Custom Bearings

Table of Contents

Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (28)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Custom Bearing Solutions

FHD Bearings’ engineers work closely with our customers to deliver unique bearing solutions with optimized features to meet demanding application challenges. Custom bearings are used in a wide range of applications, including aerospace, automotive, industrial, and medical equipment. These bearings can be made from a variety of materials, including steel, ceramics, and plastics, and can be designed to handle different types of loads, such as radial, axial, or a combination of both.

Facilities

FHD Bearings: Elevating Your Bearings Experience:

In the intricate landscape of industrial components, finding the right bearing goes beyond the standard – it’s about tailored solutions that add value across the entire design, production, and supply chain management spectrum, ultimately optimizing costs.

Customization Excellence

At FHD Bearings, we redefine the bearing paradigm through our specialized focus on design, development, and manufacturing of custom, made-to-order bearings. Our expertise extends across various industries and applications, offering low- to mid-volume solutions that align precisely with your unique requirements.

Unparalleled Customization

Size, Design, Features, and Materials: Tailor every aspect of your bearings with FHD’s customization capabilities. Enjoy significantly shorter lead times compared to industry peers.

Interchanges and Precision Components: Beyond custom bearings, we manufacture interchanges for industry-standard bearings, individual bearing parts, and precision components essential to your application.

Comprehensive Custom Solutions

Explore a spectrum of custom offerings, including:

- Deep Groove Ball Bearings – Imperial

- Taped Roller Bearings – Imperial

- Cylindrical Roller Bearings – Non-standard

- Thrust Ball Bearings – Non-standard

- Thrust Roller Bearings – Non-standard

- Stainless Steel Bearings – Non-standard

Seamless Process

Navigating the custom bearing creation process is simple with FHD Bearings:

- Provide Specifications: Whether it’s an obsolete bearing part number, dimensions, or specific application requirements, we work with your input.

- Detailed Quotation: Receive a transparent, detailed quote accompanied by a written description of our offerings.

- Approval Drawings: Once the price aligns with your expectations, we produce drawings for your approval, ensuring a collaborative and precise customization journey.

Your Partner in Precision

FHD Bearings stands ready to be your trusted partner in precision. Elevate your bearing experience with our commitment to customization, efficiency, and excellence.

Benefits of Custom Bearings

- Higher Load Capabilities

- Improve safety

- Reduce Maintenance Requirement

- Material Capability: 52100, 440C, Silicon Nitride, Bronze,Nylon and more

- Seal Material Capability: Nitrile, Polyacrylic, Fluorelastomer and more

- Customer Made-To-Order Experts

- Made in the USA requirements / DFARS / NAFTA compliant

Quality of Service

Engineering

At FHD Bearings, our seasoned engineers are dedicated to elevating your design processes. Drawing upon their extensive knowledge of your product and industry, they streamline operations to save both time and costs. A Kilian-engineered design entails a meticulous examination of crucial factors such as load, speed, size, lubrication, and environment.

Our engineers collaborate seamlessly with our manufacturing and quality teams to ensure that we not only meet but exceed all your specific requirements. At FHD, our commitment is unwavering – we go above and beyond to satisfy our customers’ needs, delivering engineering excellence that sets your products apart in the market.

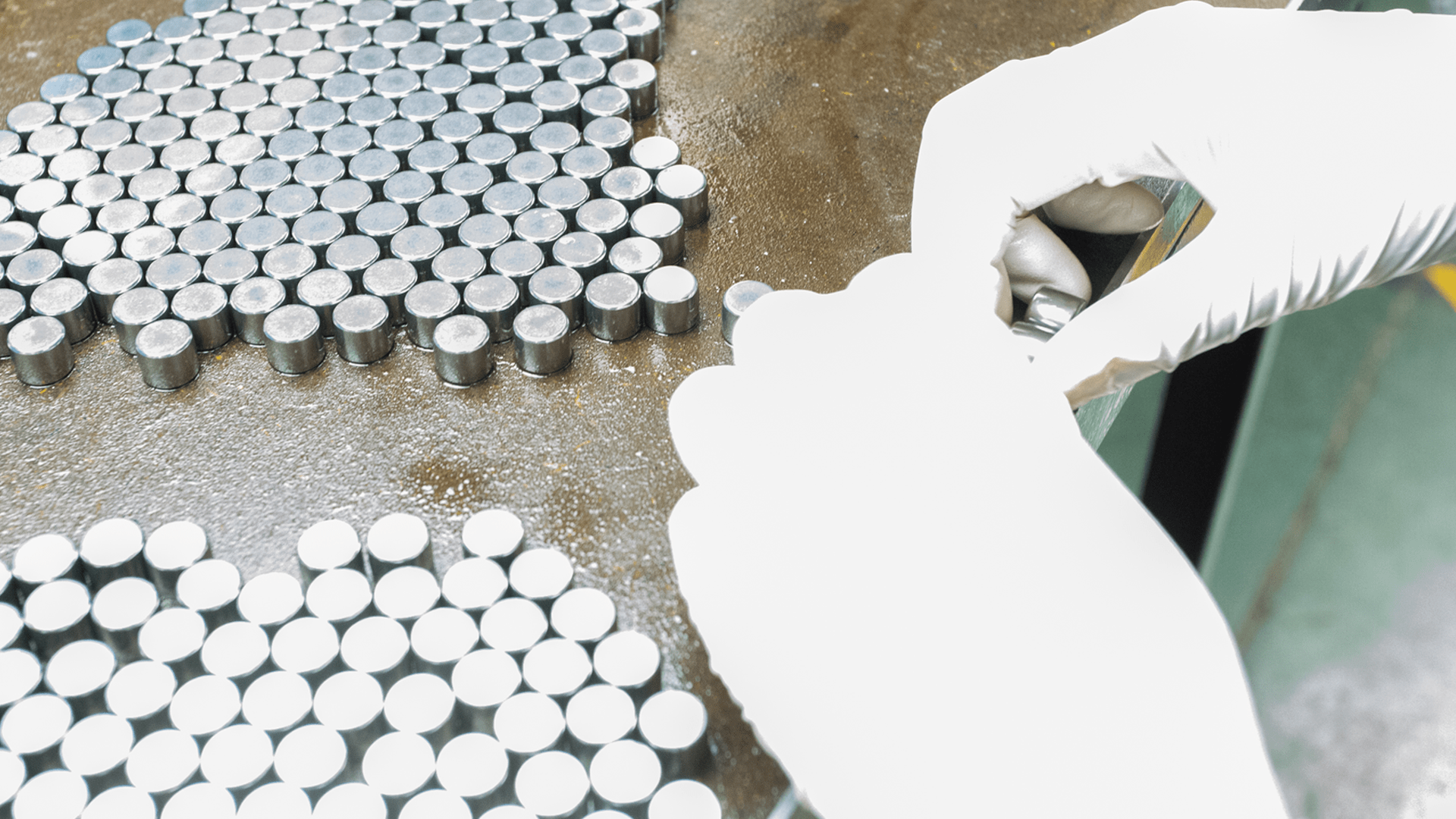

Prototyping

At FHD Bearings, we take pride in our unparalleled expertise in swiftly and cost-effectively developing cutting-edge products tailored to meet our customers’ unique requirements. Our skilled engineers utilize CAD technology to craft innovative designs within mere days, followed by the prompt creation of prototypes within weeks.

These prototypes are meticulously crafted using production equipment that precisely mirrors our actual manufacturing processes. To ensure the utmost quality, our products undergo rigorous durability testing, validating the accuracy of our analytical performance predictions. This commitment to innovation and quality sets FHD Bearings apart as your reliable partner in delivering top-notch solutions.

Customer Services

At FHD Bearings, our commitment to exceptional customer service sets us apart. Your dedicated customer service representative, well-acquainted with your account, is meticulously trained to address your inquiries promptly and effectively. Situated right within our manufacturing plant, this representative ensures a seamless connection between your needs and our capabilities.

Furthermore, your local field sales engineer functions as a valuable technical resource, collaborating closely with our skilled engineering staff. This synergy between on-site support and technical expertise guarantees that your requirements are not only met but exceeded. At FHD Bearings, we take pride in offering a comprehensive support system that goes beyond conventional standards, reinforcing our commitment to your satisfaction.

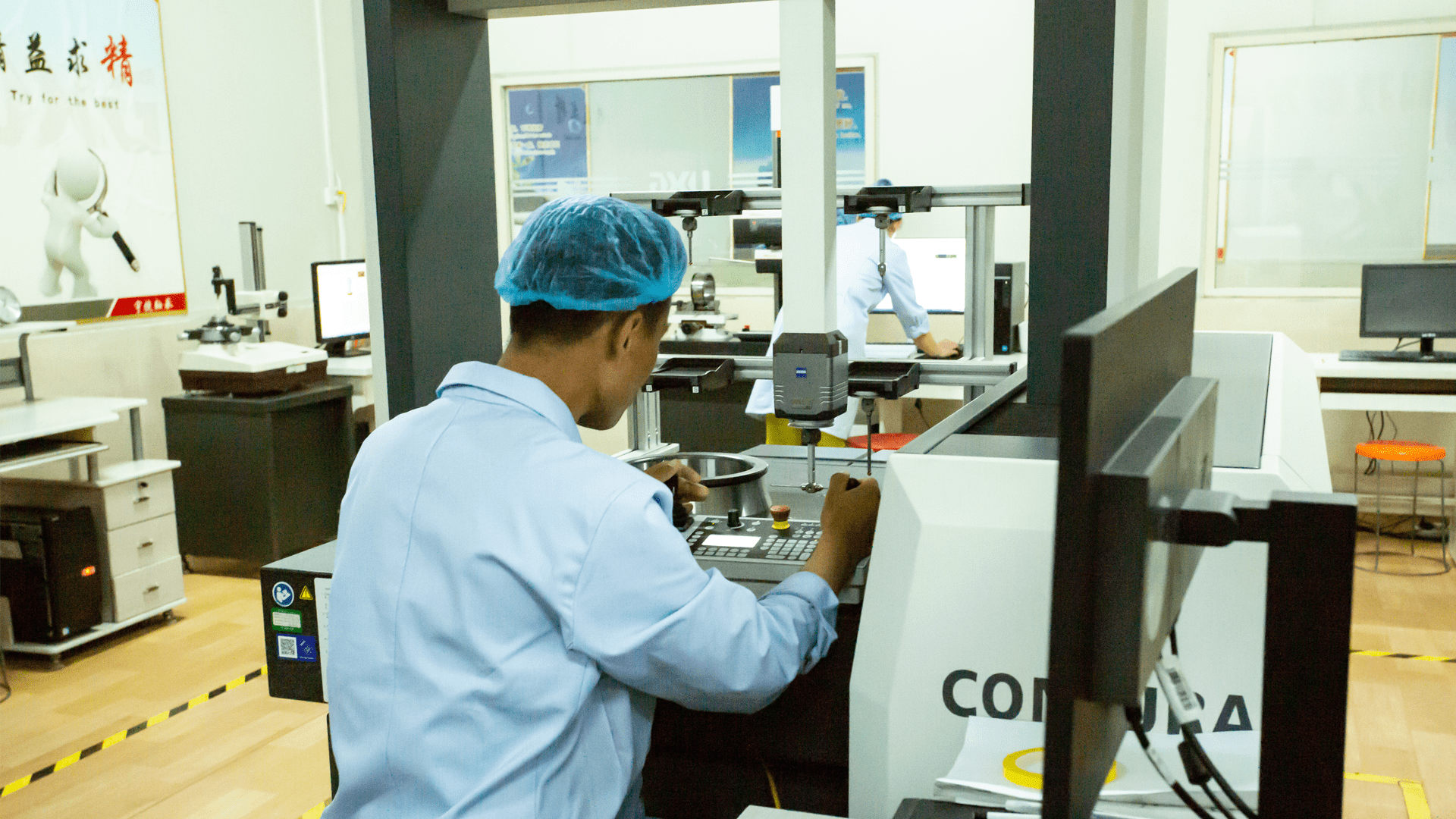

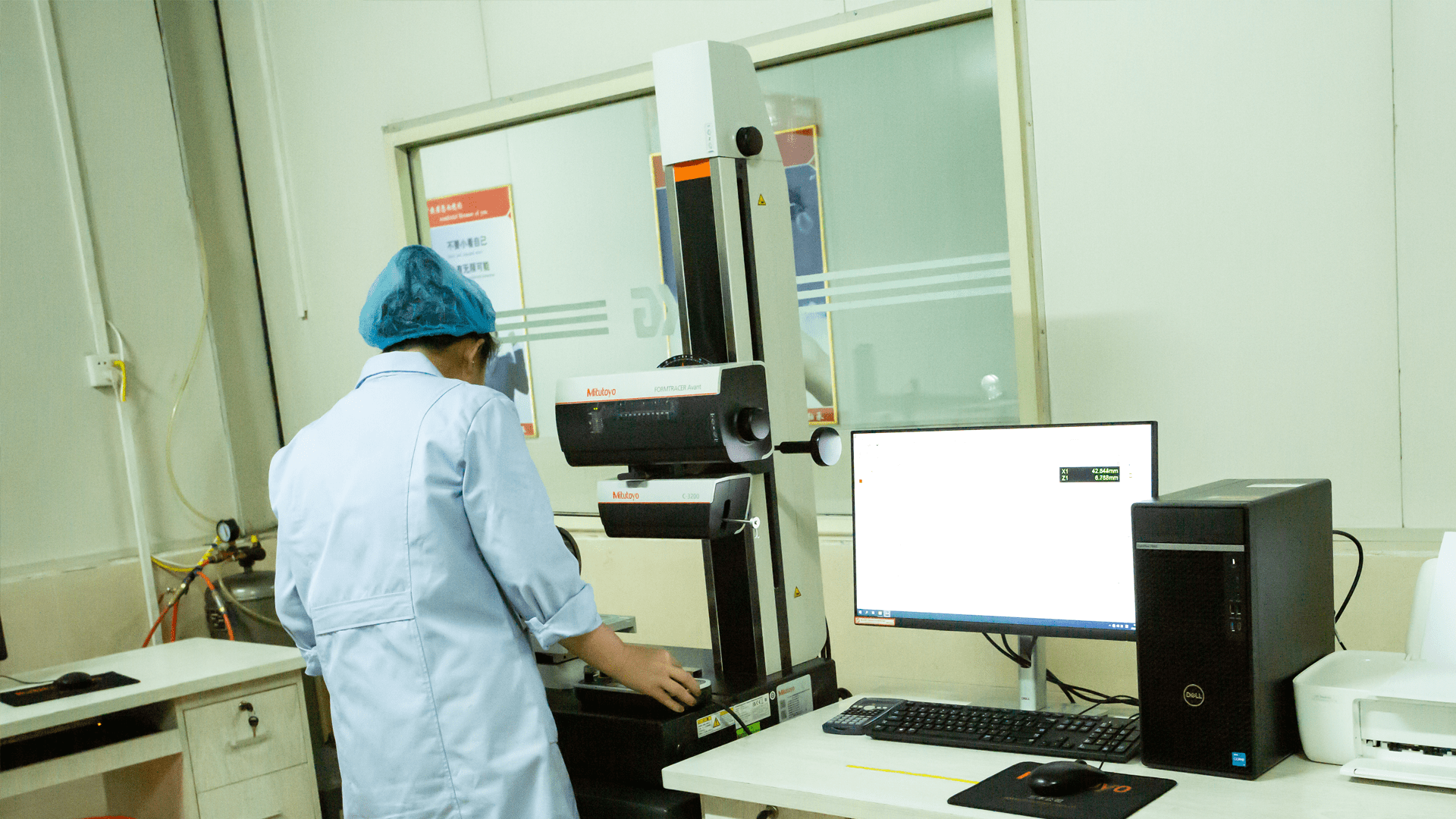

Manufacturing Reliability

At FHD Bearings, we take pride in being the backbone of reliability for automotive, aircraft, and medical products globally through our precision-machined bearings.

Our meticulous engineering process, incorporating design for manufacturability, guarantees both cost efficiency and unparalleled product reliability. We understand the critical importance of precision in your applications.

Behind our commitment to excellence are our highly skilled technicians who operate best-in-class machinery. We invest in the latest automation and electronic sensors to uphold the integrity of critical assembly operations.

Partner with FHD Bearings for precision, efficiency, and unmatched reliability in every bearing we manufacture. Your trust is our driving force.

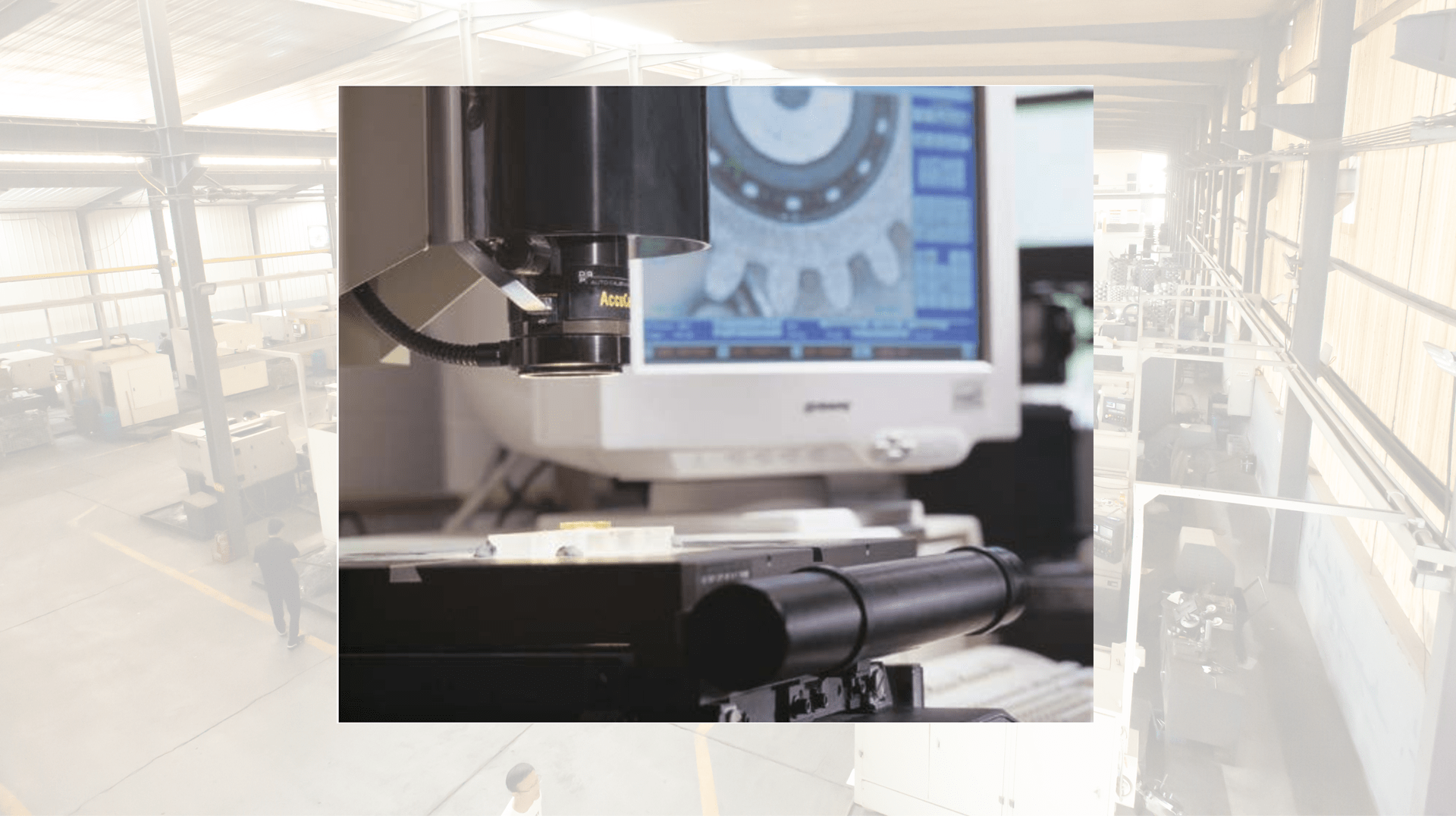

Quality Assurance

At FHD Bearings, we are unwavering in our commitment to minimizing variation across every product and process, while consistently elevating our quality standards. Our quality systems are registered under ISO 9001:2015 / IATF 16949:2016, reflecting our dedication to excellence.

Our meticulous quality process initiates at the design stage, guided by a comprehensive Control Plan. This plan encapsulates well-documented procedures that are not just communicated but diligently executed and verified. At FHD, we empower our operators, assigning them the responsibility for the quality of their work. They leverage Statistical Process Control (SPC) to ensure that their processes remain firmly “in control.”

This unwavering dedication to quality assurance sets FHD Bearings apart, providing you with the assurance that each product adheres to the highest standards from design to delivery.

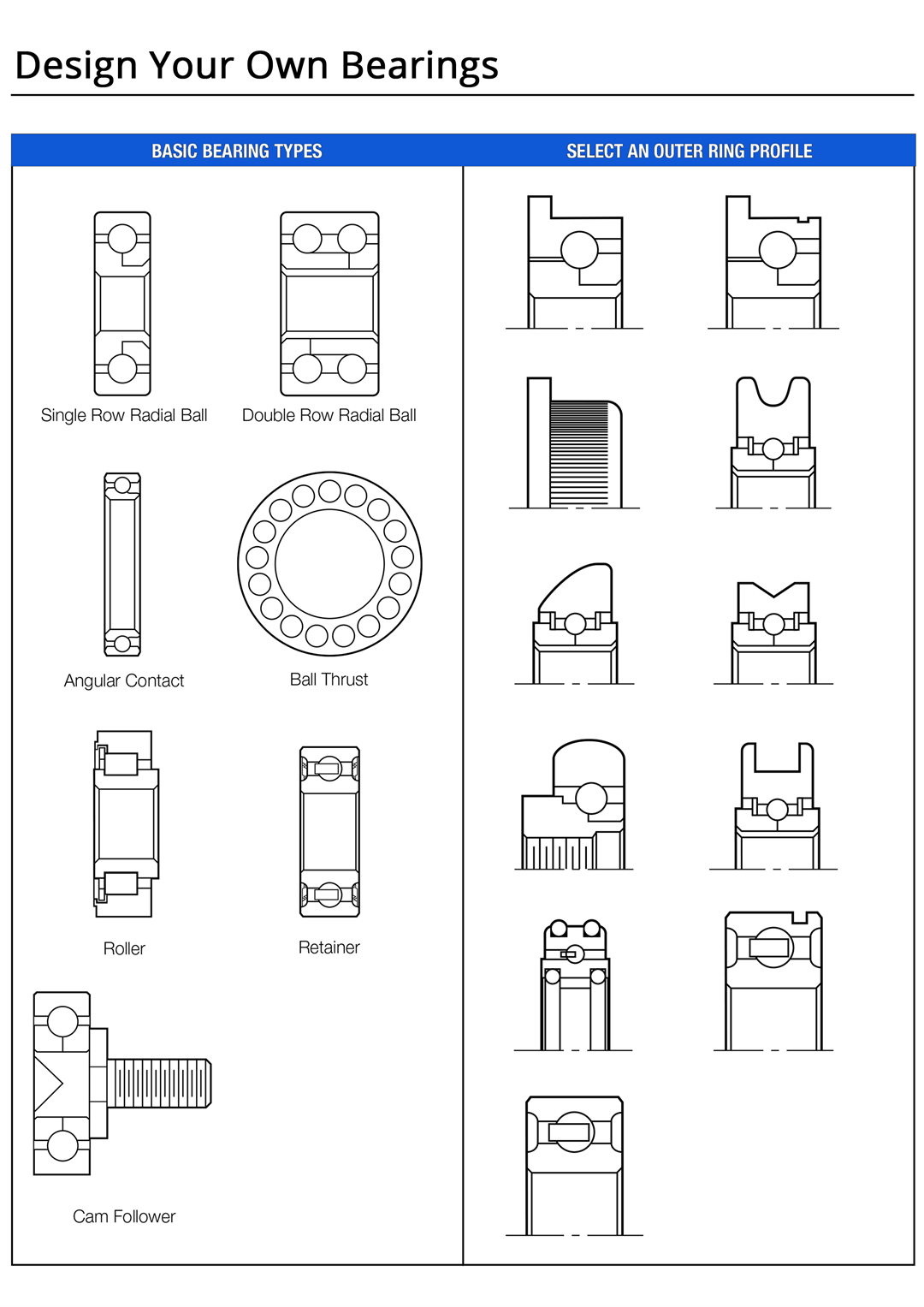

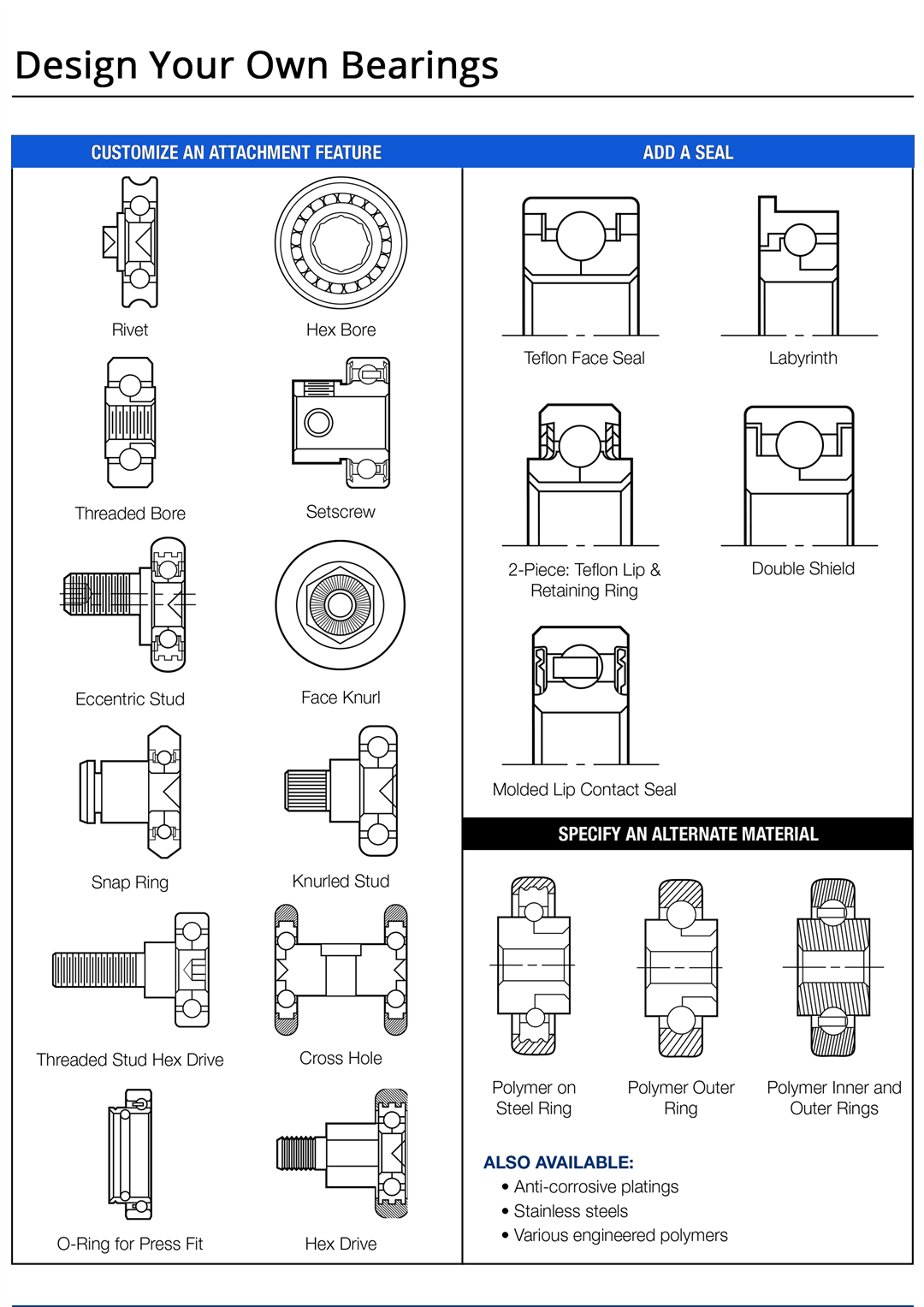

Design Your Own Bearings

Optional Bearing Components

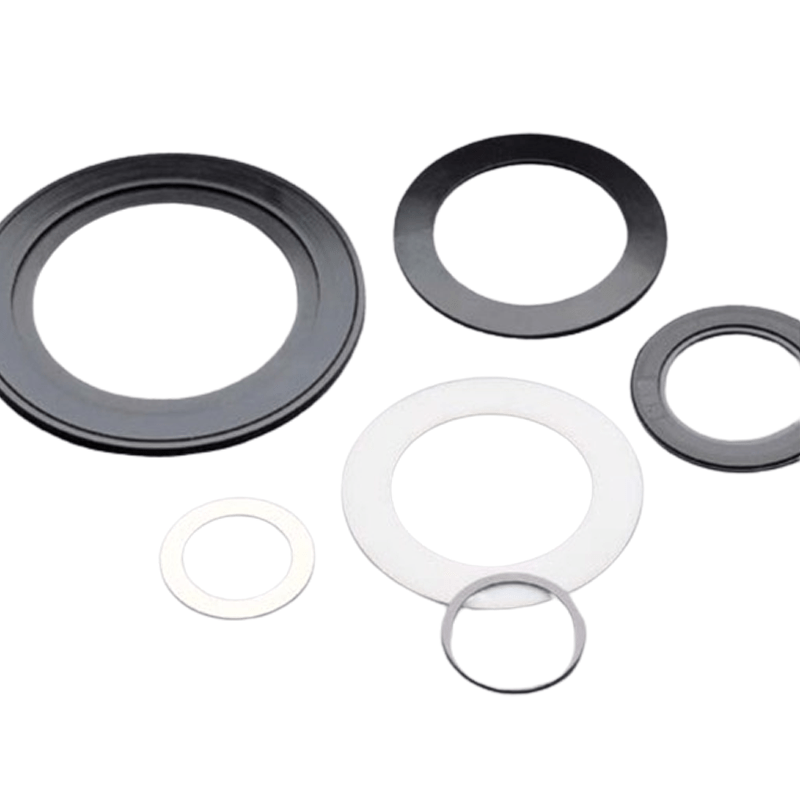

A broad assortment of seal styles and materials is available

Seals

Seals can be added to keep contamination out of our

bearings or to help keep grease in. Various labyrinth

designs offer cost-effective options. Teflon seals are

a choice for low-torque performance. Lip contact

seals can be molded from rubber or thermoplastic for

maximum effectiveness.

Stainless steels, various platings and polymers are available.

Material Options

The majority of our bearings are manufactured from

carbon steel. Various heat treat processes produce

the hardness and case depths required by specific

applications. Special platings and coatings provide the

required corrosion resistance or appearance. We use

stainless steels when severely corrosive environments

are anticipated. Also, engineered polymers can reduce

rolling noise or corrosion. We can form a tire by insertmolding polymers to the steel bearing, or make the

entire bearing of an engineered polymer.

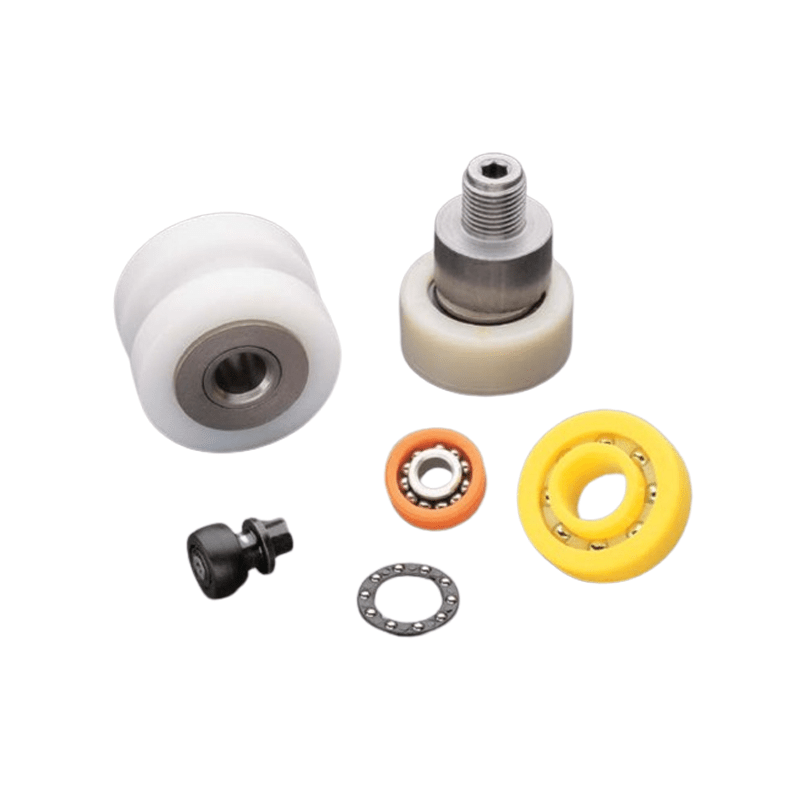

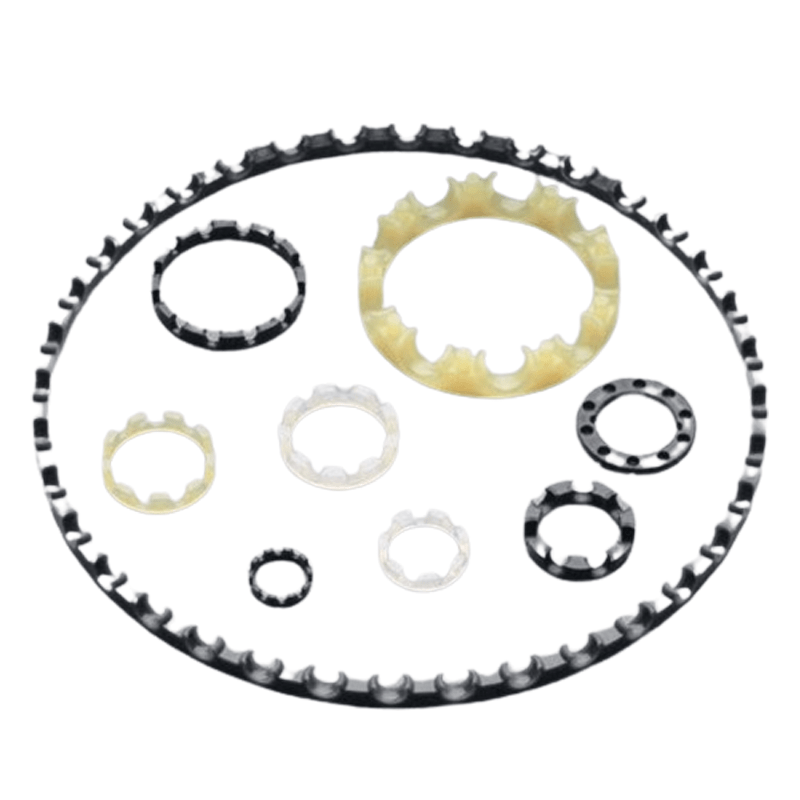

Ball cages allow higher speeds.

Cage-Type Bearings

Nylon finger-style cages are available in many sizes.

The caged design provides better ball guidance,

allowing higher speed capabilities (up to 2000 rpm). By

separating the balls, the cage also provides a quieter

bearing. This design can hold more grease for longer

life in difficult applications.

Roller bearings support higher loads

Ball Bearings

The FHD full-complement design allows the assembly

of the maximum number of balls without a loading slot.

This construction provides the greatest load capacity

while minimizing cost. It is suitable for applications

where noise and speed are not critical.

Roller Bearings

Using rollers instead of balls provides additional load

capacity and stability. A full complement of cylindrical

rollers can be used for most applications.