are a testament to the enduring value that FHD Bearings provides to its clients.

Technical Expertise at Your Service

FHD's Technical Support Team

Access to Technical Experts Clients benefit from direct access to FHD’s technical support team, ensuring guidance on bearing selection.

Collaborative Problem-Solving Approach FHD’s collaborative approach assists clients like Vladimir in solving technical challenges associated with retarder applications.

Guidance on Bearing Selection for Optimal Retarder Performance

Tailored Recommendations FHD’s technical experts provide personalized recommendations, ensuring optimal performance in retarder applications.

Continuous Support Ongoing support and guidance throughout the entire product lifecycle, from selection to maintenance.

Global Reach and Logistics Excellence

FHD's Presence in Key Export Countries

Global Distribution Network FHD Bearings strategically positions itself in key export countries, ensuring accessibility to clients worldwide.

Localized Support Local offices and support teams facilitate seamless communication and logistics.

Seamless Logistics for Timely Deliveries

FHD’s robust supply chain management ensures on-time deliveries, crucial for clients operating in a competitive market.

Flexible Logistics Solutions Adaptable logistics solutions cater to the unique needs of clients, ensuring a hassle-free procurement process.

Simplifying Procurement for International Clients

International Procurement Made Easy FHD Bearings simplifies the procurement process for international clients, offering a smooth and reliable experience.

Customs Compliance Expertise in customs regulations ensures a streamlined process for clients like Vladimir, minimizing delays.

Competitive Pricing without Compromising Quality

FHD's Pricing Strategy

Competitive Pricing Model FHD Bearings adopts a competitive pricing model, offering affordability without compromising on quality.

Transparent Pricing Structure Transparent pricing structures empower clients to make informed decisions, aligning with Vladimir’s focus on competitive pricing.

Balancing Quality and Cost-effectiveness

Value for Money FHD Bearings provides clients with a clear value proposition, balancing quality with cost-effectiveness.

Long-term Cost Savings Investments in FHD’s bearings translate into long-term cost savings, contributing to the financial success of clients.

Long-term Value Proposition for Clients like Vladimir

Strategic Partnerships FHD Bearings focuses on building strategic, long-term partnerships with clients like Vladimir, ensuring mutual success.

Adapting to Market Changes FHD’s agile approach to market dynamics ensures sustained value and relevance in a competitive industry.

Industry Trends and Innovations

Emerging Technologies in Retarder Systems

Innovation in Retarder Technology Stay updated on the latest advancements in retarder systems and how FHD Bearings aligns with these innovations.

Adaptive Bearing Solutions FHD continuously adapts its bearing solutions to complement emerging technologies in retarder systems.

FHD's Adaptive Strategies for Future Industry Shifts

Market Forecasting FHD Bearings anticipates industry shifts and proactively adjusts its strategies to remain at the forefront of technological advancements.

Investment in Research and Development A commitment to R&D ensures FHD’s bearings remain innovative and relevant in an evolving market.

Staying Ahead in the Automotive Bearing Market

Industry Leadership FHD Bearings positions itself as an industry leader, consistently staying ahead in the competitive automotive bearing market.

Continuous Improvement FHD’s dedication to continuous improvement ensures clients receive cutting-edge solutions for their retarder applications.

Collaborative R&D Initiatives

Partnering for Technological Advancements

Open Collaboration FHD Bearings actively seeks collaborations with industry partners to drive technological advancements in bearing solutions.

Shared Knowledge Collaborative R&D initiatives involve the sharing of knowledge and resources to push the boundaries of bearing technology.

FHD's Contribution to Industry Innovations

Innovation Showcases Discover specific instances where FHD Bearings has contributed to innovations in bearing technology.

Technical Contributions FHD’s technical expertise plays a pivotal role in advancing industry standards for bearings in retarder applications.

Building a Sustainable Future Together

Sustainability in Bearing Production Explore FHD Bearings’ commitment to sustainable manufacturing practices, contributing to a greener future.

Environmental Responsibility FHD Bearings aligns its practices with global sustainability goals, fostering a responsible and eco-friendly manufacturing approach.

Beyond Bearings: FHD's Comprehensive Support

Additional Services for Automotive Manufacturers

Comprehensive Solutions FHD Bearings goes beyond being a bearing supplier, offering a suite of services to support the overall needs of automotive manufacturers.

Tailored Solutions Beyond Bearings Customized services cater to the unique requirements of clients, providing holistic support beyond the supply of bearings.

The FHD Advantage in a Competitive Market

Competitive Edge Understand how FHD Bearings provides clients with a competitive advantage in a crowded automotive bearing market.

Client Success Stories Real-world examples of clients who have experienced success by choosing FHD Bearings as their preferred partner.

Strengthening Client Relationships through Value-added Services

Building Lasting Partnerships FHD Bearings prioritizes building lasting partnerships with clients, ensuring mutual growth and success.

Continuous Improvement Feedback Loop A feedback loop encourages clients to provide insights, fostering continuous improvement in FHD’s services.

Conclusion

In summary, this comprehensive exploration of bearings for retarder applications highlights the crucial role that FHD Bearings plays in enhancing the performance and reliability of automotive systems. From understanding retarder technology to providing customized solutions and supporting clients through a range of services, FHD Bearings stands as a reliable partner for manufacturers and procurement officers seeking excellence in the automotive bearing market.

For inquiries and to explore the FHD difference in retarder applications, please contact us at sales@fhdbearings.com.