Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Understanding Wheel Bearings: Anatomy, Function, and Importance

Introduction

Definition and Basic Function

Wheel bearings are crucial components in a vehicle’s wheel assembly, serving as the interface between the wheel hub and the axle shaft. Their primary function is to facilitate smooth and frictionless rotation of the wheel, enabling efficient vehicle movement. These bearings consist of several key elements, including outer and inner rings, bearings, a cage or retainer, and seals or shields. By reducing friction between moving parts and supporting both axial and radial loads, wheel bearings play a vital role in ensuring the stability, control, and safety of the vehicle during operation.

Historical Evolution

The evolution of wheel bearings traces back thousands of years, initially crafted from primitive materials like wood and leather to support the weight of early carts and chariots. Over time, advancements in metallurgy led to the development of more durable bearings made from materials like bronze and iron. The industrial revolution marked a significant turning point, with the introduction of precision machining techniques and the mass production of standardized bearings. In the modern era, advancements in materials science and engineering have further refined wheel bearing design, enhancing durability, efficiency, and performance to meet the demands of contemporary automotive applications.

Anatomy of Wheel Bearings

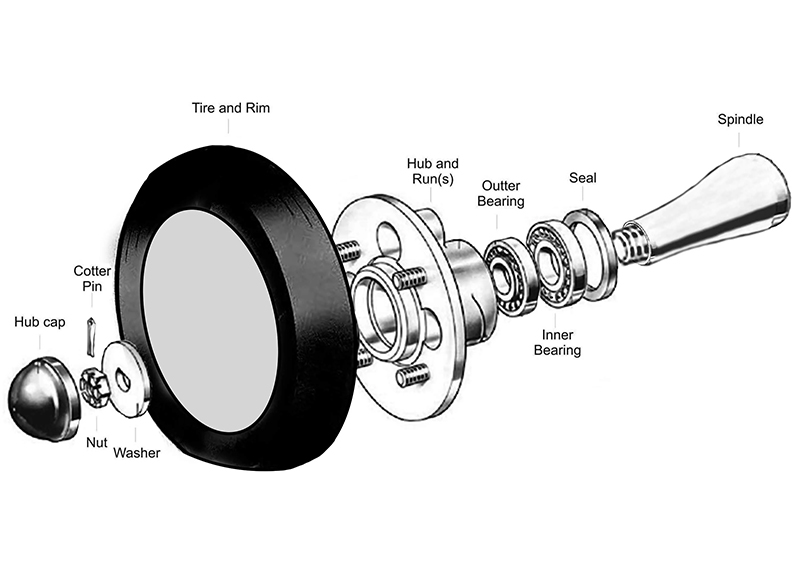

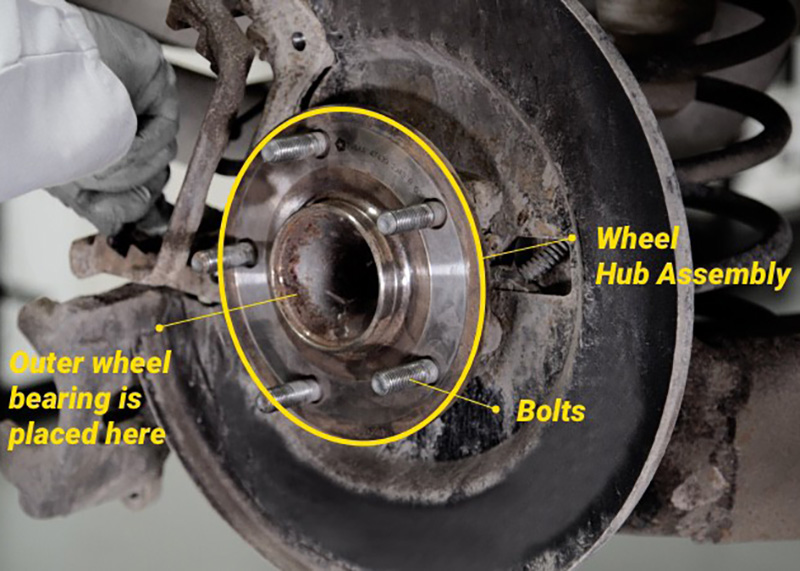

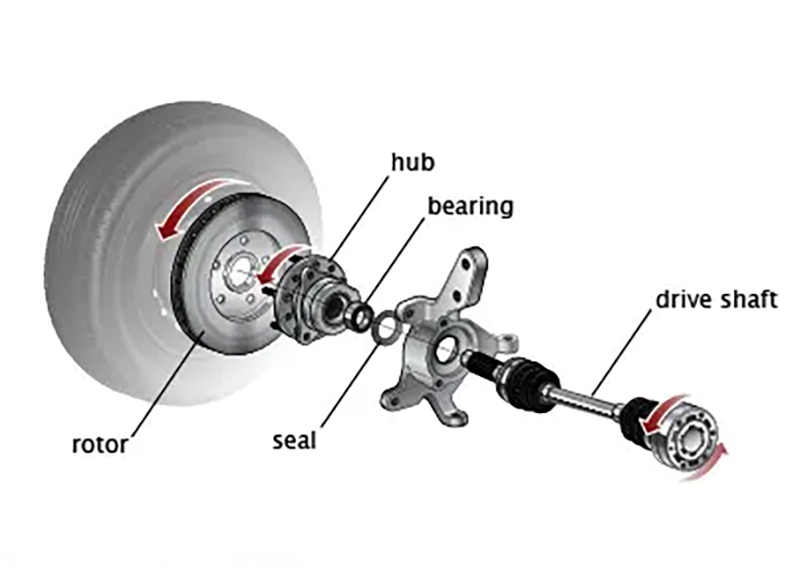

The anatomy of wheel bearings encompasses several critical components that work together to facilitate smooth and efficient rotation of the vehicle’s wheels. At its core are the outer and inner rings, which encase the bearings and provide structural support. These rings are precision-engineered to withstand the forces encountered during vehicle operation.

The bearings themselves are small, often spherical or cylindrical, and are positioned between the inner and outer rings to reduce friction and enable free movement. Surrounding the bearings is a cage or retainer, which maintains their proper alignment and spacing within the assembly. Additionally, seals or shields help protect the bearings from contaminants such as dirt, water, and debris, extending their lifespan and ensuring optimal performance.

Together, these components form a cohesive unit that plays a crucial role in supporting the vehicle’s weight, managing axial and radial loads, and maintaining stability and control during driving maneuvers. Understanding the intricate anatomy of wheel bearings is essential for proper maintenance, inspection, and replacement to ensure the longevity and safety of the vehicle.

Types of Wheel Bearings

- Tapered roller bearings are designed to handle both radial and axial loads by utilizing tapered rollers that guide the inner and outer rings along the bearing axis.

- They are commonly used in heavy-duty vehicles and applications where high load-carrying capacity and durability are essential, such as trucks and large trailers.

- Ball bearings utilize spherical balls to minimize friction between the inner and outer rings, allowing for smooth rotation with minimal resistance.

- They are suitable for light to moderate loads and are commonly found in passenger vehicles, bicycles, and industrial machinery.

- Double row bearings feature two rows of rolling elements (balls or rollers) within a single bearing assembly.

- This design increases load-carrying capacity and provides greater stiffness, making them ideal for applications with higher loads and dynamic forces.

Generation 3 Bearings:

- Generation 3 bearings are advanced hub bearing units that integrate wheel bearings, hub assemblies, and ABS sensors into a single, pre-assembled unit.

- They offer improved performance, reliability, and ease of installation compared to traditional bearing systems, making them increasingly popular in modern vehicles.

Function of Wheel Bearings

Load Support and Friction Reduction

The function of wheel bearings encompasses various critical roles essential for vehicle operation. Firstly, they provide vital load support, bearing the weight of the vehicle and its occupants while enduring the forces encountered during acceleration, braking, and cornering maneuvers. This load support function is crucial for maintaining the structural integrity of the wheel assembly and ensuring stable and safe driving conditions. Additionally, wheel bearings contribute significantly to friction reduction within the wheel assembly, allowing for smooth rotation with minimal resistance. By minimizing friction between the rotating components, wheel bearings help improve fuel efficiency, reduce wear and tear on suspension components, and enhance overall vehicle performance. Together, these functions underscore the importance of wheel bearings in promoting both safety and efficiency on the road.

Axial and Radial Load Management

Another critical function of wheel bearings is the management of axial and radial loads encountered during vehicle operation. Axial loads are those exerted parallel to the axis of rotation, such as those experienced during cornering or sudden changes in direction. Radial loads, on the other hand, act perpendicular to the axis of rotation, like those encountered during acceleration or braking. Wheel bearings are designed to effectively distribute and support both types of loads, ensuring that the vehicle remains stable and responsive under varying driving conditions. By managing axial and radial loads efficiently, wheel bearings contribute to the overall safety, performance, and longevity of the vehicle’s suspension system and wheel assembly.

Wheel Rotation and Speed Control

Wheel bearings play a crucial role in facilitating smooth and controlled wheel rotation, contributing to the vehicle’s overall speed control and stability. As the wheel rotates, the bearings minimize friction between the rotating components, allowing for effortless movement and precise speed regulation. This smooth rotation is essential for maintaining consistent vehicle speed, especially during acceleration and deceleration. Additionally, wheel bearings help ensure uniform wheel movement, preventing wobbling or uneven rotation that could compromise driving stability. By enabling precise wheel rotation and speed control, wheel bearings enhance the vehicle’s handling characteristics, responsiveness, and overall driving experience, ultimately contributing to safer and more enjoyable journeys on the road.

Importance of Wheel Bearings in Vehicle Suspension Systems

Link between Chassis and Wheels

Wheel bearings serve as a crucial link between the chassis and the wheels within a vehicle’s suspension system, ensuring seamless interaction and transmission of forces. They provide the necessary support for the wheels to rotate smoothly while bearing the weight of the vehicle and its occupants. This direct connection between the chassis and the wheels allows for efficient transfer of forces generated during driving maneuvers, such as acceleration, braking, and cornering. By maintaining stability and alignment between the chassis and the wheels, wheel bearings play a fundamental role in optimizing suspension performance, enhancing ride quality, and promoting overall vehicle safety and control on various road surfaces and driving conditions.

Impact on Ride Quality

The importance of wheel bearings in vehicle suspension systems extends to their significant impact on ride quality. These bearings are integral components that directly influence the smoothness and comfort of the ride by facilitating the rotation of the wheels with minimal friction and resistance. When wheel bearings are functioning optimally, they contribute to a vibration-free and quiet driving experience, absorbing road imperfections and irregularities to provide passengers with a comfortable journey. However, worn or damaged wheel bearings can lead to increased noise, vibration, and harshness (NVH) levels, resulting in a noticeable deterioration in ride quality. Therefore, maintaining properly functioning wheel bearings is essential for ensuring a pleasant and enjoyable driving experience for vehicle occupants.

Influence on Steering Stability

The importance of wheel bearings in vehicle suspension systems extends to their significant influence on steering stability. Wheel bearings play a crucial role in maintaining the alignment and proper functioning of the wheels, directly impacting the vehicle’s steering response and stability. When wheel bearings are in good condition, they contribute to smooth and precise steering control, allowing drivers to maintain their desired trajectory with confidence. However, worn or faulty wheel bearings can lead to irregularities in wheel movement, causing steering play, wandering, or even loss of control. Therefore, ensuring the integrity and functionality of wheel bearings is essential for promoting safe and predictable steering behavior, enhancing overall driving confidence, and reducing the risk of accidents on the road.

Signs of Wheel Bearing Failure

Signs of wheel bearing failure manifest through various indicators that signal potential issues within the wheel assembly. One common symptom is the presence of unusual noises, such as grinding, whirring, or rumbling sounds, particularly when the vehicle is in motion. These noises typically originate from the affected wheel or axle area and may increase in intensity as vehicle speed increases. Additionally, vibration or a wobbling sensation may be felt through the steering wheel or vehicle chassis, especially at higher speeds, indicating possible bearing wear or damage. Uneven tire wear is another telltale sign of wheel bearing problems, as faulty bearings can cause excessive or irregular tire tread wear patterns. Moreover, the activation of the ABS (anti-lock braking system) warning light on the dashboard may indicate issues with wheel speed sensors, which are often integrated with wheel bearing assemblies in modern vehicles. Recognizing these signs of wheel bearing failure is crucial for timely diagnosis and replacement to prevent further damage and ensure safe and smooth vehicle operation.

Causes of Wheel Bearing Damage

Wheel bearing damage can stem from various factors that compromise their structural integrity and functionality. One common cause is a lack of proper lubrication, which leads to increased friction and wear between the bearing components. Without sufficient lubrication, the rolling elements within the bearing can become overheated and worn, ultimately leading to premature failure. Contamination from dirt, water, and other debris is another significant contributor to wheel bearing damage. These contaminants can infiltrate the bearing assembly, causing abrasion, corrosion, and accelerated wear of the bearing surfaces. Overloading the vehicle beyond its designated weight capacity can also exert excessive stress on the wheel bearings, causing them to wear out more quickly. Additionally, prolonged exposure to high temperatures, such as those generated during heavy braking or driving in hot climates, can degrade the lubricant and accelerate bearing wear. Recognizing and addressing these common causes of wheel bearing damage through proper maintenance and care are essential for preserving the longevity and performance of the vehicle’s wheel bearings.

Wheel Bearing Maintenance

Wheel bearing maintenance is essential for ensuring the longevity and optimal performance of the vehicle’s wheel bearings. Regular inspection and lubrication are key components of effective maintenance practices. Periodic inspections should be conducted to check for signs of wear, damage, or contamination, such as unusual noises, vibration, or uneven tire wear. Additionally, wheel bearings should be properly lubricated according to the manufacturer’s recommendations to reduce friction and minimize wear between the bearing components. Lubrication intervals may vary depending on driving conditions and mileage, so it’s essential to follow the maintenance schedule outlined in the vehicle’s owner’s manual. Furthermore, timely replacement of worn or damaged wheel bearings is critical to prevent further damage to the vehicle’s suspension system and ensure safe and reliable operation. By prioritizing regular maintenance and inspection of wheel bearings, drivers can promote vehicle safety, performance, and longevity.

Choosing the Right Wheel Bearings

Choosing the right wheel bearings is paramount to ensuring optimal performance, safety, and durability for your vehicle. Factors such as compatibility with the vehicle model and specifications should be carefully considered to ensure proper fitment and functionality. It’s essential to select wheel bearings that meet the load-carrying requirements and performance expectations of your vehicle, particularly if it is used for towing or heavy-duty applications. Quality and durability are also crucial considerations, as high-quality bearings made from reputable manufacturers are more likely to withstand the rigors of daily driving and provide long-lasting reliability. Additionally, evaluating the cost-effectiveness of different bearing options can help strike a balance between quality and affordability. Whether opting for original equipment manufacturer (OEM) bearings or aftermarket replacements, conducting thorough research and consulting with automotive professionals can help drivers make informed decisions when choosing the right wheel bearings for their vehicles.

Conclusion

In conclusion, wheel bearings are indispensable components of a vehicle’s wheel assembly, supporting its weight, managing loads, and enabling smooth rotation. From their historical evolution to their modern-day functions and maintenance, understanding the importance of wheel bearings is vital for ensuring vehicle safety, performance, and longevity. Recognizing signs of failure and addressing common causes of damage through regular maintenance are essential practices. Choosing the right wheel bearings, considering factors like compatibility, quality, and durability, is crucial for optimal performance. By prioritizing proper care and selection, drivers can ensure smooth and safe journeys on the road, enhancing both the efficiency and enjoyment of their driving experience.

References

- 1.”Why Wheel Bearings Are Important, And What Happens When They Fail” from Car Throttle;

- 2. “Wheel Bearings and Hubs 101: What You Need to Know” from Mevotech;

- 3. “Everything You Need To Know About Wheel Bearings” from The Drive.