In-Depth Comparison: Wheel vs Hub Bearings

Table of Contents

Introduction

In the intricate tapestry of automotive engineering, bearings stand as the silent sentinels of motion, ensuring the seamless operation of vehicles across diverse terrains and conditions. Within this landscape, wheel bearings and hub bearings emerge as stalwart guardians, each bearing its own mantle of responsibility in the pursuit of vehicular excellence. Let us embark on a comprehensive journey, delving deeper into the realms of these indispensable components to unravel their complexities and unveil their significance in the realm of automotive performance and safety.

Unveiling the Essence of Wheel Bearings

Deciphering Wheel Bearings

Wheel bearings are unassuming yet vital components that enable your wheels to rotate smoothly with minimal friction. These bearings are found within the wheel hub assembly and facilitate the rotation of the wheel around the axle.

Anatomy and Mechanisms of Wheel Bearings

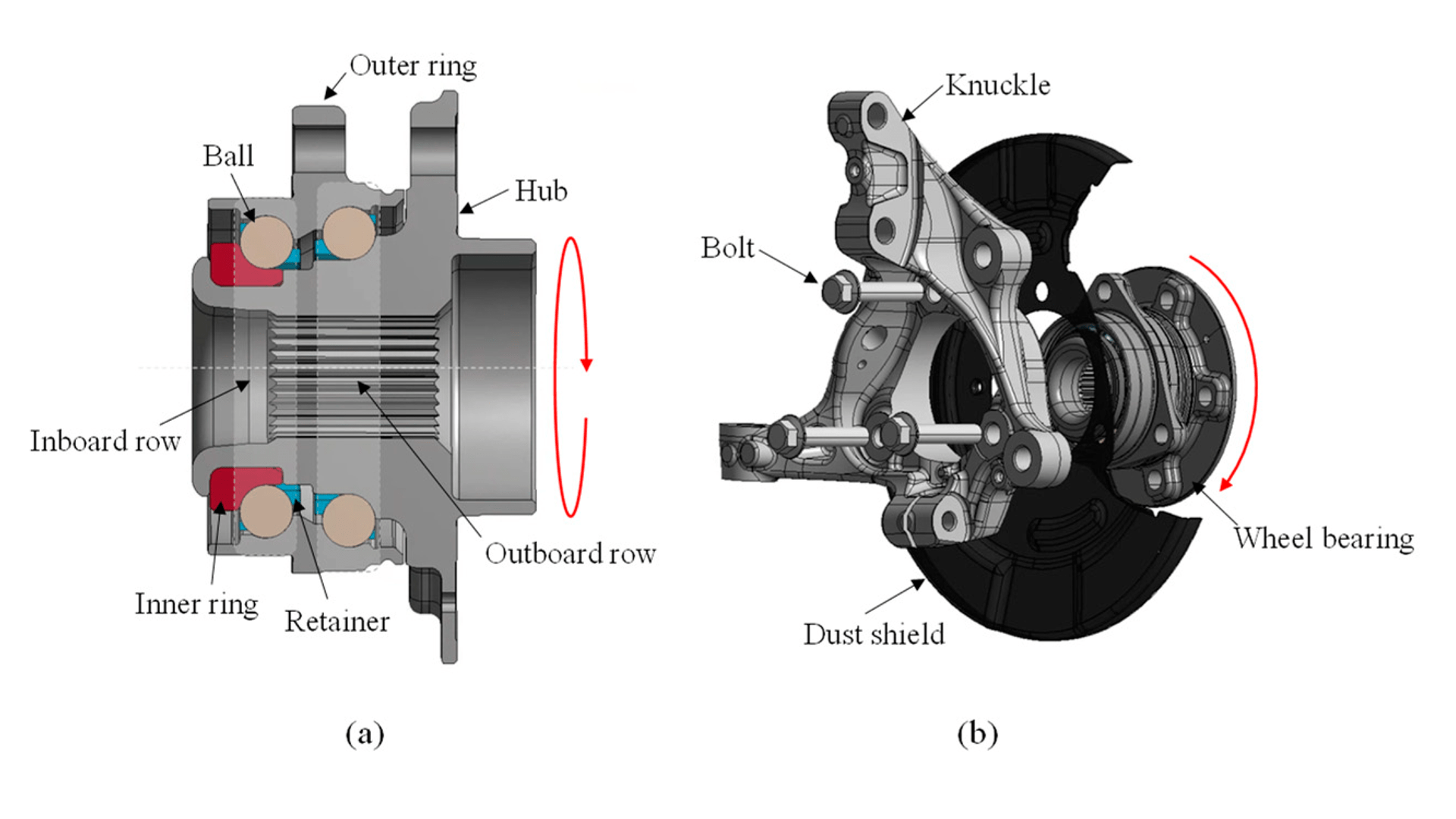

The anatomy of wheel bearings is a testament to precision engineering, comprising intricately machined inner and outer races, steel balls arranged with meticulous spacing, and a cage to maintain their alignment. Encased within protective seals or shields, these bearings operate in a realm of minimal friction, shielded from the ravages of contaminants that seek to impede their performance.

Operational Dynamics of Wheel Bearings

Functioning as the fulcrum upon which vehicular motion pivots, wheel bearings shoulder the weight of the vehicle while facilitating the rotational movement of the wheels with unparalleled efficiency. Enduring the rigors of immense pressure and temperature fluctuations, these bearings epitomize durability and reliability, underscoring their indispensable role in the automotive ecosystem.

Variants of Wheel Bearings

The evolutionary journey of automotive engineering has given rise to two primary variants of wheel bearings: tapered roller bearings and ball bearings. While the former finds its niche in the annals of automotive history, gracing the axles of older vehicles with its robust presence, the latter has emerged as the preferred choice in modern automotive design, embodying the virtues of efficiency and versatility.

Delving into the Realm of Hub Bearings

What Are Hub Bearings?

Hub bearings, often referred to as hub assemblies, are integral components of a vehicle’s suspension system. They comprise the wheel hub and bearing, pre-assembled as a single unit.

Anatomy and Functionalities of Hub Bearings

Designed to withstand the crucible of vehicular dynamics, hub bearings bear the brunt of the vehicle’s weight while facilitating smooth wheel rotation and seamless integration with the steering system. Encapsulated within hermetically sealed units, these bearings operate in a realm of perpetual motion, demanding minimal maintenance and offering maximum reliability.

Diverse Strains of Hub Bearings

The evolution of hub bearing design has led to the emergence of various iterations, each meticulously tailored to cater to the diverse needs and exigencies of modern automotive applications. From first-generation pioneers to third-generation innovators, these bearings embody the relentless pursuit of excellence in engineering and design.

Deciphering the Dichotomy: Wheel Bearings vs. Hub Bearings

Navigating the Terrain of Location and Installation

In the intricate dance of automotive assembly, the placement and installation of bearings play a pivotal role in determining the efficiency and efficacy of the vehicle. While wheel bearings find their abode within the confines of the wheel hub, intricately intertwined with the spindle, hub bearings grace the automotive landscape as pre-assembled entities, simplifying the installation process and streamlining maintenance efforts.

Primary Functions Unveiled

While both wheel bearings and hub bearings play instrumental roles in facilitating vehicular motion, their mandates and operational parameters differ significantly. While wheel bearings primarily shoulder the responsibility of supporting wheel rotation, hub bearings transcend this mandate, integrating seamlessly with the steering system to ensure precision and responsiveness in driving dynamics.

Maintenance Mandates: Contrasts and Comparisons

The realm of bearing maintenance is a dichotomous landscape, characterized by contrasting mandates and methodologies. While wheel bearings demand meticulous upkeep, including periodic lubrication and replacement rituals, hub bearings bask in the glory of maintenance-free existence, beckoning replacements only as complete units, thus streamlining maintenance efforts and minimizing downtime.

Signs of Wear: Harbingers of Impending Issues

The symphony of vehicular operation is often accompanied by subtle cues and telltale signs, heralding the onset of bearing anomalies and impending issues. Failing wheel bearings may announce their demise through grinding or squeaking symphonies, serenading the vehicle’s journey with discordant notes, while hub bearing anomalies manifest as loose steering and irregular tire wear, signaling a call to action and prompting proactive intervention.

Embracing Proactive Measures: Replacement and Maintenance Protocols

Preserving Vehicular Integrity: Wheel Bearing Replacements

In the relentless pursuit of vehicular excellence, timely intervention is paramount in addressing the harbingers of failing wheel bearings, safeguarding against catastrophic consequences and exorbitant repair bills. By embracing a regimen of proactive maintenance and informed decision-making, vehicle owners can ensure a journey devoid of tumultuous twists and turns, thus fostering a culture of safety and reliability on the roads.

Navigating the Threshold of Hub Bearing Replacements

Embracing the ethos of prompt action, addressing hub bearing anomalies ensures steering precision and vehicular safety, heralding a journey devoid of turbulence and uncertainty. By heeding the subtle cues and signs of bearing wear, vehicle owners can avert potential crises and navigate the terrain of vehicular maintenance with confidence and poise, thus fostering a culture of preparedness and foresight.

Sourcing Bearings: A Confluence of Prudence and Precision

The selection of bearings is a pivotal decision, fraught with implications for vehicular performance and safety. By meticulously considering factors such as vehicle make and model, bearing type, and the imprimatur of quality and brand, vehicle owners can ensure optimal performance and longevity, thus charting a course toward vehicular excellence and reliability.

Embarking on the Journey of DIY Bearing Replacements

DIY Wheel Bearing Replacements: An Odyssey of Empowerment

For the aficionados of automotive craftsmanship, the realm of DIY wheel bearing replacements beckons, promising a voyage of self-sufficiency and empowerment. By equipping themselves with the requisite tools and knowledge, DIY enthusiasts can embark on a journey of discovery, gaining insights and honing their skills while ensuring the integrity and performance of their vehicles.

Demystifying the DIY Hub Bearing Replacement Odyssey

Buoyed by the pre-assembled design of hub bearings, DIY enthusiasts find solace in the simplicity of replacement endeavors, heralding a saga of convenience and efficacy. By following trusted repair guides and adhering to safety protocols, DIY enthusiasts can navigate the complexities of bearing replacement with confidence and precision, thus embracing the ethos of self-reliance and resourcefulness in the realm of automotive maintenance.

Embracing Professionalism: The Panacea for Complex Bearing Replacements

Championing Professionalism: Advocating for Expert Interventions

In the realm of complex bearing replacements, the imprimatur of professionalism reigns supreme, ensuring meticulous craftsmanship and unparalleled efficacy. By entrusting their vehicles to the care of seasoned professionals, vehicle owners can enjoy peace of mind and assurance, thus fostering a culture of trust and reliability in the automotive landscape.

Navigating the Terrain of Trustworthiness: Selecting Reliable Service Centers

With many automotive sanctuaries adorning the urban landscape, discerning the beacon of trustworthiness is paramount. This task is not just about finding a service center but establishing a symbiotic relationship steeped in reliability and assurance. Knowing which centers prioritize quality and customer satisfaction can save time and prevent potential issues. Therefore, it becomes essential to conduct thorough research, seek recommendations, and perhaps even visit a few centers to gauge their professionalism and expertise.

A Calculated Discourse: Analyzing Cost Dynamics

Balancing the Scales: Cost Considerations in Bearing Replacements

The fulcrum of cost dynamics pivots between the realms of DIY endeavors and professional interventions, heralding a journey rife with deliberation and pragmatism. Evaluating the financial implications of each option requires a careful analysis of not just immediate expenses but long-term costs associated with potential errors or subpar repairs. While DIY projects might seem cost-effective initially, they can incur additional expenses if done incorrectly. Conversely, professional services, though pricier upfront, often come with warranties and guarantees that safeguard against future costs.

Cultivating Bearing Longevity: A Testament to Prudence

Nurturing Bearing Lifespans: The Quintessence of Pragmatism

Embracing a regimen of regular inspections, meticulous lubrication, and proactive maintenance rituals, vehicle owners pave the path toward bearing longevity. Such practices are not mere recommendations but essential actions that significantly enhance the lifespan and performance of bearings. Regular maintenance helps in early detection of potential issues, which can be addressed before they escalate into major problems. By prioritizing these preventative measures, one can ensure a saga of resilience and dependability for their vehicle’s bearings.

Illuminating the Path Ahead: FAQ Insights and Real-Life Experiences

Gleaning Wisdom from the Fount of Experience

Real-life anecdotes serve as poignant reminders of the importance of proactive bearing maintenance. These stories highlight the tangible benefits of staying informed and vigilant about vehicle upkeep. By sharing experiences, vehicle owners can learn from each other’s mistakes and successes, fostering a culture of enlightenment and preparedness. This collective wisdom not only provides practical insights but also reinforces the significance of regular maintenance and timely interventions.

DIY Wheel Bearing Replacement

For those who enjoy tackling vehicle maintenance themselves, replacing wheel bearings is an option that combines hands-on learning with potential cost savings. This approach, however, requires a good understanding of the vehicle’s mechanics and confidence in one’s ability to perform the task correctly. It is essential to follow detailed guides and take necessary precautions to avoid any mishaps during the replacement process.

Necessary Tools and Equipment

Gather the essential tools and equipment, such as a jack, jack stands, socket and ratchet set, and wheel bearing grease. Each tool plays a crucial role in ensuring the job is done safely and effectively. Investing in high-quality tools can also make the process smoother and reduce the risk of damaging your vehicle.

Step-by-Step Guide for Replacing Wheel Bearings

- Safely lift and secure the vehicle. Ensuring the vehicle is stable before starting any work is crucial to prevent accidents.

- Remove the wheel and brake caliper. This step allows access to the wheel hub assembly where the bearings are located.

- Access the wheel hub assembly. Carefully navigate through the components to reach the old bearing.

- Remove the old wheel bearing. This process might require some effort and the use of specific tools designed for bearing removal.

- Install the new bearing and reassemble the components. Follow the reverse order of disassembly to ensure everything is properly reinstalled.

Safety Precautions for DIY Enthusiasts

Always use the proper safety equipment, such as gloves and safety glasses, to protect yourself during the repair process. Following a trusted repair guide for guidance is also vital to avoid any missteps. Additionally, never rush the process; taking your time ensures that each step is completed correctly and safely.

DIY Hub Bearing Replacement

DIY hub bearing replacement is typically more straightforward due to the pre-assembled design.

This pre-assembled design simplifies the process significantly, making it more accessible for those with less mechanical experience. The ease of replacement reduces the chances of making errors, ensuring a smoother repair experience.

Tools Required for Replacing Hub Bearings

Assemble the necessary tools and equipment, including a jack, jack stands, wrench and socket set, and a torque wrench. These tools are fundamental for performing the replacement correctly. Proper preparation with the right tools can save time and effort during the actual replacement process.

Step-by-Step DIY Guide for Hub Bearings

- Safely lift and secure the vehicle. Ensure stability to prevent any accidents.

- Remove the wheel and brake components. This allows clear access to the hub assembly.

- Unbolt and replace the entire hub assembly. The straightforward nature of this step is due to the pre-assembled design.

- Reassemble the components in reverse order. Ensure all parts are securely fitted to avoid any issues later.

Safety Tips for DIY Mechanics

Prioritize safety by wearing proper gear such as gloves and safety glasses to protect yourself. Follow the manufacturer’s guidelines for your vehicle to ensure you are performing the replacement correctly. Taking these precautions helps ensure the job is done safely and effectively.

Professional Wheel Bearing Replacement

Opting for professional service is often recommended, especially for complex wheel bearing replacement. Professional mechanics have the expertise and experience to handle these tasks efficiently and accurately. This option often provides peace of mind, knowing that the job is done correctly and safely.

Reasons to Opt for Professional Service

Professional mechanics possess the expertise and experience to handle bearing replacement effectively. Their training and knowledge can prevent common mistakes that might occur during a DIY attempt. They also have access to specialized tools and equipment, ensuring a higher quality of work.

Identifying a Trustworthy Auto Repair Shop

Research and select a reputable automotive repair shop. Look for certifications and customer reviews to gauge the quality of service. Personal recommendations from friends or family can also provide valuable insights into the reliability of a shop.

Cost and Warranty Aspects

Professional service may cost more than a DIY approach but ensures quality work. Inquire about warranties covering parts and labor for added peace of mind. These warranties can protect you from future expenses related to the repair, making the initial investment worthwhile.

Professional Hub Bearing Replacement

Professional hub bearing replacement offers assurance and safety. The expertise of professional mechanics ensures that the replacement is done correctly, reducing the risk of future issues.

Benefits of Professional Hub Bearing Replacement

- Professional mechanics provide efficient and reliable service. Their expertise is crucial for complex repairs, ensuring that all aspects of the replacement are handled properly. This can save time and prevent potential problems that might arise from an improper DIY job.

Selecting a Reliable Mechanic or Service Center

Carefully research local repair shops to find a trustworthy professional. Seek recommendations from friends or family for added assurance. Look for reviews and ratings online to get a sense of the service quality and customer satisfaction.

Cost and Warranty Considerations

High-quality service typically includes warranties on both parts and labor. Compare costs and the terms of available warranties to make an informed decision. These warranties can provide long-term protection and peace of mind, ensuring that your investment is safeguarded.

Cost Comparison: DIY vs. Professional Replacement

To make an informed decision, it’s essential to compare the costs associated with DIY and professional bearing replacement. This analysis helps determine which option is more practical and cost-effective in the long run.

Analyzing Expenses for Wheel Bearing Replacement

Take into account the cost of parts, tools, and your time when considering a DIY approach. While DIY might seem cheaper initially, the value of your time and the risk of potential mistakes should be factored in. Professional service includes labor costs and warranty coverage, providing a more comprehensive solution.

Weighing Costs of Professional Hub Bearing Replacement

Professional hub bearing replacement is generally more cost-effective in the long run. The expertise and efficiency of professionals reduce the risk of errors and additional costs. Weigh the benefits of safety and expertise against the added expense to make a well-informed decision.

Maintenance Tips to Extend Bearing Life

Ensuring your vehicle’s bearings last as long as possible is essential for your safety and your vehicle’s performance. Regular maintenance can prevent premature wear and extend the lifespan of your bearings.

Regular Inspections and Lubrication

Periodically inspect your bearings for signs of wear. This proactive approach can help identify issues early before they become major problems. Properly lubricate bearings as necessary, following the manufacturer’s guidelines to ensure optimal performance.

Keeping Bearings Clean and Protected

Prevent debris and contaminants from compromising your bearings. Use protective covers where applicable to shield the bearings from harm. Regular cleaning and maintenance can prevent damage and extend the life of your bearings.

Best Practices for Prolonging Bearing Lifespan

Follow the manufacturer’s guidelines for bearing maintenance. Be proactive in addressing any signs of wear or issues as soon as they arise. This diligent approach can prevent major problems and ensure your bearings remain in good condition.

Frequently Asked Questions (FAQs) on Bearings

A failing wheel bearing typically manifests through unusual noises such as grinding or humming coming from the wheel area. Other signs include uneven tire wear, vibration in the steering wheel, and the vehicle pulling to one side while driving.

Wheel bearings typically last between 85,000 to 100,000 miles. However, their lifespan can vary depending on driving conditions, vehicle type, and maintenance practices.

It is not recommended to drive with a noisy wheel bearing. Ignoring the noise can lead to complete bearing failure, which can result in loss of wheel control, posing a significant safety risk.

To check the condition of your wheel bearings, listen for unusual noises while driving, check for excessive play in the wheel, and inspect the bearing for any signs of wear or damage during regular maintenance checks.

Premature failure of wheel bearings can be caused by several factors, including poor lubrication, contamination by dirt or water, excessive load, and improper installation. Regular maintenance can help prevent these issues.

A wheel bearing is a set of steel balls or rollers held together by a metal ring, allowing the wheel to spin smoothly. A hub bearing, or hub assembly, includes the wheel bearing but also integrates with the wheel hub and sometimes the ABS sensor, providing a more comprehensive unit.

Signs that your hub bearings need to be replaced include a roaring or grinding noise from the wheel area, the ABS light turning on, and excessive wheel play. Vibration and pulling to one side while driving can also indicate hub bearing issues.

In many modern vehicles, the hub assembly is designed as a single, sealed unit, meaning the entire assembly must be replaced rather than just the bearing. This design simplifies installation and enhances durability.

It is advisable to inspect your wheel and hub bearings at least once a year or during regular vehicle maintenance services. Additionally, they should be checked if you notice any symptoms of wear or damage.

Professional replacement ensures that the job is done correctly using the right tools and techniques, reducing the risk of further damage. Professional mechanics can also identify and address related issues that might not be evident to the average vehicle owner, ensuring overall vehicle safety and performance.

Conclusion

In conclusion, an in-depth understanding of the distinctions between wheel bearings and hub bearings is critical for maintaining the safety and performance of your vehicle. Regular maintenance, timely replacements, and informed decision-making are the keys to a smooth and secure ride. Whether you choose to take a DIY approach or opt for professional service, ensuring the health of your bearings is paramount for a worry-free driving experience.