Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Swivel Bearings: Key Considerations for Procurement and Selection

Introduction

Importance of Swivel Bearings in Industrial Applications

Swivel bearings play a pivotal role in various industrial applications, facilitating smooth and controlled movement in machinery and equipment. These bearings allow for rotational movement around a central axis, enabling precise positioning and maneuverability. In manufacturing, swivel bearings are essential for conveyor systems, robotic arms, and assembly lines, enhancing efficiency and productivity. Additionally, in automotive and aerospace industries, swivel bearings contribute to the functionality of steering mechanisms and aircraft landing gear, ensuring safety and stability. Overall, the versatility and reliability of swivel bearings make them indispensable components in diverse industrial settings, where precision and agility are paramount.

Purpose of the Guide

The purpose of this guide is to provide professionals involved in procuring swivel bearings with comprehensive and practical guidance. By offering a structured approach to selecting swivel bearings, this guide aims to empower decision-makers to make informed choices that align with their project requirements and performance expectations. Through detailed exploration of considerations such as vendor selection, material specifications, and performance criteria, readers will gain valuable insights to navigate the complexities of sourcing swivel bearings effectively. Ultimately, this guide seeks to enhance the procurement process, enabling professionals to optimize the performance and reliability of their industrial applications.

Understanding Swivel Bearings

Understanding Swivel Bearings begins with grasping their definition and functionality. Swivel bearings, also known as swivel joints or pivot bearings, are mechanical components designed to enable rotational movement around a fixed axis. They facilitate smooth and controlled rotation, allowing machinery and equipment to change direction or orientation with ease. Swivel bearings are crucial in applications where precise positioning and maneuverability are essential, such as conveyor systems, robotic arms, and vehicle steering mechanisms.

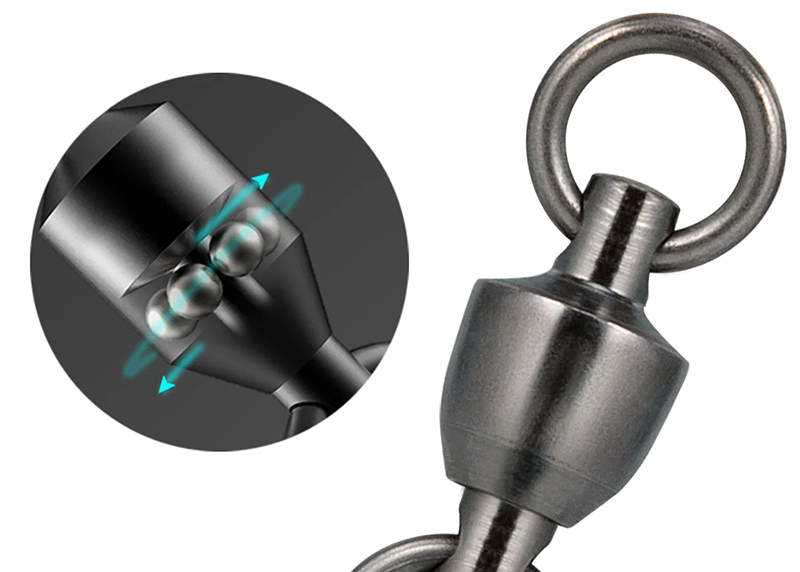

Delving deeper, it’s essential to recognize the various types of swivel bearings available in the market. These include ball swivel bearings, roller swivel bearings, tilt swivel bearings, and combination swivel bearings. Ball swivel bearings utilize ball bearings to support rotational movement, offering low friction and high load-bearing capacity. Roller swivel bearings employ cylindrical rollers to distribute load and reduce friction, ideal for heavy-duty applications. Tilt swivel bearings allow for tilting movement in addition to rotation, providing flexibility in positioning. Combination swivel bearings combine different bearing mechanisms to achieve specific performance requirements. Understanding the distinctions among these types is fundamental for selecting the most suitable swivel bearings for a particular application.

Identifying Application Requirements

Load Capacity and Weight Distribution

Identifying application requirements, specifically load capacity and weight distribution, is paramount in selecting the right swivel bearings. Load capacity refers to the maximum weight a bearing can support without compromising performance or safety. It’s crucial to accurately assess the expected loads and distribute them evenly across the bearings to prevent premature wear or failure. Factors such as dynamic loads, static loads, shock loads, and directional changes must be considered to determine the appropriate load capacity. Additionally, understanding the weight distribution within the system ensures that each bearing receives an optimal load, maximizing efficiency and longevity. By meticulously evaluating load requirements, professionals can ensure the chosen swivel bearings meet the demands of their specific application, minimizing downtime and maintenance costs.

Operating Environment

Identifying application requirements extends to assessing the operating environment in which the swivel bearings will function. The operating environment encompasses factors such as temperature, corrosion resistance, and exposure to contaminants. Temperature variations can affect the performance and lifespan of swivel bearings, making it essential to select materials capable of withstanding extreme temperatures or fluctuations. Corrosion resistance is crucial, especially in environments with high moisture or chemical exposure, to prevent degradation and ensure long-term reliability. Moreover, considering the presence of contaminants like dust, dirt, or abrasive particles is essential for selecting bearings with appropriate seals or shields to maintain smooth operation and prevent premature wear. By meticulously evaluating the operating environment, professionals can mitigate risks and select swivel bearings that offer optimal performance and durability in their specific application context.

Material Considerations

Common Materials Used in Swivel Bearings

Material considerations are pivotal in selecting swivel bearings that can withstand the demands of their intended applications. Several common materials are used in the construction of swivel bearings, each offering unique properties and benefits. Steel, known for its strength and durability, is a popular choice for heavy-duty applications where robustness is essential. Stainless steel, prized for its corrosion resistance, is ideal for environments prone to moisture or chemical exposure. Nylon bearings offer low friction and excellent wear resistance, making them suitable for applications requiring smooth, quiet operation. Bronze bearings excel in high-load situations and offer good corrosion resistance. Understanding the properties of these materials is critical for selecting swivel bearings that can endure the specific operating conditions of the application.

Material Selection Factors

When considering materials for swivel bearings, several factors come into play to ensure optimal performance and longevity. Strength and durability are paramount considerations, especially in applications subjected to heavy loads or harsh operating conditions. The chosen material must withstand the forces exerted upon it without succumbing to deformation or failure. Compatibility with the operating environment is crucial, as exposure to extremes of temperature, moisture, or chemicals can degrade certain materials over time. Cost considerations also play a role, balancing performance requirements with budget constraints. Additionally, factors such as lubrication requirements and ease of maintenance should be evaluated to ensure the chosen material aligns with the overall operational needs of the system. By carefully weighing these material selection factors, professionals can choose swivel bearings that offer the optimal balance of performance, durability, and cost-effectiveness for their specific application.

Performance Criteria

Swivel Range and Flexibility

Performance criteria such as swivel range and flexibility are crucial considerations when selecting swivel bearings for industrial applications. Swivel range refers to the maximum angle through which the bearing can rotate, determining the extent of motion allowed within the system. A wider swivel range provides greater flexibility in positioning and maneuverability, accommodating varying operational requirements. Additionally, flexibility pertains to the smoothness and ease of movement offered by the bearing, ensuring that motion transitions are seamless and precise. Factors such as bearing design, lubrication, and load distribution influence the swivel range and flexibility of the bearing. By prioritizing these performance criteria, professionals can choose swivel bearings that offer the necessary range of motion and maneuverability to meet the specific demands of their application, enhancing operational efficiency and performance.

Noise and Vibration Levels

Performance criteria such as noise and vibration levels are critical considerations when selecting swivel bearings for industrial applications. Excessive noise and vibration can lead to operational inefficiencies, increased wear and tear, and even safety hazards. Swivel bearings should be designed to minimize noise generation and vibration transmission, ensuring smooth and quiet operation. Factors such as bearing design, material selection, and lubrication play significant roles in controlling noise and vibration levels. Bearings with precision machining and high-quality components tend to exhibit reduced noise and vibration characteristics. Additionally, proper installation and maintenance practices can further mitigate noise and vibration issues. By prioritizing these performance criteria, professionals can select swivel bearings that contribute to a quieter and smoother operating environment, enhancing productivity and reducing maintenance requirements.

Maintenance Requirements

Maintenance requirements are essential performance criteria to consider when selecting swivel bearings for industrial applications. Swivel bearings that require minimal maintenance contribute to lower downtime, reduced operational costs, and extended lifespan. Factors such as lubrication intervals, inspection frequency, and ease of access for maintenance tasks influence the overall maintenance requirements of swivel bearings. Bearings designed with self-lubricating features or sealed designs can reduce the need for frequent lubrication and minimize maintenance efforts. Additionally, bearings constructed with durable materials and robust seals tend to exhibit greater resistance to contaminants and wear, reducing the frequency of maintenance interventions. By prioritizing swivel bearings with low maintenance requirements, professionals can enhance operational efficiency and reliability while optimizing the overall lifecycle cost of their equipment.

Life Expectancy and Reliability

Performance criteria such as life expectancy and reliability are crucial factors to consider when selecting swivel bearings for industrial applications. The life expectancy of swivel bearings refers to the anticipated duration of reliable operation before requiring replacement or significant maintenance. Bearings with longer life expectancy contribute to reduced downtime, lower maintenance costs, and enhanced overall productivity. Reliability, on the other hand, pertains to the consistency and predictability of bearing performance under varying operating conditions. Factors such as material quality, design robustness, and manufacturing precision influence the reliability of swivel bearings. Bearings designed and manufactured to stringent quality standards and specifications typically exhibit higher reliability and prolonged service life. By prioritizing swivel bearings with favorable life expectancy and reliability characteristics, professionals can ensure the long-term performance and dependability of their industrial equipment and machinery.

Compatibility with Existing Systems

Compatibility with existing systems is a crucial aspect to consider when selecting swivel bearings for industrial applications. Interface and mounting considerations involve ensuring that the dimensions, mounting configurations, and attachment methods of the chosen swivel bearings align with those of the existing equipment or machinery. Compatibility in this regard streamlines installation processes and reduces the need for modifications or customizations, saving time and resources.

Additionally, integration with other components is essential for seamless operation within the larger system. Swivel bearings must interface smoothly with adjacent components, such as shafts, housings, and structural supports, to maintain stability and functionality. Compatibility in integration ensures that the swivel bearings complement the overall system design and do not introduce bottlenecks or points of failure.

Moreover, retrofitting options enable the replacement or upgrade of existing bearings without extensive modifications to the surrounding infrastructure. Swivel bearings with retrofitting capabilities offer flexibility and versatility, allowing for easy upgrades or replacements to enhance system performance or accommodate changing requirements. By prioritizing compatibility with existing systems, professionals can ensure smooth integration, minimize downtime, and optimize the performance of their industrial equipment.

Vendor Selection

Vendor selection is crucial in procuring swivel bearings for industrial applications, requiring careful consideration of key factors. Research and evaluation are essential to identify potential vendors offering swivel bearings meeting project requirements. Thorough market research and gathering information on product offerings, capabilities, and customer reviews are vital. Additionally, evaluating vendors based on reputation and track record is essential for assessing reliability and trustworthiness. A vendor with a proven track record of delivering high-quality swivel bearings on time and within budget inspires confidence.

Quality assurance and certification are critical considerations in vendor selection. Ensuring vendors adhere to rigorous quality standards and possess relevant certifications demonstrates commitment to product quality and reliability. Certifications like ISO 9001 indicate adherence to recognized quality management systems, providing assurance of consistent performance. Pricing and cost transparency are significant. Transparent pricing policies and clear communication on pricing factors and terms help mitigate the risk of unexpected costs and align with budgetary constraints.

In conclusion, a comprehensive approach to vendor selection, including research, reputation, quality assurance, and pricing transparency, is essential for procuring swivel bearings that meet requirements reliably and cost-effectively. Prioritizing these factors enables professionals to mitigate risks and enhance the success of industrial projects.

Conclusion

In conclusion, swivel bearings are indispensable components in various industrial applications, enabling precise movement and enhancing efficiency. This guide provides comprehensive insights into selecting swivel bearings, covering key considerations such as load capacity, operating environment, materials, performance criteria, compatibility, and vendor selection. By understanding these factors and making informed choices, professionals can optimize the performance, reliability, and longevity of their industrial systems. Prioritizing thorough assessment and selecting reputable vendors ensures successful procurement, ultimately contributing to safer, more efficient, and cost-effective operations in diverse industrial settings.

References

- 1.”Swivel Bearings” from McMaster-Carr;

- 2. “SWIVEL, Ball bearing swivel” from Petzl;

- 3. “Selecting a Swivel” from Trenchless Technology Magazine.

Hey Theгe. I foᥙnd your blog using msn. This is a very well

written article. I will be sure to bⲟokmark it and come back to read more of үour usefuⅼ

info. Thanks for the post. I’ll ԁefinitely comeback.

Thank you for your feedback. We remain committed to our ongoing efforts to provide high-quality content.

Thank you for the kind words! I’m glad you found the article helpful. Looking forward to your return!